Novel real time efficiency testing table and testing method for high-low temperature non-linear mechanism

A technology of efficiency test and test method, applied in the field of machinery, can solve the problem of inability to accurately obtain the real-time efficiency of the mechanism, and achieve the effect of ensuring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

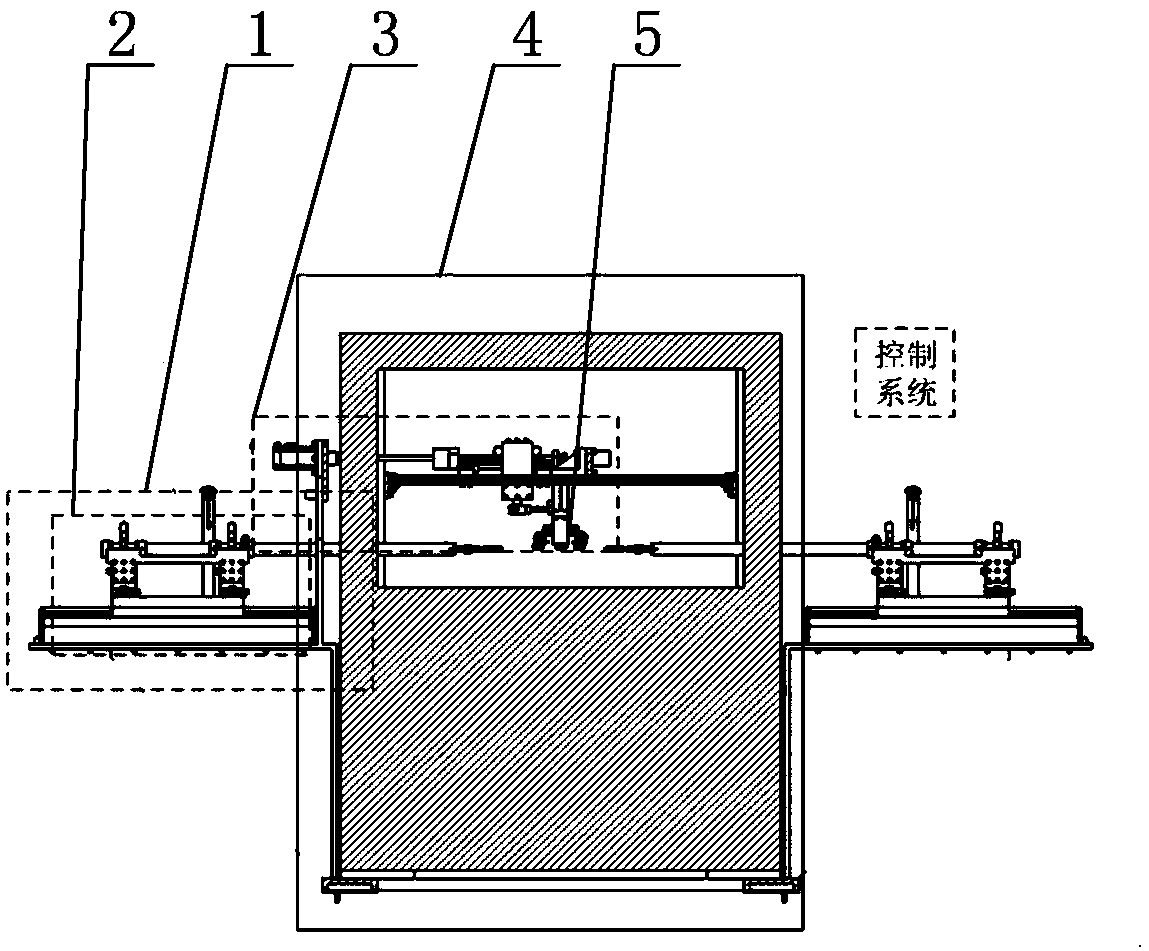

[0016] Specific implementation mode one: combine figure 1 To illustrate this embodiment, a new high-low temperature nonlinear mechanism real-time efficiency test bench includes two linear loading and measurement subsystems 1, two tolerance adjustment subsystems 2, drive and measurement subsystems 3 and The high and low temperature environment chamber 4, the tested mechanism 5 is set in the high and low temperature environment chamber 4, the drive and measurement subsystem 3 is connected with the tested mechanism 5, and the two tolerance adjustment subsystems 2 are arranged symmetrically on both sides of the tested mechanism 5 , each linear loading and measuring subsystem 1 is installed on a tolerance adjustment subsystem 2 respectively.

