Steel structure concrete internal-external thermal insulation integration module house

A reinforced concrete and concrete technology, which is applied in thermal insulation, construction, building components, etc., to reduce construction costs, improve construction efficiency, and achieve the effect of good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

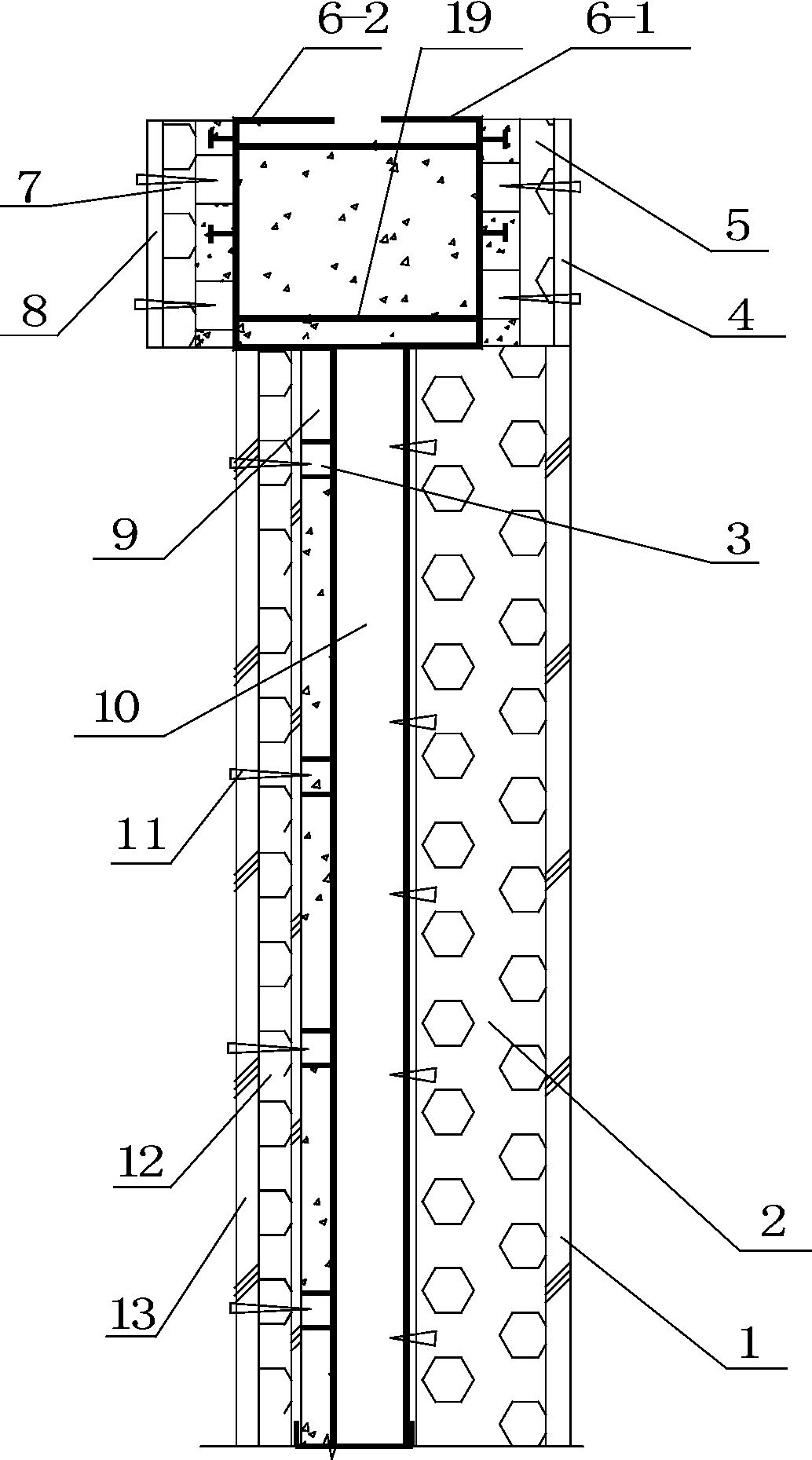

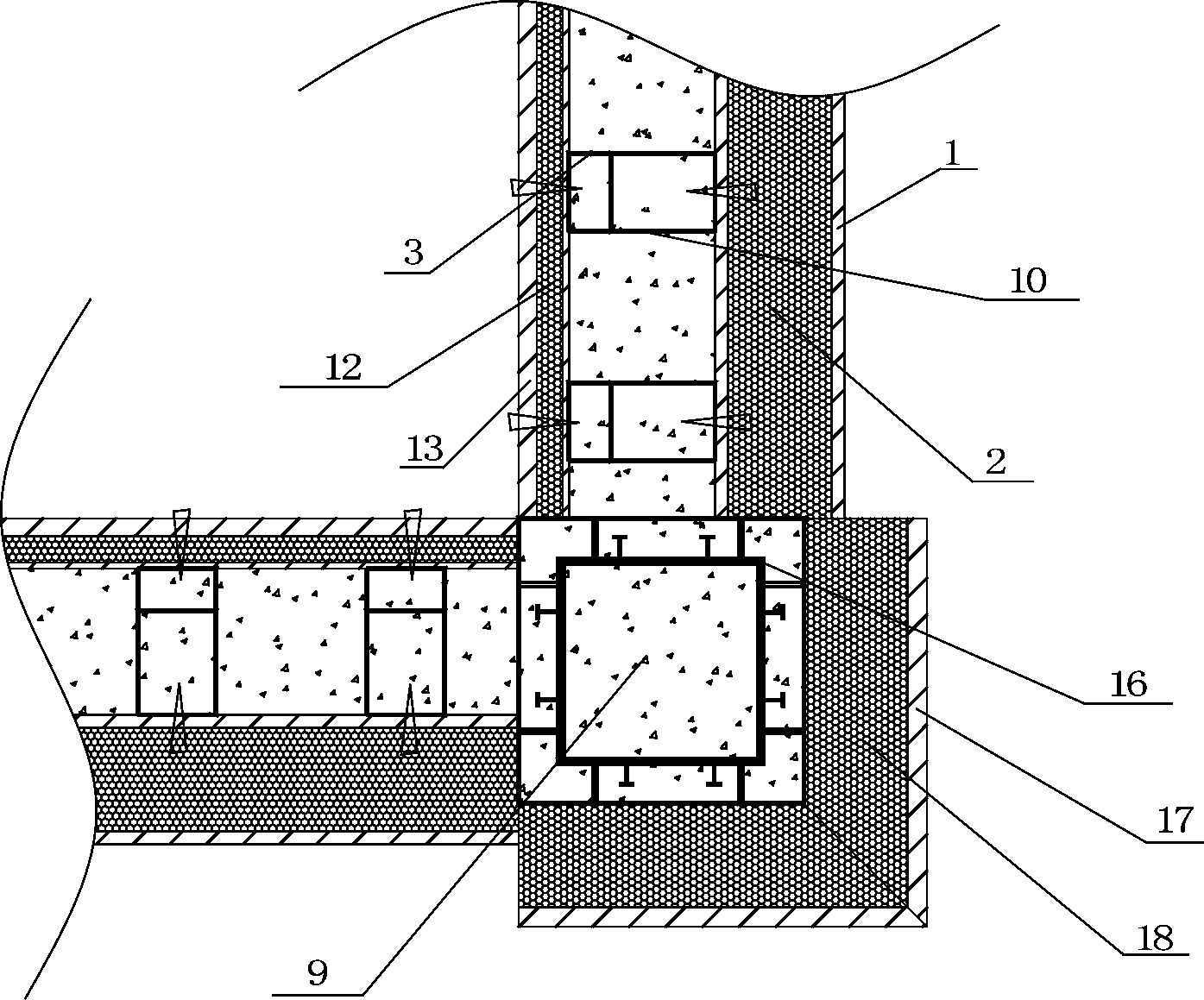

[0030] Below in conjunction with accompanying drawing and construction step implementation further illustrate the present invention.

[0031] Embodiments of the present invention include a reinforced concrete foundation and several shaped steel columns 16 whose bottom ends are installed on the reinforced concrete foundation. The shaped steel columns 16 are hollow steel columns, I-beams or channel steel, and steel rivets 14 are welded around them.

