Double-cutter asphalt concrete test piece cutting machine

A kind of asphalt concrete and cutting machine technology, applied in the direction of working accessories, stone processing tools, manufacturing tools, etc., can solve the problems of low safety factor, small size range of asphalt concrete samples, low work efficiency, etc., to reduce cutting size errors, reduce The effect of human participation and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

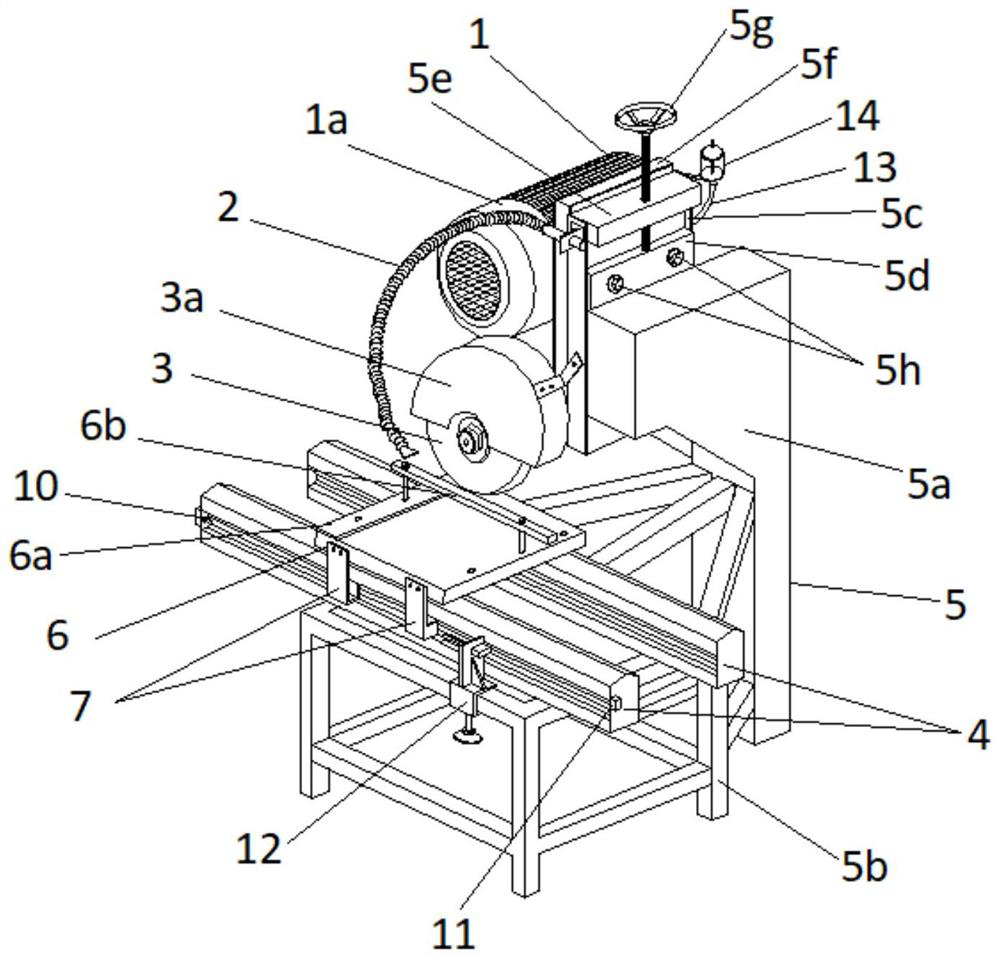

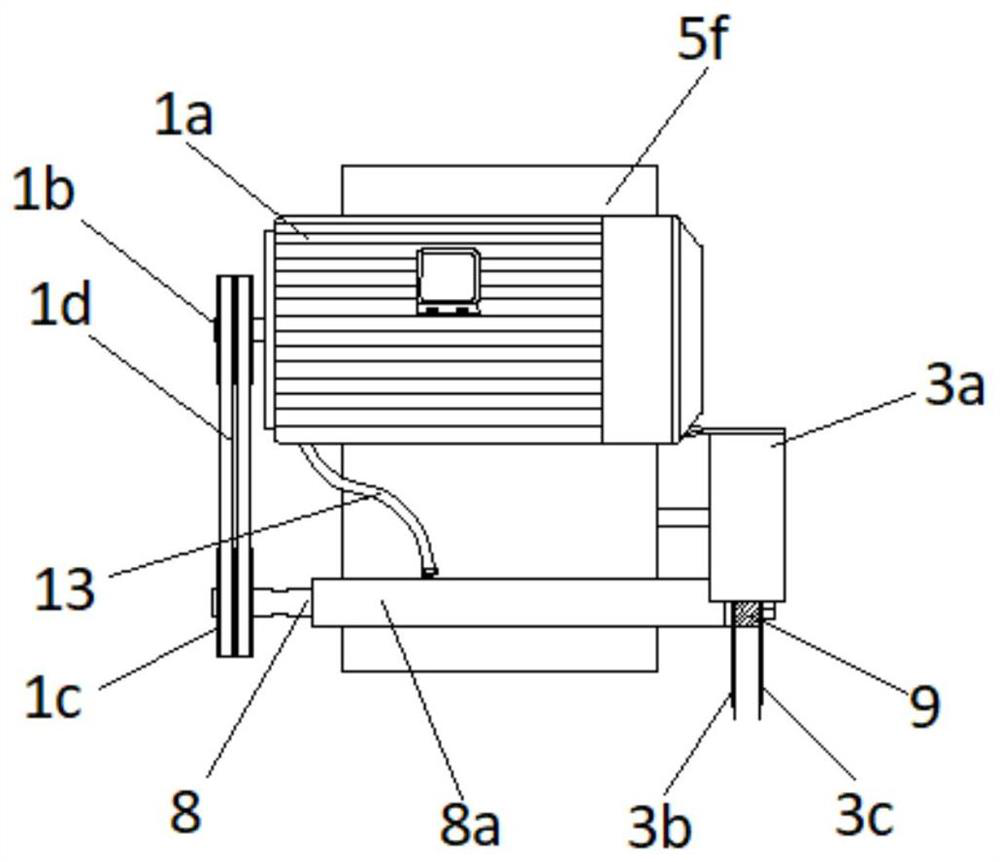

[0102] Such as figure 1 Shown, the structure of a kind of double-cutter asphalt concrete specimen cutting machine of the present invention comprises: support system 5, cutting system and control system;

[0103] The support system 5 is provided with a height-adjustable cutting system, and the cutting system is used for cutting asphalt concrete specimens; the support system 5 is also provided with a horizontally movable sample delivery system, and the sample delivery system is located at Below the cutting system, it is used to push the asphalt concrete sample to be cut for the cutting system;

[0104] The control system is used to control the start or stop of the cutting work of the cutting system, and is used to control the movement or stop of the position of the sample feeding system.