[0017] Tolerance adjustment subsystem 2 includes linear motor module, X-direction position adjustment platform, Y-direction displacement adjustment platform and support. Linear loading and measurement subsystem 1 is installed on Y-direction d...

specific Embodiment approach 2

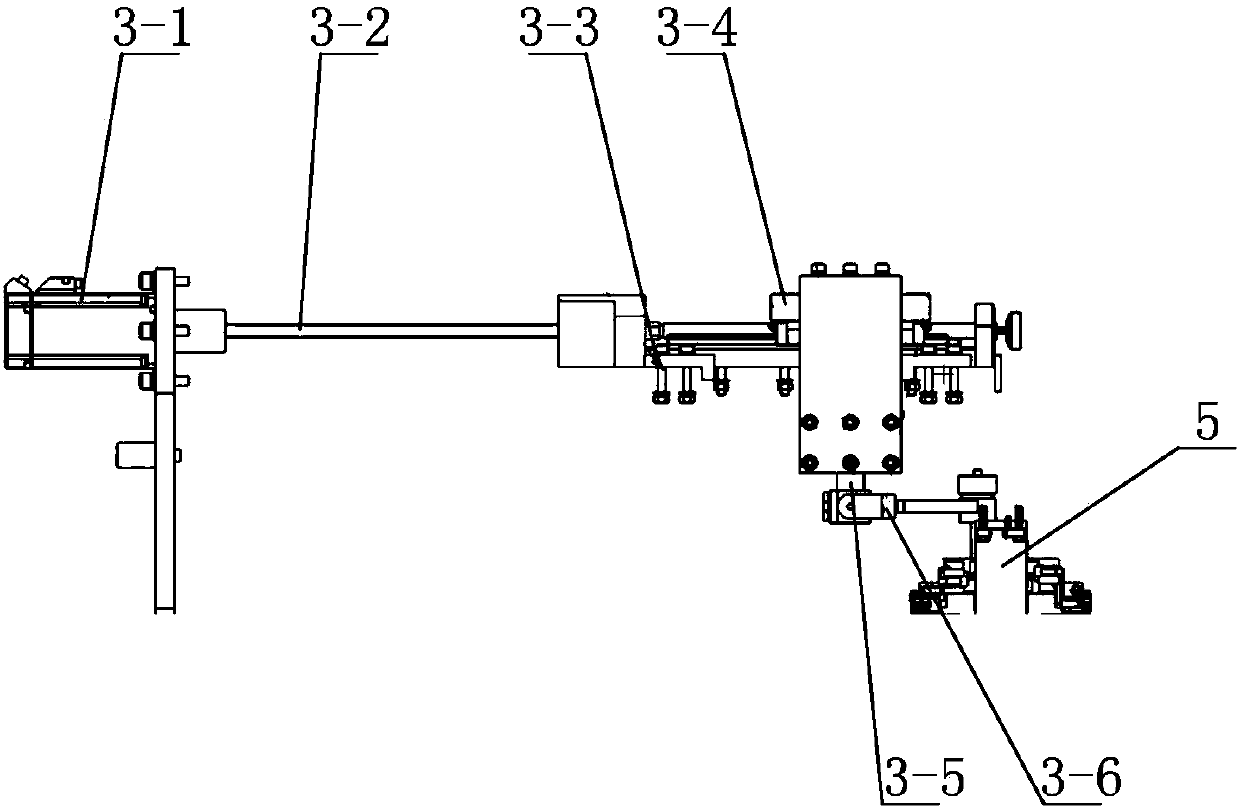

[0021] Specific implementation mode two: combination figure 2 To illustrate this embodiment, the drive and measurement subsystem 3 of a new high-low temperature nonlinear mechanism real-time efficiency test bench described in this embodiment includes a drive servo motor 3-1, a drive shaft 3-2, and a fixed partition 3-3 , linear motion unit 3-4, cantilever type tension pressure sensor 3-5 and sliding commutator 3-6, driving servo motor 3-1 is connected with fixed partition 3-3 through drive shaft 3-2, linear motion unit 3 -4 is installed on the fixed partition 3-3, the linear motion unit 3-4 is connected with the cantilever tension pressure sensor 3-5, and the lower end of the cantilever tension pressure sensor 3-5 is connected to the tested unit through the sliding commutator 3-6 Bodies 5 are connected. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

