Multi-stage synchronous screw rod push rod mechanism

A technology of push rod mechanism and lead screw, applied in the field of multi-stage synchronous screw push rod mechanism, can solve problems such as lack of electric mechanism, and achieve the effect of high repeat positioning accuracy transmission control, strong rigidity, good transmission motion and guiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

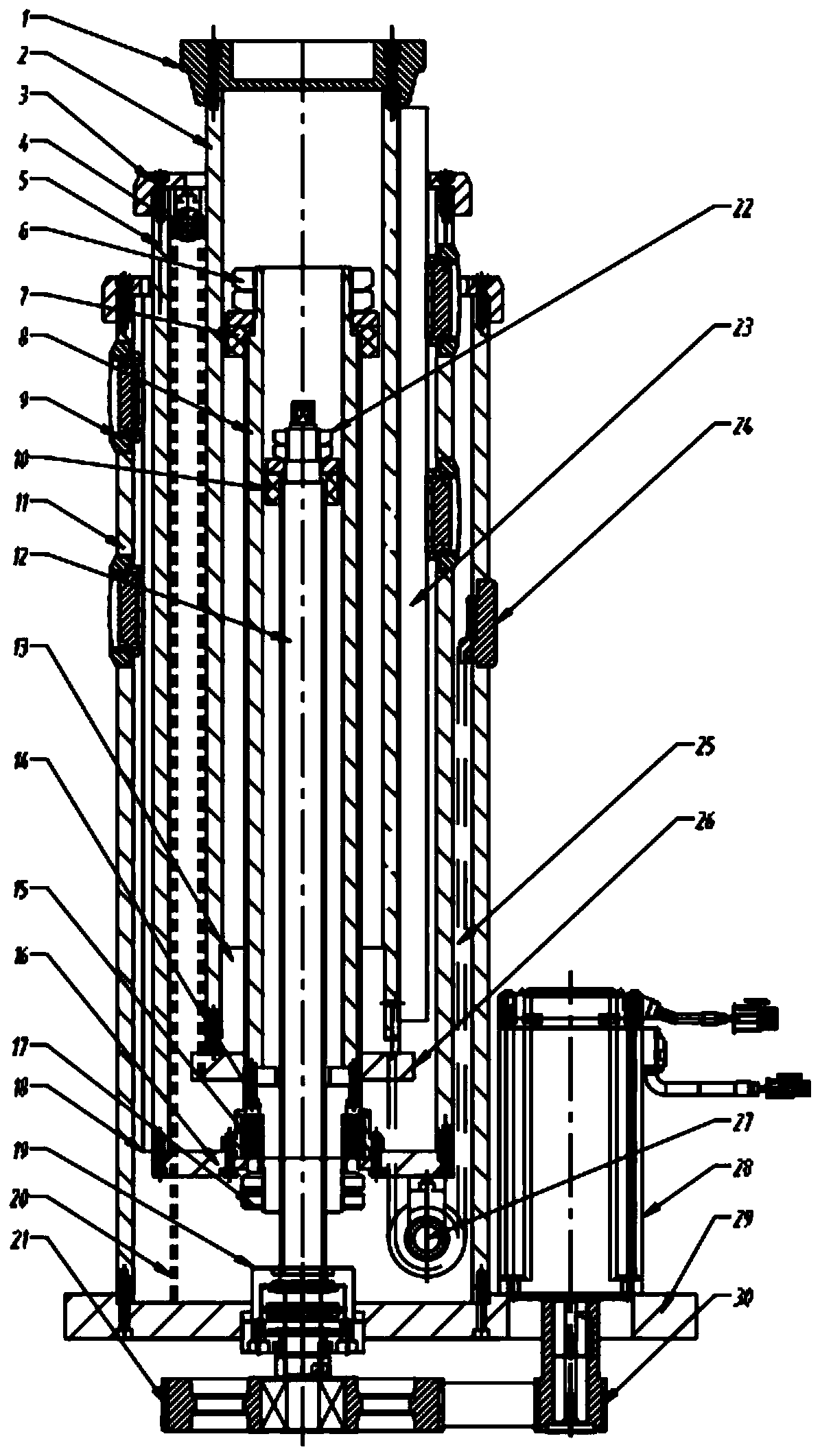

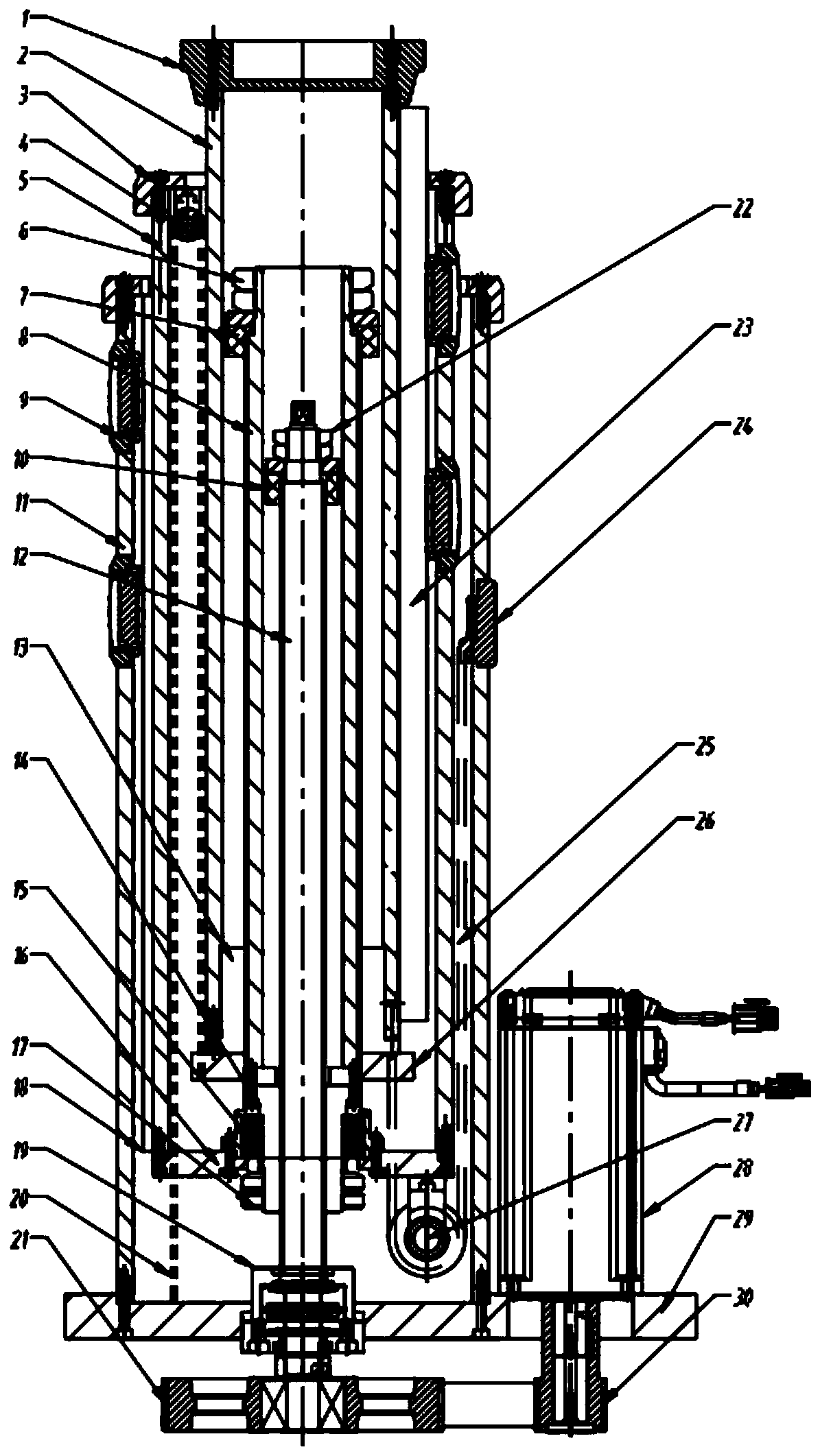

[0029] combine figure 1 , n=2 of the multi-stage synchronous lead screw push rod mechanism in the embodiment of the present invention, and the two-stage synchronous lead screw push rod mechanism is specifically:

[0030] The transmission mechanism includes a first-stage transmission device and a second-stage transmission device; the first-stage transmission device includes a servo motor 28, a motor synchronous pulley 30 arranged on the output shaft of the servo motor 28, and a ball driven by the motor synchronous pulley 30. The screw synchronous pulley 21, and the first-stage ball screw 12 coaxially arranged and connected to the ball screw synchronous pulley 21; wherein, the first-stage ball screw 12 and the ball screw synchronous pulley 21 are coaxially arranged The first-level ball screw support 19 fixed on the fixed base plate 29, the first-level ball screw 12 is arranged on the first-level ball screw support 19; The secondary hollow ball screw 8 coaxial with it; the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com