Labeling machine

A labeling machine and labeling technology, applied in labeling machines, labels, packaging, etc., can solve problems such as inaccurate conveying, no consideration of backing paper recycling, and inability to accurately control the precise operation of label paper, so as to improve operating accuracy and avoid The effect of inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

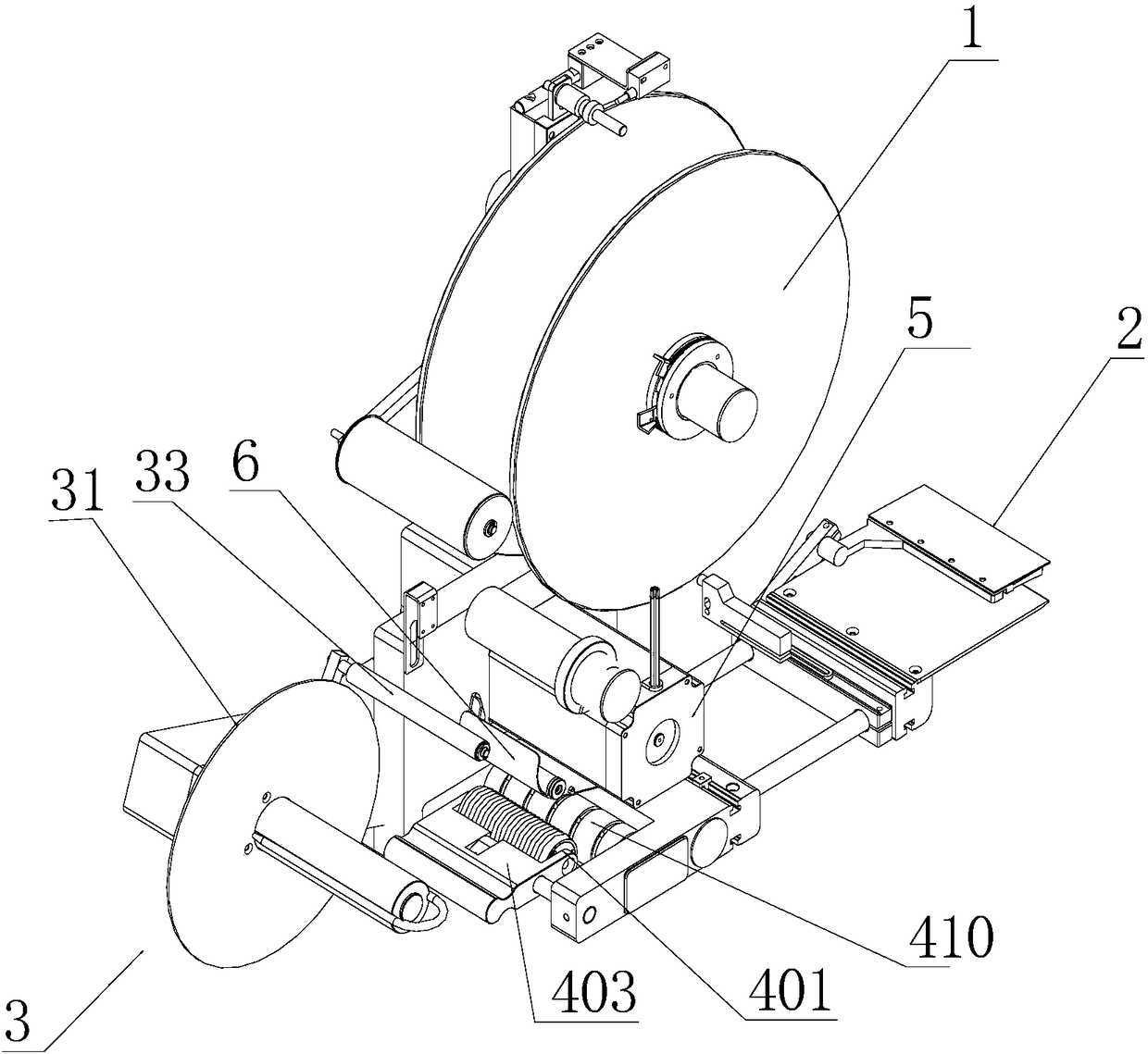

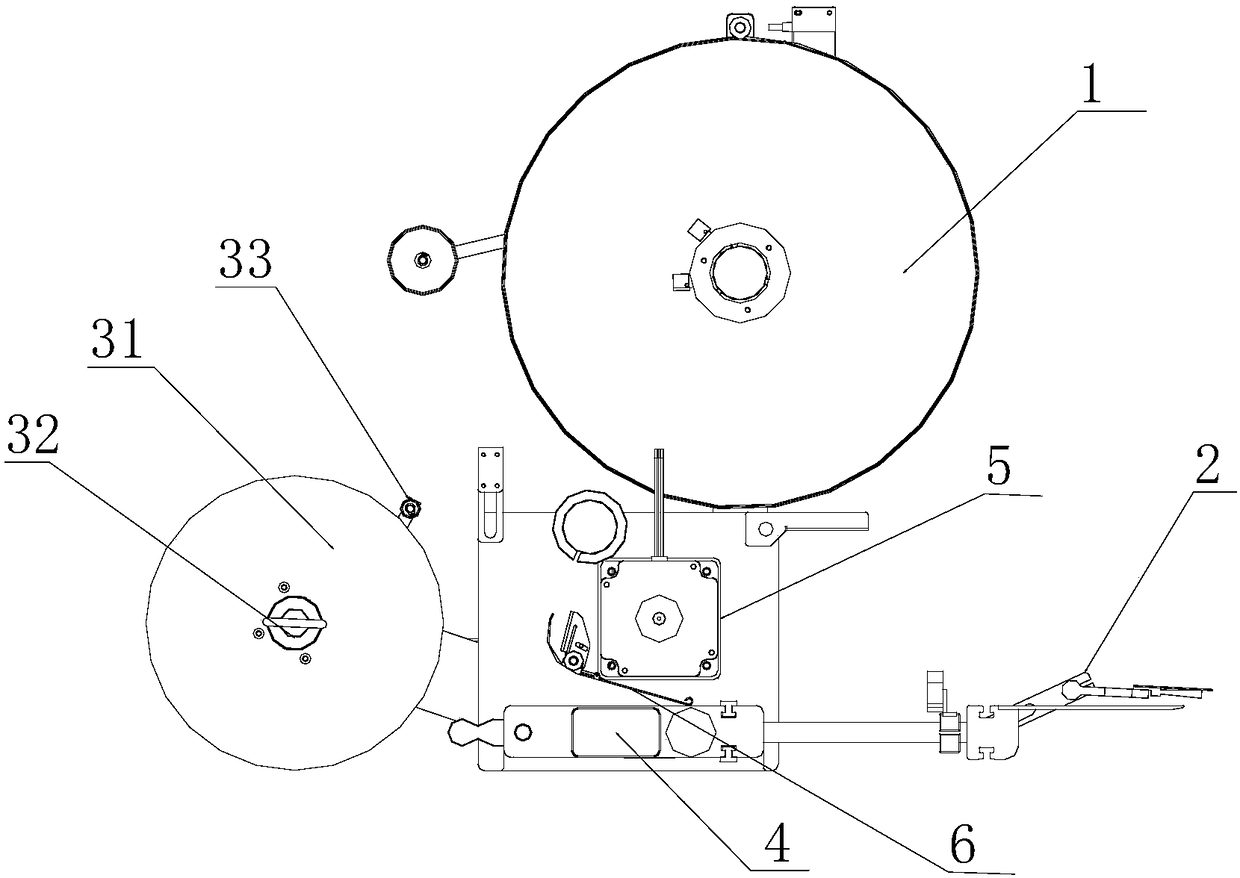

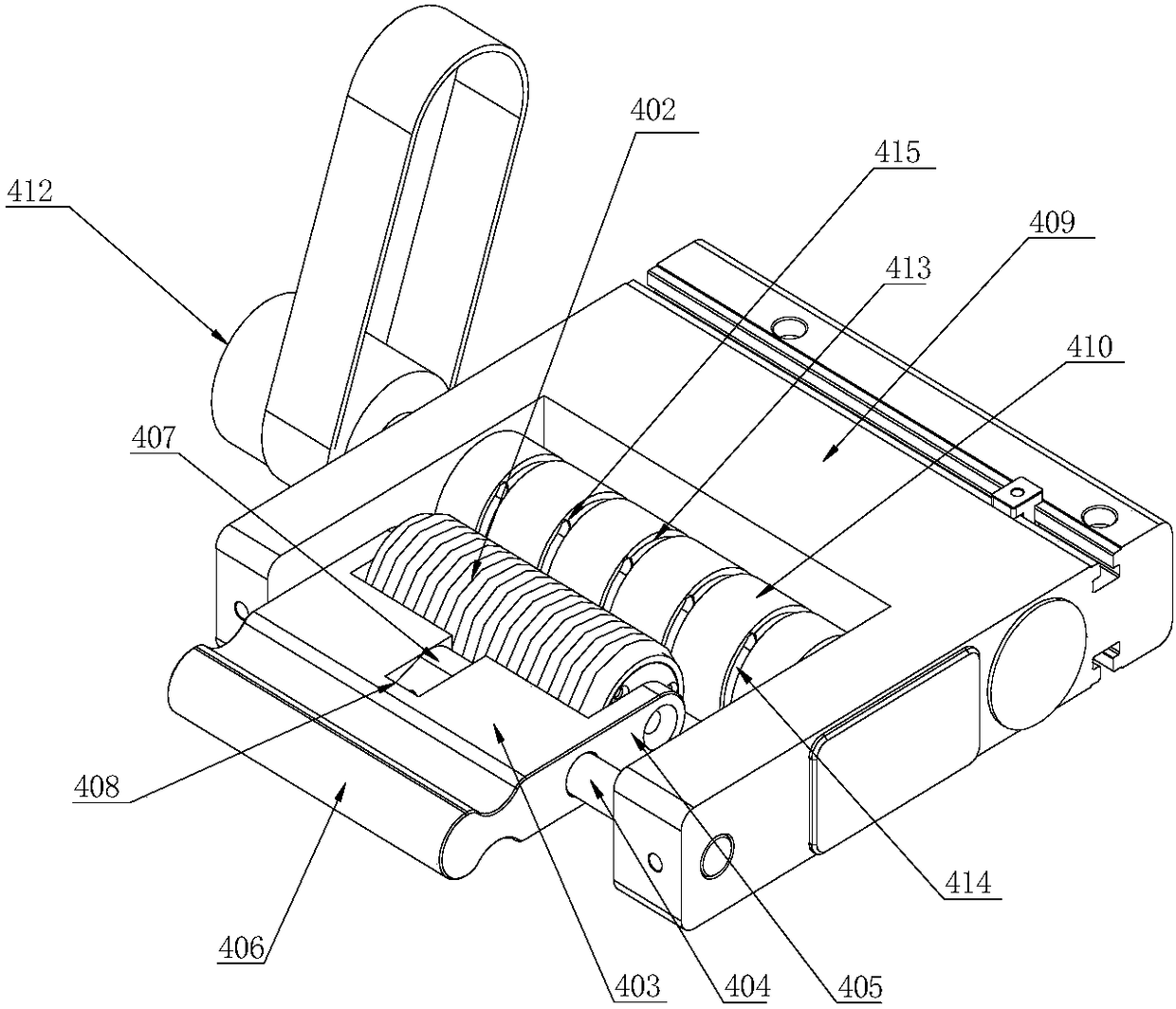

[0040] see Figure 1-6 , a labeling machine, including an unwinder 1 for outputting label paper, a label peeling assembly 2 for peeling labels from the label paper, and a backing paper winder 3 for collecting backing paper arranged in sequence, It also includes a bottom paper drive assembly 4 arranged between the label peeling assembly 2 and the bottom paper winder 3 for driving the bottom paper movement; the bottom paper drive assembly 4 is driven by a drive mechanism 5 .

[0041] In this embodiment, the power for driving the label paper to run is mainly concentrated on the backing paper driving assembly 4, which has the advantage of being driven by the backing paper driving assembly 4, avoiding the traditional driving method before the label is peeled off or driven by the winder. The way to realize the inaccuracy of label paper operation. In this solution, the bottom paper driving assembly 4 is used as the rear drive, which can effectively improve the running accuracy of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com