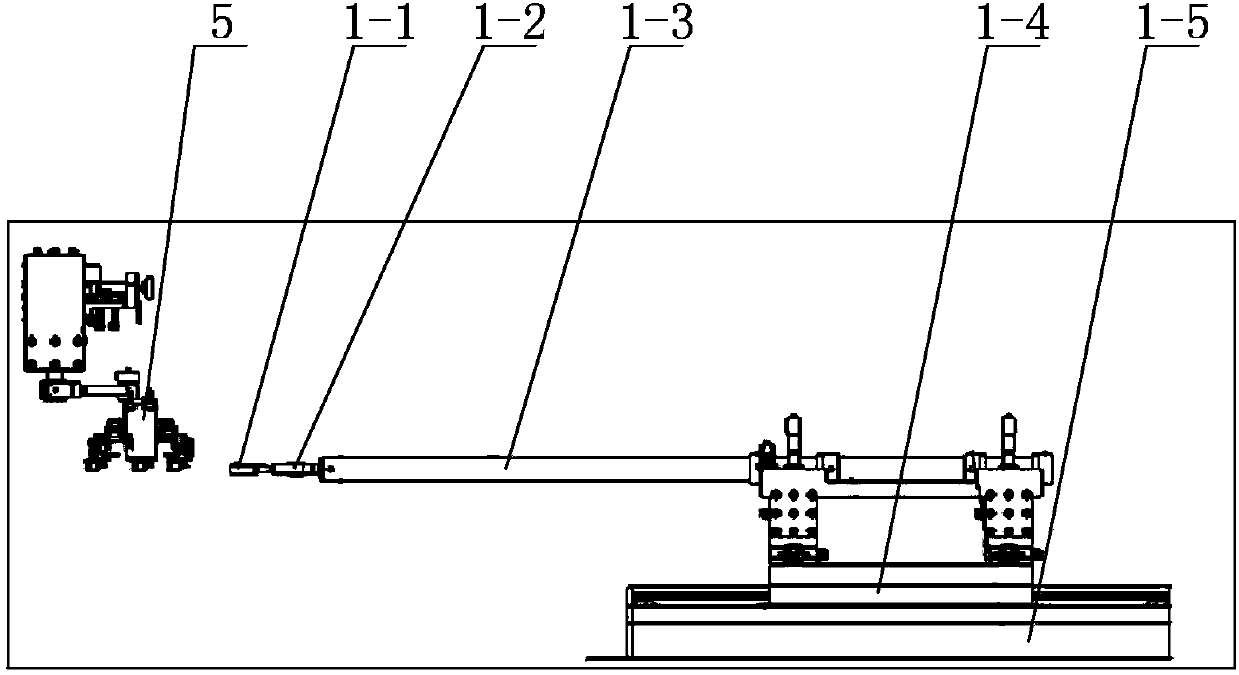

[0022] Specific implementation mode three: combination image 3 Describe this embodiment, the linear loading and measuring system 1 of a new high and low temperature nonlinear mechanism real-time efficiency test bench described in this embodiment includes a connecting piece 1-1, an S-type tension and pressure sensor 1-2, and a cantilever beam shaft 1 -3, the linear motor mover 1-4 and the linear motor stator 1-5, the linear motor mover 1-4 is installed on the linear motor stator 1-5, and the linear motor mover 1-4 can move along the linear motor stator 1-5 5 Linear movement, the cantilever beam shaft 1-3 is installed on the linear motor mover 1-4, the S-type tension pressure sensor 1-2 is installed at the end of the cantilever beam shaft 1-3, and the S-type tension pressure sensor 1-2 passes through The connecting piece 1-1 is connected with the mechanism 5 under test. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com