High-temperature hopkinson rod tensile test device and method capable of precise quantitative electromagnetic control

A technology of electromagnetic control and tensile test, applied in measuring devices, using stable tension/pressure to test material strength, and using repetitive force/pulse force to test material strength, etc., can solve the uncertainty of cold contact time, influence The accuracy of the test results and the low degree of equipment instrumentation have achieved the effect of avoiding the temperature rise of the loading rod, the temperature drop of the sample, and the high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

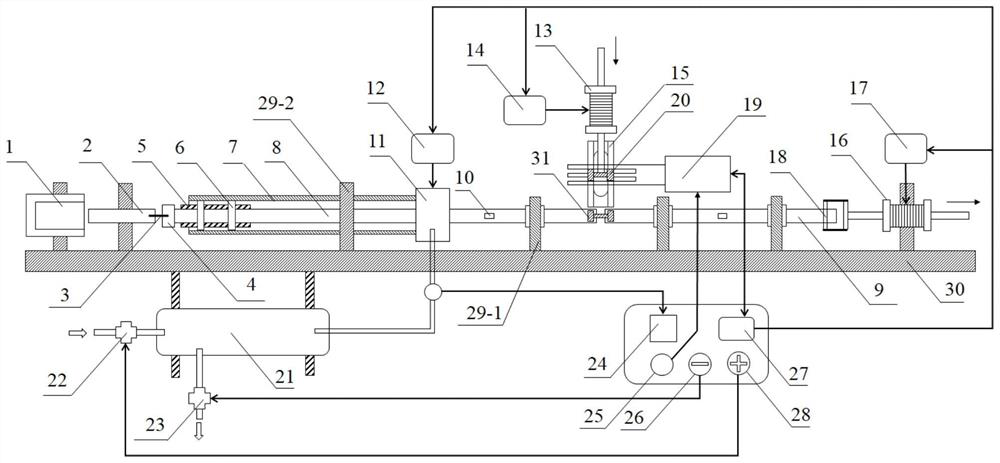

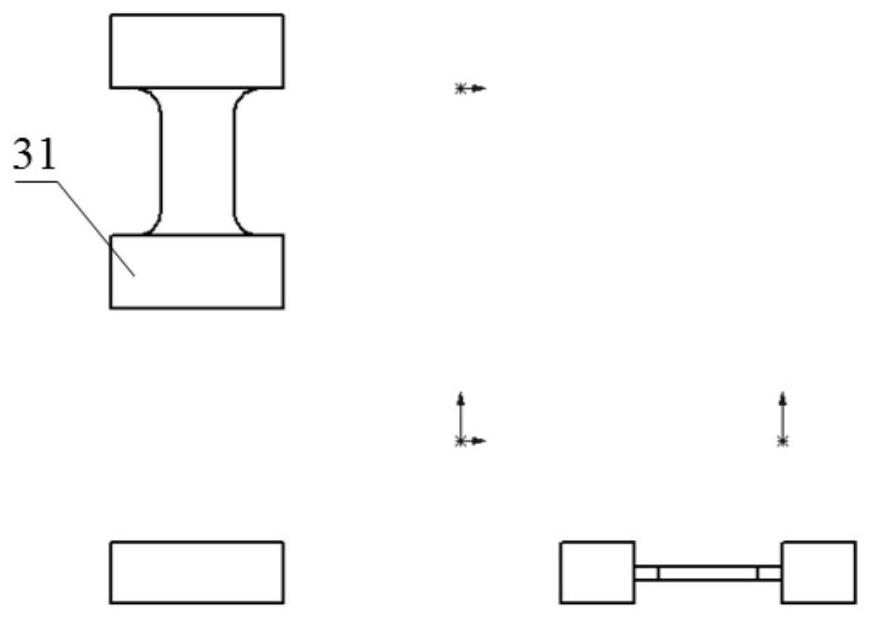

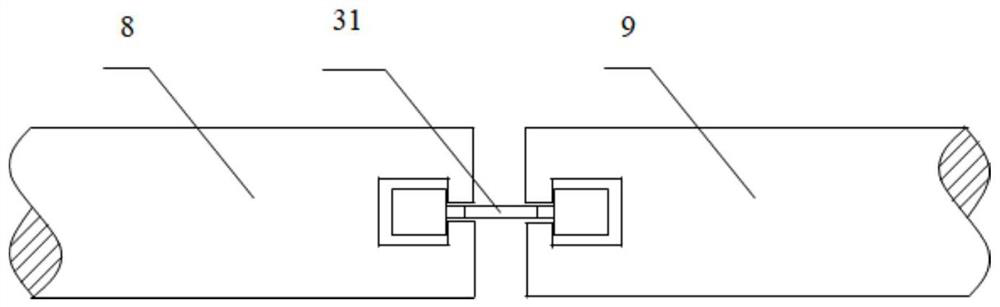

[0046]The specific structure adopted in the present invention: the device is equipped with three sets of high-precision time delay devices, one set of electromagnetic push rod system and one set of electromagnetic dragging system on the traditional separated Hopkinson pull rod, to complete the heating and incident contact of sample 31. Synchronous assembly process of rod 8 and transmissive rod 9. A strain gauge 10 is pasted on the incident rod 8 and the transmission rod 9 to test the strain signal. One end of the incident rod 8 is processed with a flange whose diameter is greater than the diameter of the rod. The impingement tube 5 is a hollow tube, the outer diameter is the same as the outer diameter of the flange, and the inner diameter is equal to the rod diameter. The impact tube 5 is sleeved on the outside of the incident rod 8 and can slide freely along t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com