Mold release machine

A technology of demolding machine and demoulding device, applied in the field of demolding machine, can solve the problems of large application, difficult demoulding, inner wall damage of tubular products, etc., and achieve accurate moving position and speed, high precision, and improve control efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

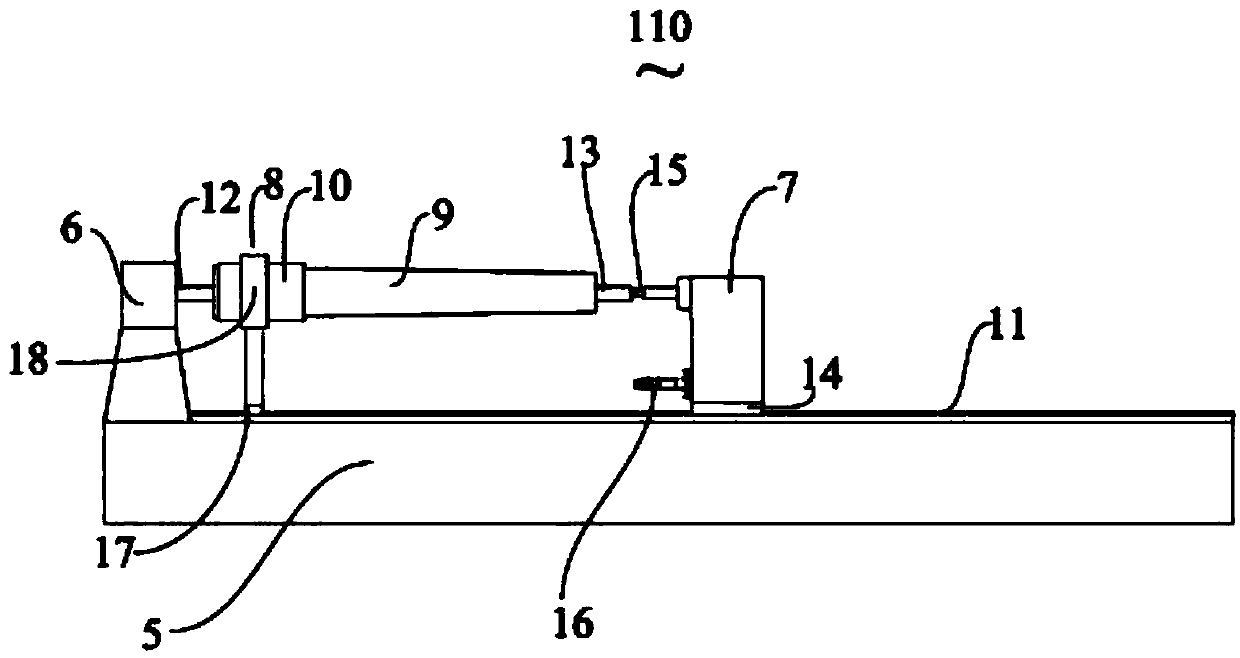

[0023] Such as image 3 As shown, in this embodiment, the demoulding machine 110 includes a frame 5, a main fixing device 6, an auxiliary fixing device 7, a moving demoulding device 8 and a driving device (not shown). The main fixing device 6 , the auxiliary fixing device 7 and the mobile stripping device 8 are all arranged on the frame 5 . In this embodiment, the driving device is a motor, and the motor is used to drive the mobile demoulding device 8 to move. Such as Figure 4 As shown, the product to be demolded is the coiled tube 10 positioned on the mandrel 9 .

[0024] Wherein, the frame 5 is an elongated frame structure, and its material may be metal such as iron or steel. A slide rail 11 is arranged on the frame 5 , and the auxiliary fixing device 7 and the mobile demoulding device 8 can both move on the slide rail 11 .

[0025] Wherein, the bottom of the main fixing device 6 is fixed on one end of the frame 5 , and the main fixing device 6 is used for fixing the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com