Traction electromagnet capable of precisely controlling displacement quantity

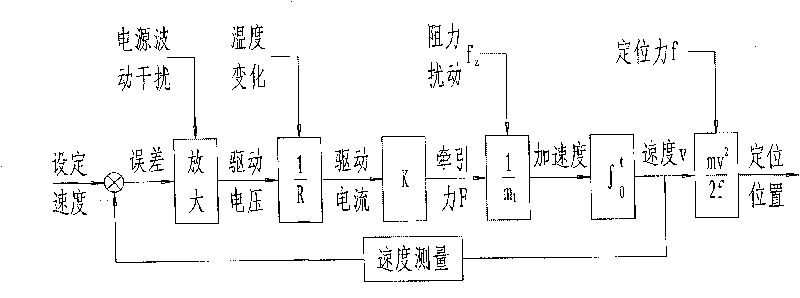

A traction electromagnet and precise control technology, applied in the traction field, can solve the problems of unstable running speed of objects, large dispersion of final positioning positions, and difficulty of electromagnets to meet positioning requirements, so as to suppress power supply fluctuations, avoid excessive impact, The effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

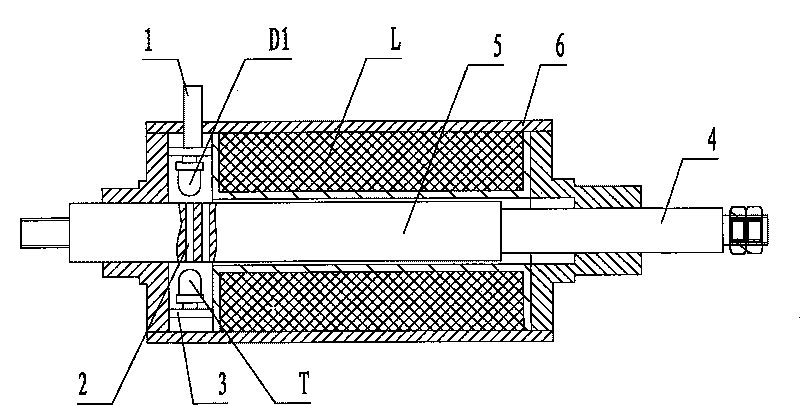

[0015] see figure 1 , the electromagnet of this device is made up of coil L, armature 5 and shell 6, and coil L generates magnetic field when electrified, and magnetic field line pulls armature 5 to do work, and armature 5 pulls object to do linear motion. The photoelectric sensor of the control circuit is fixedly connected with the casing 6 of the electromagnet through the circuit board 3 , and its luminescent tube D1 and photoelectric tube T are respectively located on both sides of the armature 5 of the electromagnet. A detection hole 2 is opened every 2mm along the axial direction on the armature. When the armature moves, the light emitted by the light-emitting tube D1 passes through each detection hole to reach the photoelectric tube in turn, and the photoelectric tube T outputs an electric pulse signal reflecting the moving speed of the armature.

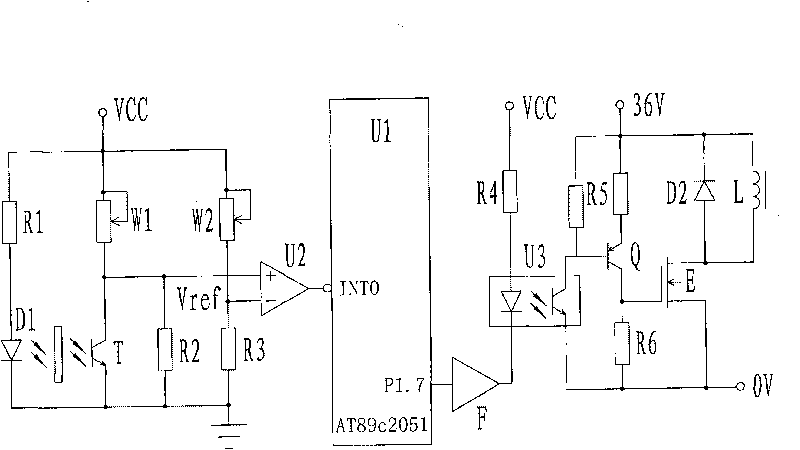

[0016] see figure 2 , The photoelectric sensor is composed of resistors R1, R2, light emitting tube D1, potentiometer W1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com