[0105] In this embodiment, by setting the cutting system as a height-adjustable structure, it is convenient to adjust the height of the cutting system according to the thickness of the asphal...

Embodiment 2

[0137] The difference between embodiment 2 and embodiment 1 is:

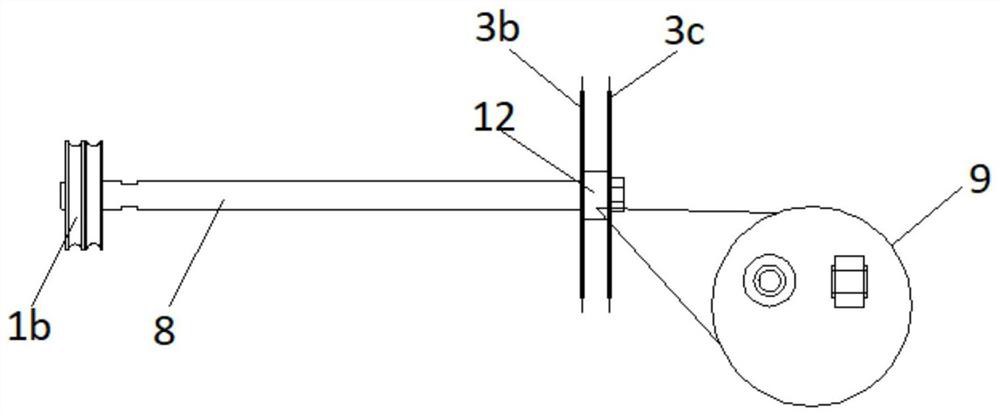

[0138] Such as Figure 9 , Figure 10 , Figure 11 and Figure 12 As shown, the composite transmission shaft 8 includes: an inner transmission shaft 8e and an outer transmission shaft 8f, both of which are hollow shafts, and the inner transmission shaft 8e passes through the outer transmission shaft shaft 8f; the two ends of the inner transmission shaft 8e stretch out the outer transmission shaft 8f respectively; both ends of the inner transmission shaft 8e are provided with threads, and one end of the inner transmission shaft 8e is provided with the first The cutter head 3b, the second cutter head 3c; the end of the outer drive shaft 8f far away from the first cutter head 3b, the second cutter head 3c is connected to the second drive wheel 1c by transmission;

[0139] The middle section of the outer surface of the inner transmission shaft 8e is provided with a spline 8eb, and the middle section of the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com