Material nanometer dynamic performance test two freedom degree loading unit

A loading device and degree-of-freedom technology, which is used in measuring devices, analyzing materials, and testing the strength of materials by applying stable tension/pressure. problem, to achieve the effect of low cost, improved driving accuracy and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

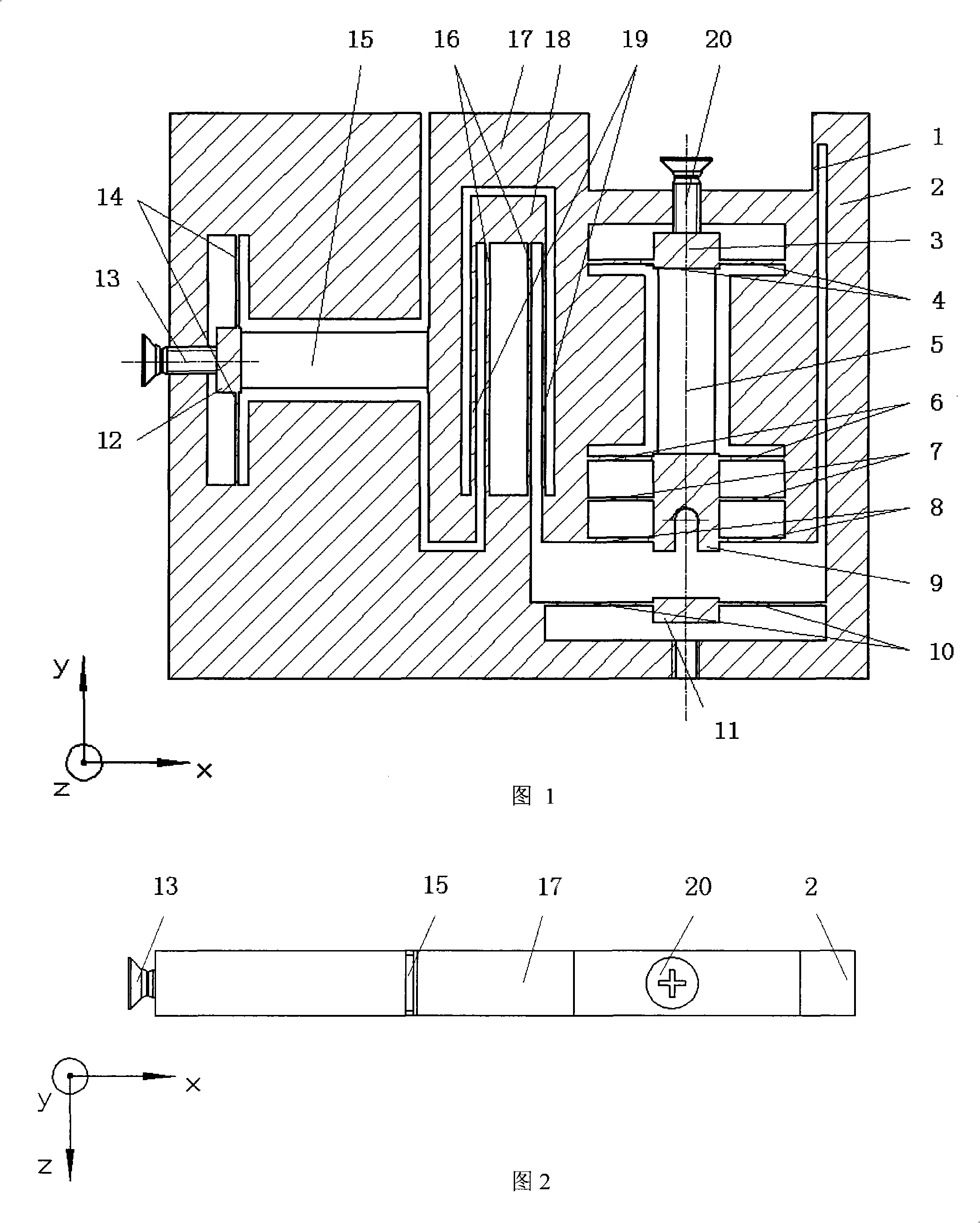

[0018] Referring to Figures 1 and 2, the indenter 9 is connected to the x-axis movement mechanism 17 by a plurality of thin-walled flexible hinges 6, 7, 8; the said x-axis positive movement mechanism 17 has a plurality of thin-walled flexible hinges 16, 19 is connected to the rigid base 2; said driving element is composed of a piezoelectric stack, wherein the piezoelectric stack 5 is integrally installed between the x-axis pretension mechanism 12, 13, 14 and the x-axis movement mechanism 17 Between, wherein the piezoelectric stack 15 is integrally installed between the indenter 9 and the indenter pretension mechanism 3, 4, 20; said x-axis pretension mechanism 12, 13, 14 consists of a rigid body 12, a screw 13 and flexible hinge 14;

[0019] The specific working process is as follows:

[0020] In the initial state, the piezoelectric stacks are not charged, and the system is in a free state. By adjusting the pretension mechanism, the position of the indenter 9 in the x and y di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com