Precision charger for material nano metric bending mechanical properties test

A nano-scale, loading device technology, applied in the direction of using a stable bending force to test the strength of materials, can solve the problems of the complex structure of the detection device, the inability to detect the detection accuracy, and the high cost, to improve the driving accuracy and resolution, and low cost. , high-efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific content of the present invention will be further described below in conjunction with the embodiments shown in the drawings.

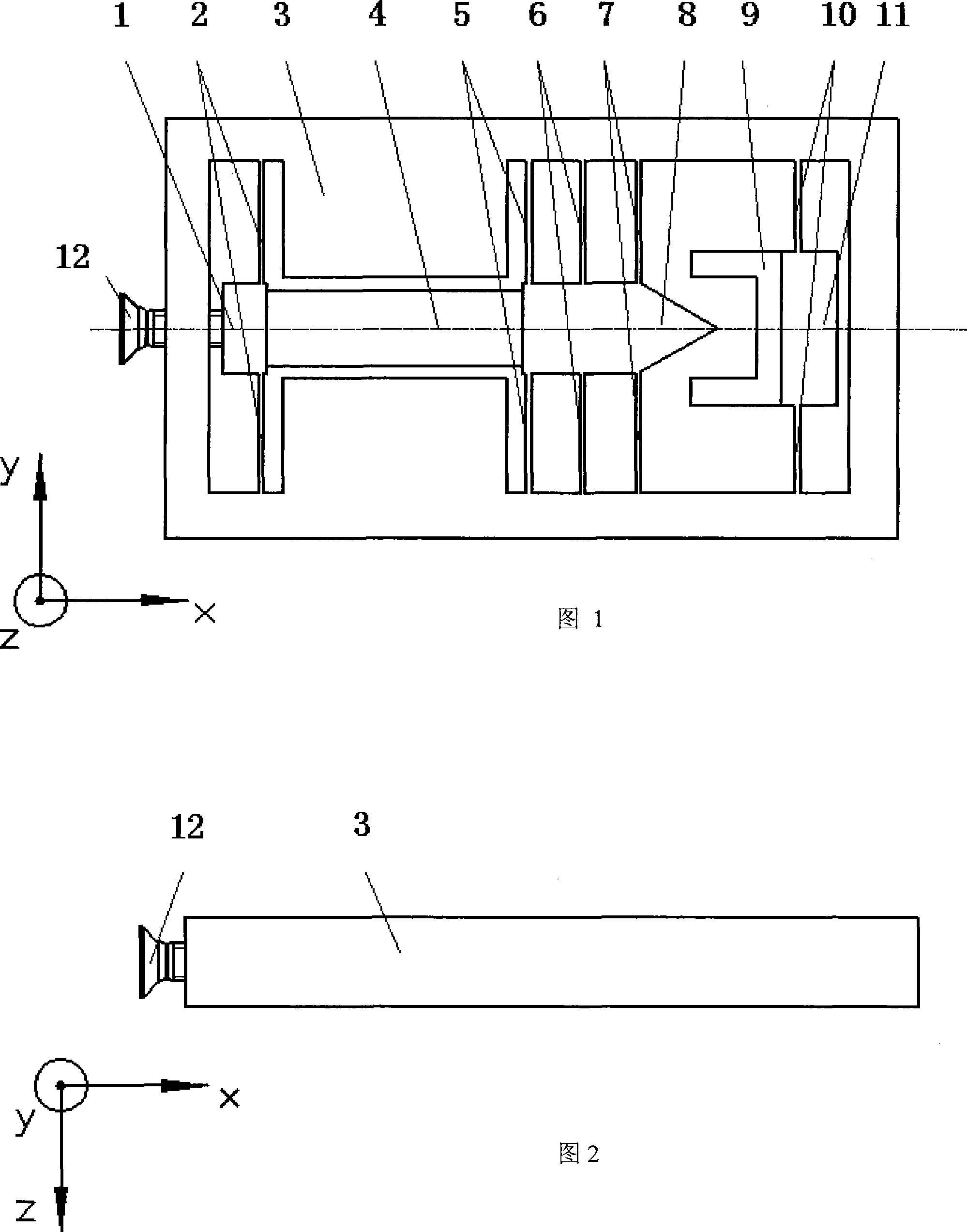

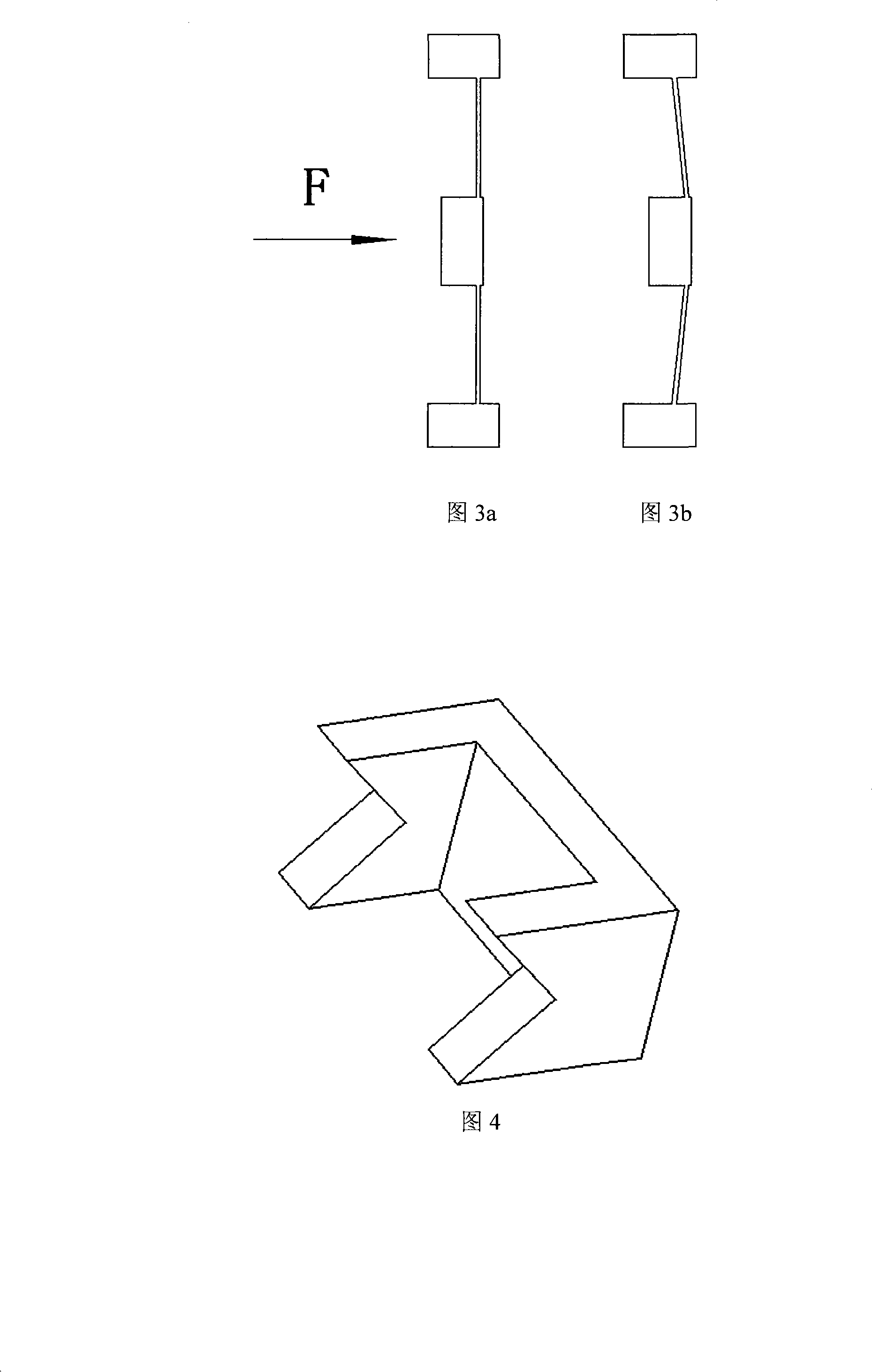

[0020] Refer to Figures 1, 2, 3, and 4, the precision loading device in the bending mechanical performance test of nanomaterials consists of a base 3, an indenter 8, a driving element 4, a stage 9 and a screw 12, etc. The indenter 8 is composed of multiple The thin-walled flexible hinges 5, 6, 7 are connected to the rigid base 3; one end of the base 3 is connected with a pre-tightening mechanism composed of a rigid body 1 and a flexible hinge 2 to pre-tighten the piezoelectric stack; The other end of the base 3 is connected with a displacement test mechanism 10, 11 composed of a flexible hinge 10 and another rigid body 11; the driving element 4 is a piezoelectric stack, and the piezoelectric stack is installed on the indenter 8 and the pre-tensioning mechanism In between, the piezoelectric stack is pre-tightened by screws 12; the stage 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com