Three-dimensional printer and printing method thereof

A 3D printer and print head technology, applied in the field of printing, can solve problems affecting 3D entity printing, touch or mutual interference, and 3D entity damage, and achieve the effects of preventing damage, improving driving accuracy, and improving printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

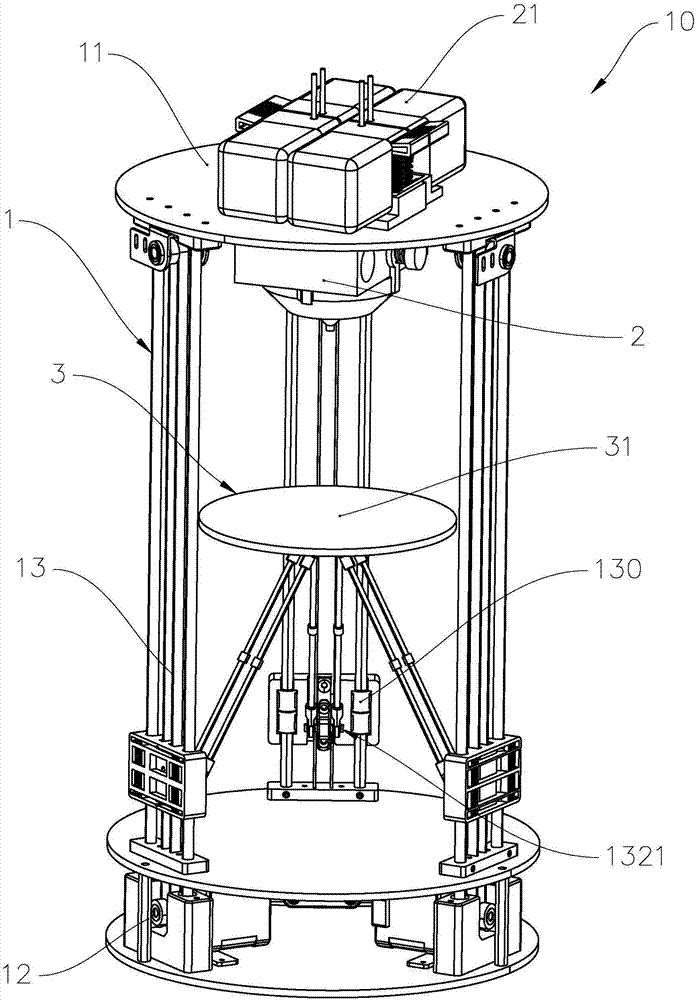

[0036] refer to figure 1 , the three-dimensional printer 10 includes a frame 1, a first printing head 2 and a printing platform 3, the first printing head 2 is used to heat the molding material to make the molding material in a molten state, and then spray the molten molding material to the printing platform 3 to form a three-dimensional entity.

[0037] refer to Figure 2 to Figure 4 , and combined with figure 1, The frame 1 includes an upper support base 11 , a lower support base 12 and three sets of driving devices 13 . Three groups of driving devices 13 are evenly arranged between the upper supporting base 11 and the lower supporting base 12 along the circumferential direction of the upper supporting base 11, and the printing platform 3 is located at the upper supporting base 11, the lower supporting base 12 and the three groups of driving devices 13. within the space.

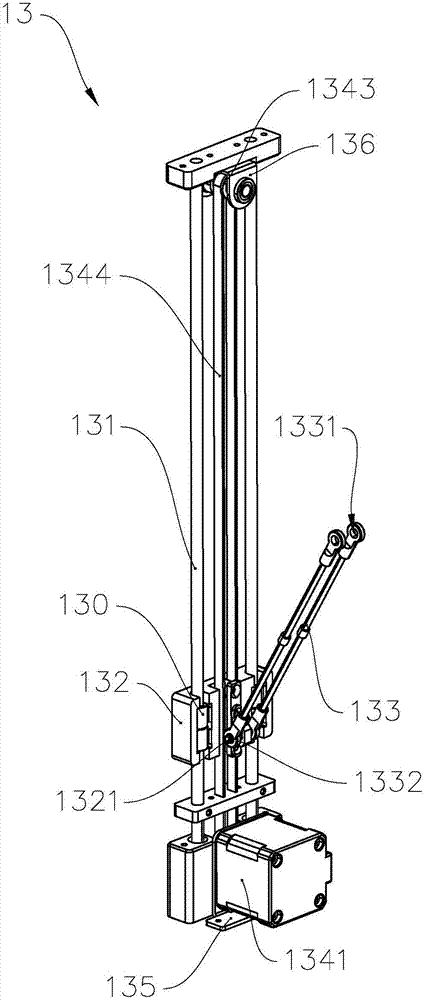

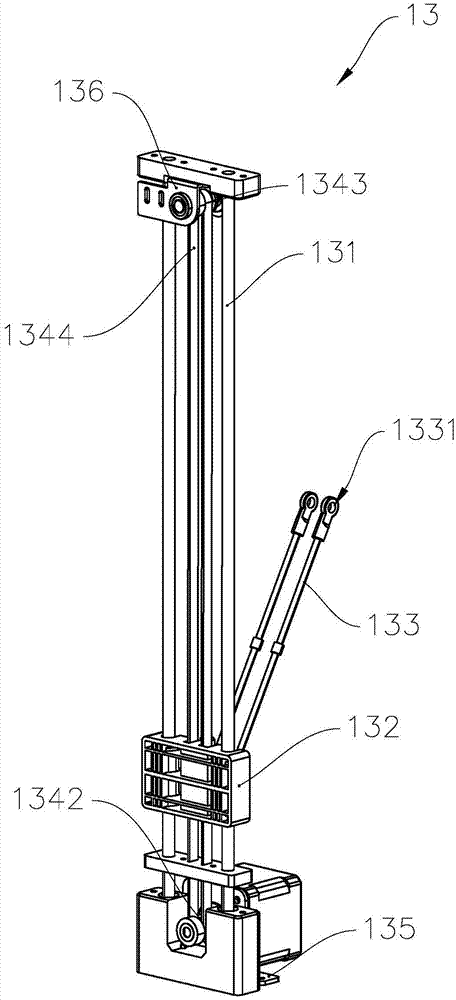

[0038] Specifically, each group of driving devices 13 includes a guide rail 131, a connection block...

no. 2 example

[0049] Applying the inventive concept of the first embodiment of the three-dimensional printer, the difference between the second embodiment of the three-dimensional printer and the first embodiment is that the first print head 4 of the second embodiment includes a powder storage bin 41, a second nozzle 42 and a powder filling port 43, Wherein, the powder storage bin 41 is used for loading molding materials, and the molding materials are mainly powdery molding materials, and the inside of the powder storage bin 41 is provided with a screw 411 that can rotate, and the screw 411 rotates under the control of the control system, so that the powder in the powder storage bin 41 The powdery molding material is delivered to the second nozzle 42, and the second nozzle 42 is used to spray the powdery molding material to the printing platform. Wherein, the second nozzle 42 is located at the downstream end of the powder storage bin 41 , and the powder loading port 43 is located at the upst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com