Nano-indentation technology-based method for studying boundary phase of composite material

A nano-indentation and composite material technology, applied in the direction of analyzing materials, testing material hardness, measuring devices, etc., can solve problems such as difficult analysis, inability to obtain interface phase width, difficult analysis of transition zone, etc., and achieve the effect of improving experimental accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0024] Example 1 measures the elastic properties of each component of carbon fiber reinforced polymethyl methacrylate (PMMA)

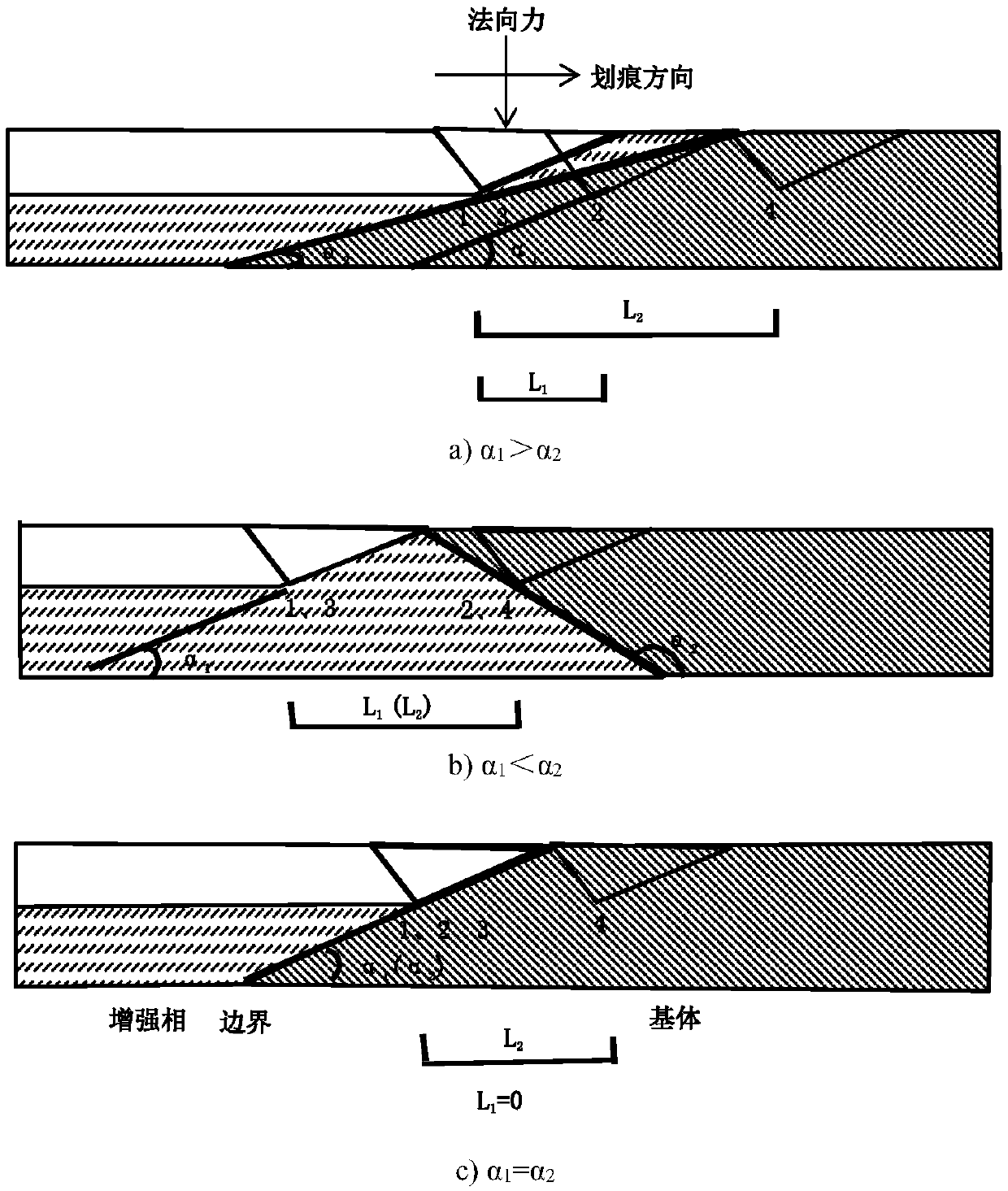

[0025] The elastic properties of each component of PMMA without the influence of the peripheral effect were obtained by applying the method of interfacial phase research of composite materials based on nanoindentation technology. First, the rectangular mixed area of typical carbon fiber-PMMA was located by the optical microscope of the nanoindentation instrument 200 microns × 200 microns. The P value of the feedback adjustment is 5000, the I value is 500, and the D value is 2000. The change speed of the force during the adjustment is ±0.2 mN / s. Set the number of scratches to 11 with an interval of 20 microns. The pre-pressing depth is 2 microns, the pressing speed is 0.2 microns / second, and the scratching speed is 4 microns / second. According to the criterion of contact mechanics, the position of the starting point and the ending point of the interf...

example 2

[0026] Example 2 measures the elastic properties of each component of carbon nanotube fiber bundles reinforced polymethyl methacrylate (PMMA)

[0027] Apply the method of interfacial phase research of composite materials based on nanoindentation technology to obtain the elastic properties of PMMA components reinforced by carbon nanotube fiber bundles without the influence of peripheral effects. First, locate typical carbon nanotube fibers through the optical microscope of the nanoindenter Beam-PMMA rectangular mixing area 200 μm x 200 μm. The P value of the feedback adjustment is 10000, the I value is 500, and the D value is 1000. The change speed of the force during the adjustment is ±0.2 mN / s. Set the number of scratches to 11 with an interval of 20 microns. The pre-pressing depth is 1 micron, the pressing speed is 0.2 micron / second, and the scratching speed is 5 micron / second. According to the criterion of contact mechanics, the position of the starting point and the endi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com