Wall penetrating body and using method thereof

A wall and corrugated pipe technology, applied in the direction of pipes, pipes/pipe joints/pipes, adjustable connections, etc., can solve the problems of short service life of sealing fillers, unable to meet the requirements of nuclear power plants, etc., and achieve the effect of reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

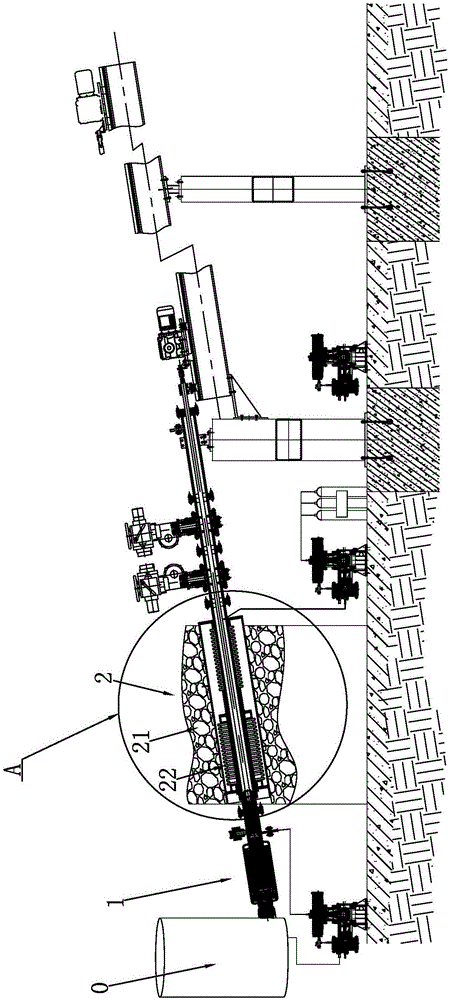

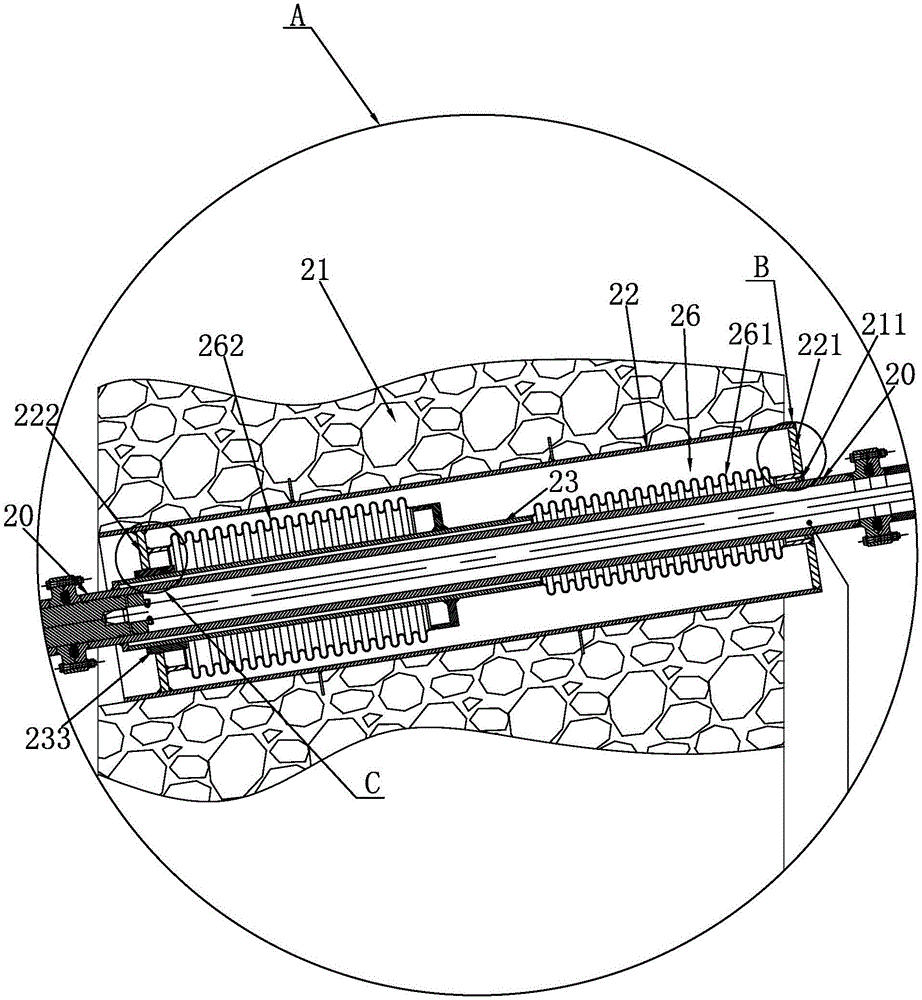

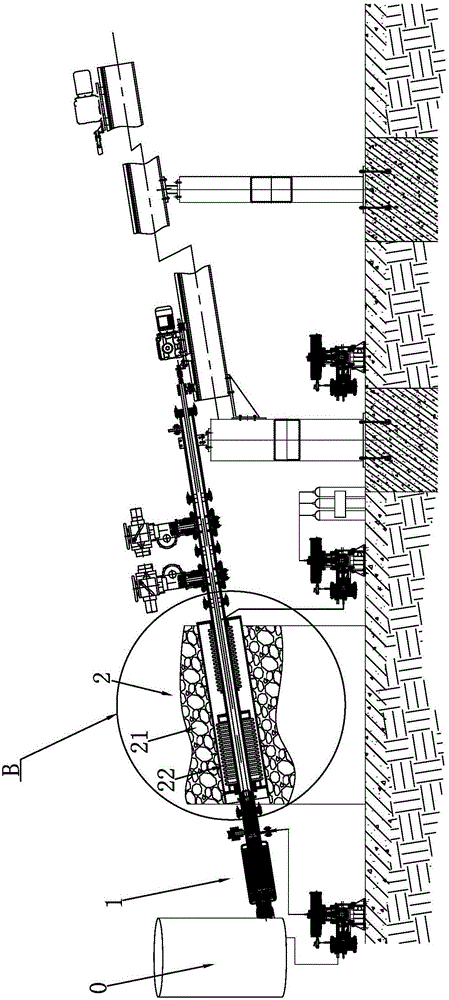

[0044] Such as figure 1 , image 3 shown, see figure 1 , The wall penetrating body of the present invention includes an inner pipe 20 , an outer pipe 22 and a corrugated pipe 26 . A wall-through section 2 is communicated at the sampling outlet reserved for the high-temperature gas-cooled reactor 0, wherein the wall-through section 2 is a sealing part of a sampling device for sampling and observing the substances in the high-temperature gas-cooled reactor 0 arranged in the wall , which is a secondary safety device to block the high-temperature gas-cooled reactor 0 or the connecting pipeline in the wall to prevent leakage. At the same time, the through-wall body 2 also has the potential to prevent the hidden danger of the sealing performance degradation caused by the axial expansion of the pipeline when the high-temperature gas-cooled reactor 0 generates power.

[0045] Such as figure 1 with figure 2 As shown, the wall penetration section 2 includes a wall penetration body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com