Drilling machine

A drilling machine and column technology, which is applied to the components of the boring machine/drilling machine, boring/drilling, and drilling/drilling equipment, etc., can solve the problems of low labor efficiency, long time consumption, and difficult to guarantee machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

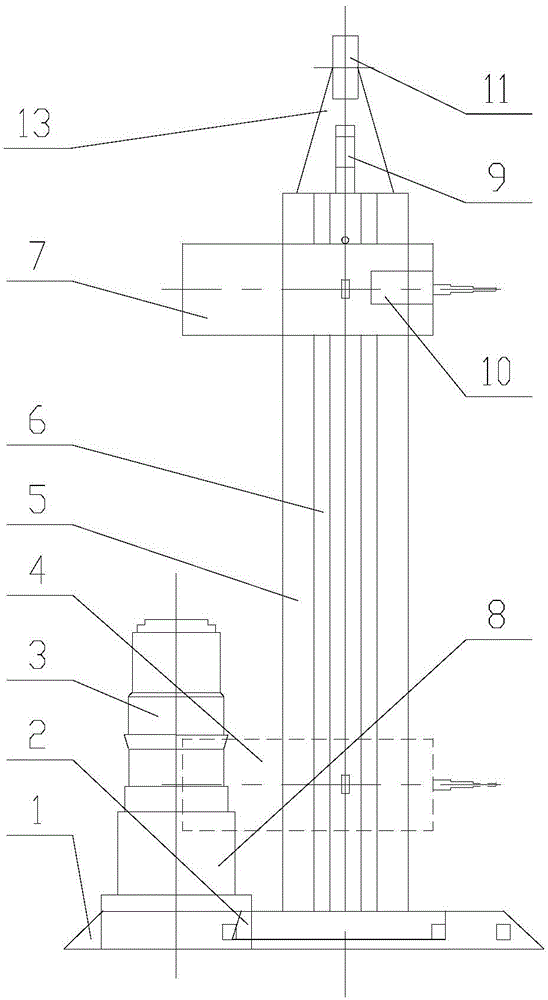

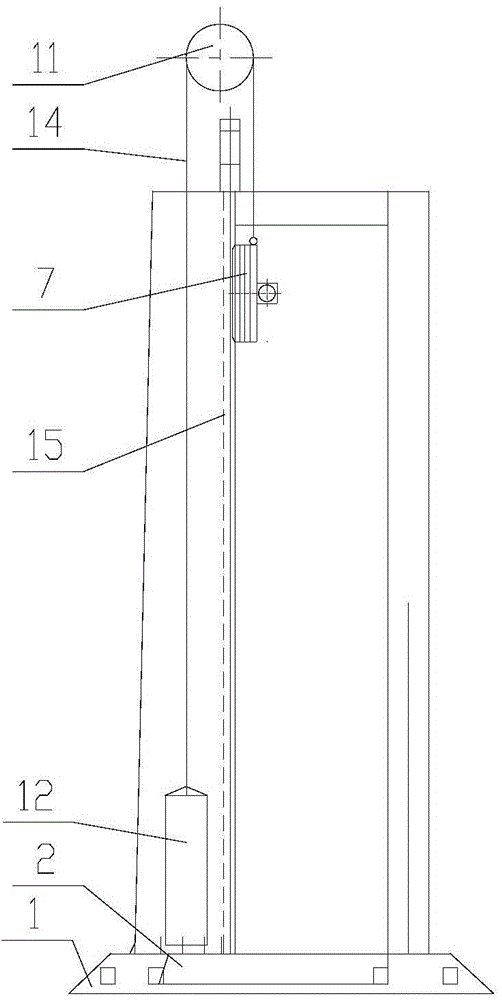

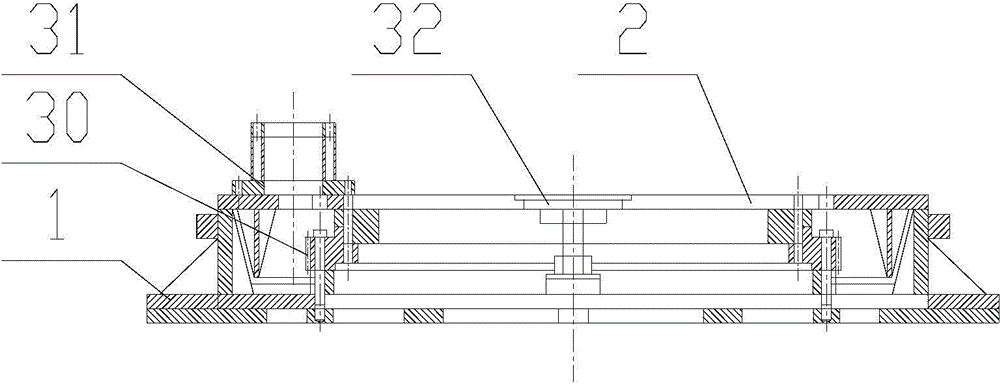

[0029] Below in conjunction with accompanying drawing, this technology is further described:

[0030] see figure 1 , figure 2 As shown, generally speaking, this kind of drilling machine includes a horizontally arranged base 1, a rotary table 2 that is parallel to the base 1 and rotated on the base 1, and a column 5 whose axis is parallel to the rotary axis of the rotary table 2 is fixedly connected to the rotary table. On the workbench 2, move the large carriage 7 arranged on the column 5 along the axial direction of the column 5 when moving, and move the small carriage 10 arranged on the large carriage 7 perpendicular to the axial direction of the column 5 when moving. Cutting device on the small carriage 10 (see also Figure 5-11 shown); the cutting device includes a cutting motor 19, a hydraulic power head 20 connected with the cutting motor 19 through a reduction gear 20, and the feeding amount of the hydraulic power head 20 along the vertical and intersecting direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com