High-temperature Hopkinson tensile bar test system by using two-way electromagnetically-driven synchronous assembly and method

An electromagnetic drive and test system technology, applied in the direction of applying stable tension/pressure to test material strength, applying repetitive force/pulsation force to test material strength, measuring devices, etc., can solve problems such as heat exchange temperature gradient field, and achieve The effect of improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

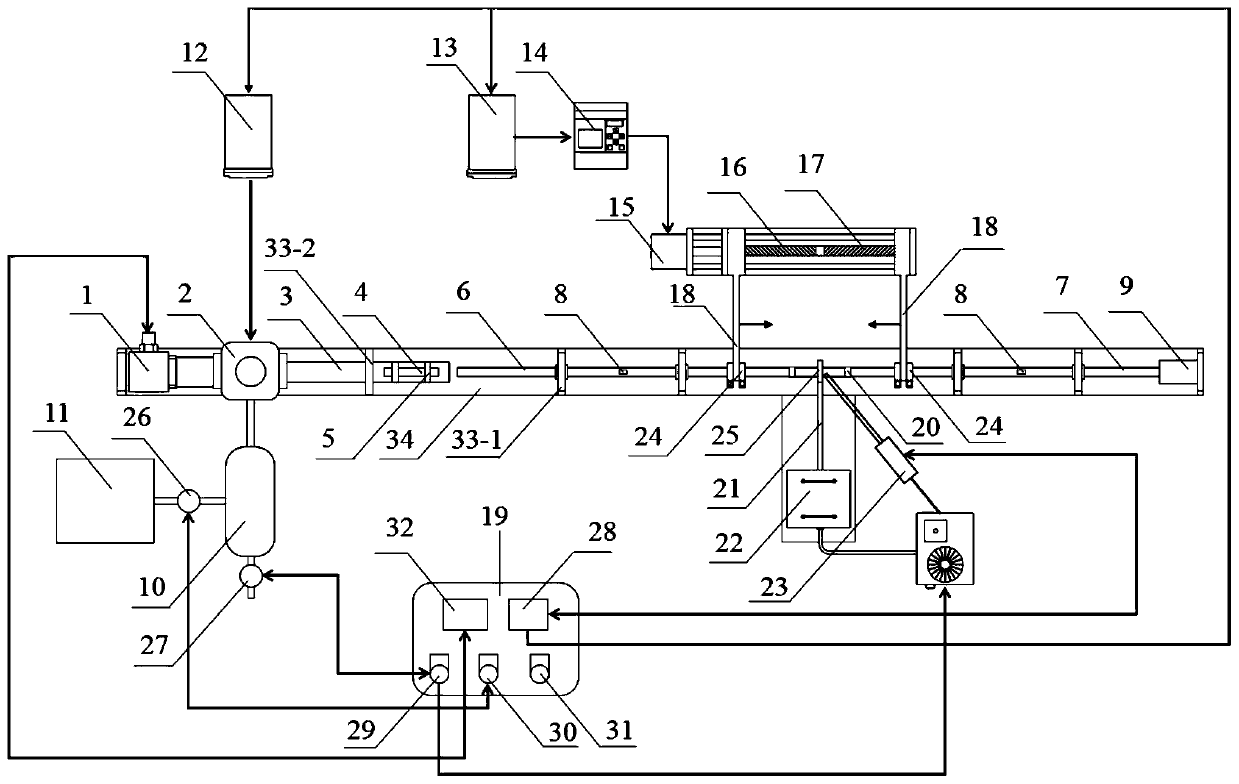

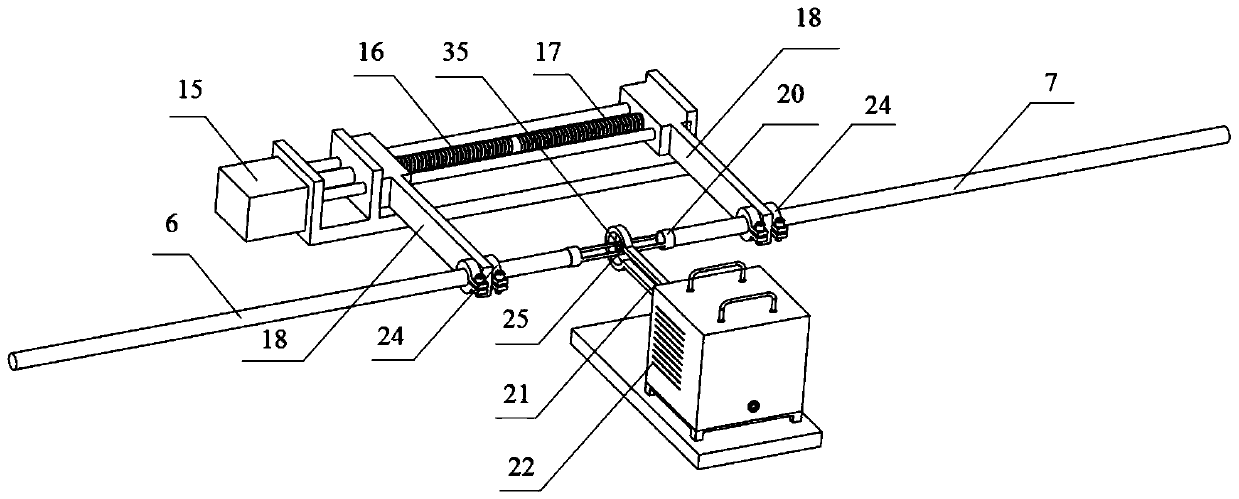

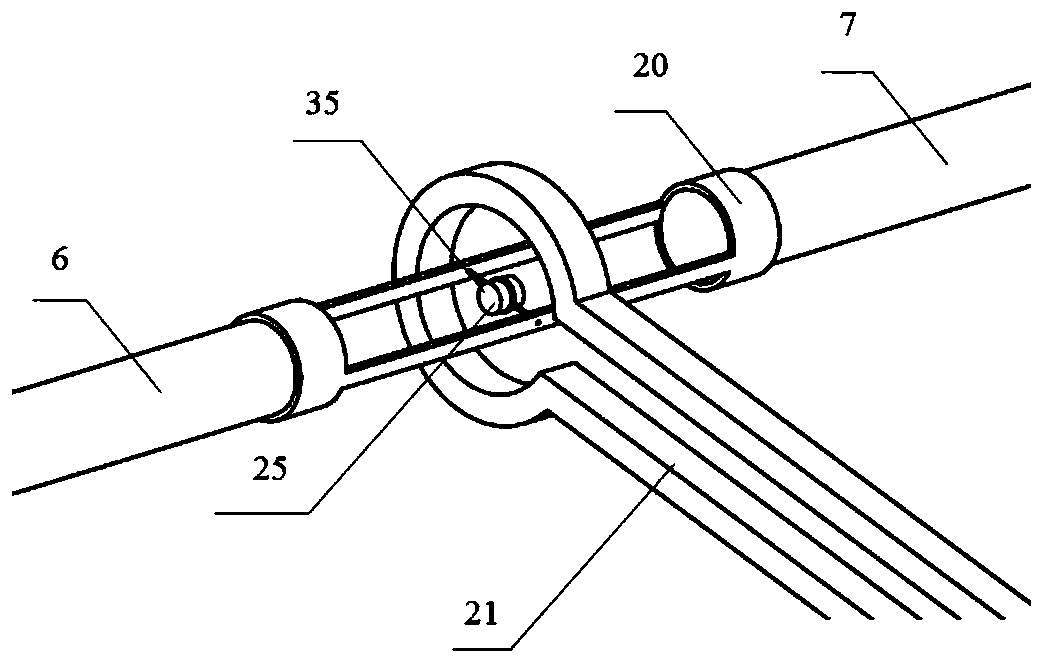

[0037] Specific embodiments: the device includes a pressure sensor 1, an electromagnetic control valve 2, a gun barrel 3, a percussion rod 4, a polytetrafluoroethylene bomb holder 5, an incident rod 6, a transmission rod 7, a strain gauge 8, a damper 9, and a launch gas Chamber 10, air source 11, launching delayer 12, synchronous delayer 13, programmable controller 14, stepper motor 15, forward screw 16, reverse screw 17, driving arm 18, console 19, sliding sleeve Tube 20, induction heating coil 21, high-frequency electromagnetic induction heating machine 22, temperature sensor 23, polytetrafluoroethylene clamp 24, sample 25, booster solenoid valve 26, decompression solenoid valve 27, temperature controller 28, reducing Pressure switch 29, boost switch 30, start switch 31, digital display pressure gauge 32, aluminum alloy sliding support 33-1, aluminum alloy fixed support 33-2, aluminum alloy platform 34, thermocouple wire 35.

[0038]The device in the present invention mainly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com