Tank entering and exiting system and method

A trough system and a trough-in technology, which is applied in the direction of photographic technology, equipment, photographic auxiliary technology, etc., can solve the problems of high energy consumption, low equipment efficiency, and long empty time of the electrolytic cell, so as to achieve a high degree of environmental protection and save purchases Expenses for spare plates and short empty slot time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

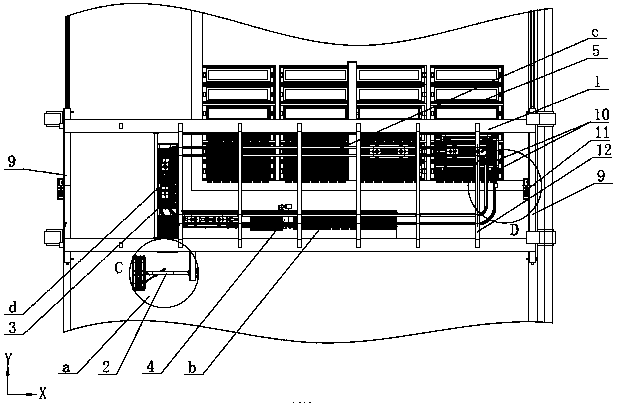

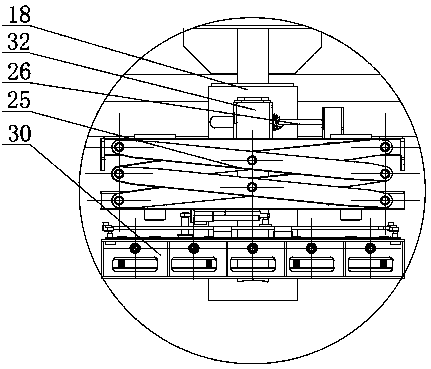

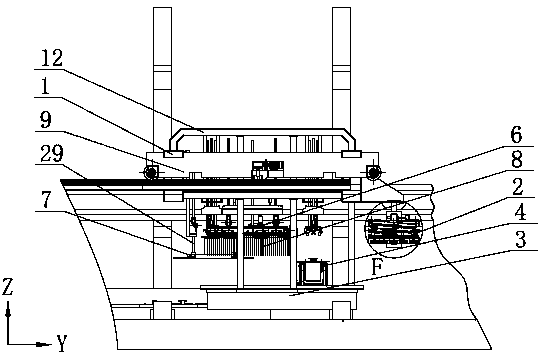

[0047] For the convenience of explanation, in figure 1 , figure 2 , image 3 The XYZ Cartesian coordinate system is marked in , the X-axis direction is the length direction of the main beam 1 of the cart, the Z-axis is the vertical axis, and the X-axis, Y-axis, and Z-axis directions are orthogonal to each other.

[0048] Such as figure 2 As mentioned above, the slot system of the present invention arranges four working areas in a ring, which are the feeding and discharging area a, the waiting area b, the working area c of the slot and the passivation area d along the counterclockwise direction. The middle annular track 10 is roughly in the shape of a rounded rectangle, wherein the area b to be entered and the working area c to enter and exit the tank are respectively located on the two long sides of the rectangle, most of the two long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com