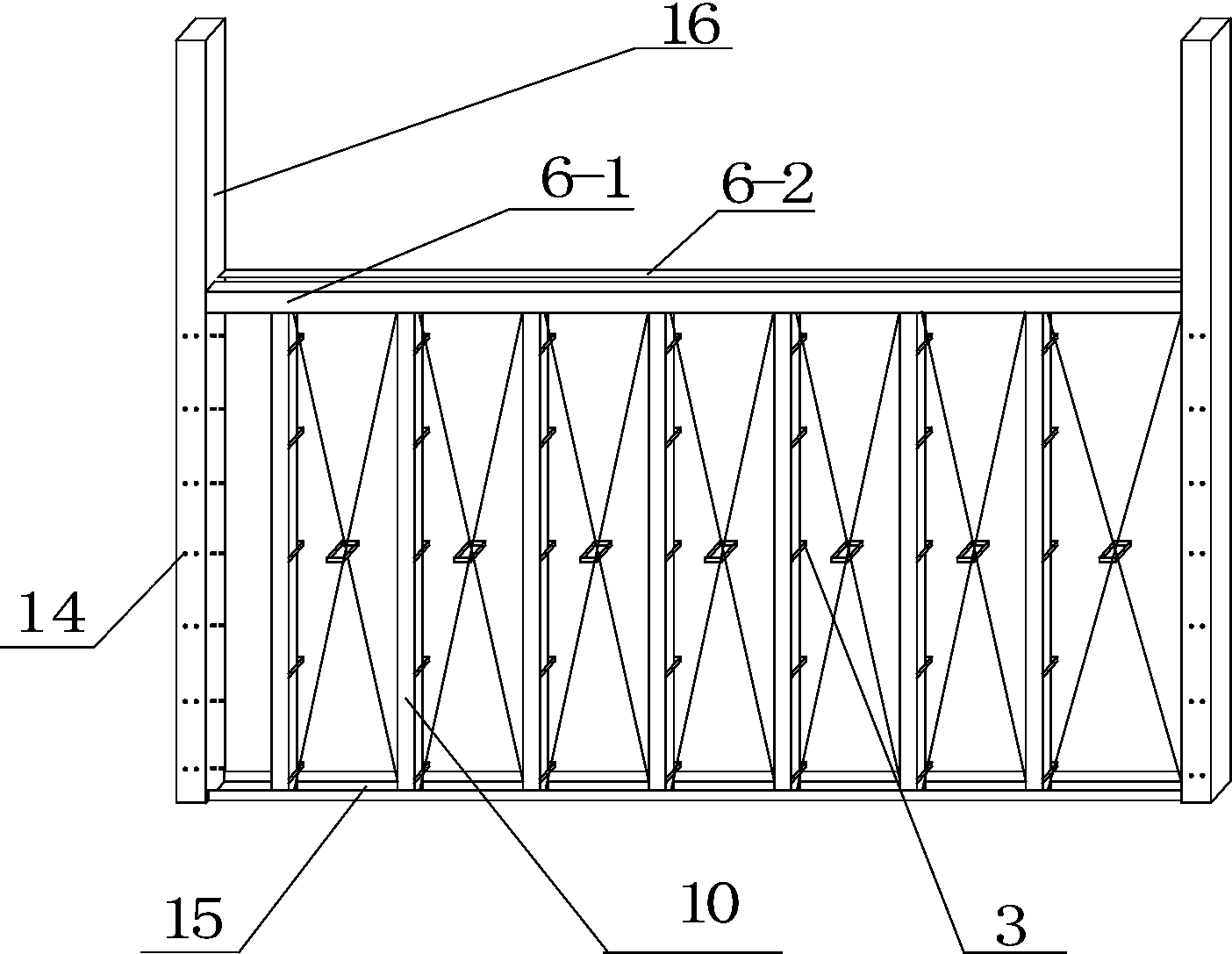

[0032] Such as figure 2 , the lower ends of the two steel columns 16 are connected with transverse steel 15, and the two steel columns 16 are also connected with two outer channel steel 6-1 and inner channel steel 6-2 with opposite openings as the framework of the beam body. Rivets 14 are welded on the outer side of the steel, and a certain gap is left between the two channel steels and the outer side is used as a cement or concrete pouring port; a plurality of longitudinal section steels 10 arranged in parallel at intervals are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com