A spatial radial unlocking mechanism driven by a shape memory alloy SMA tow

A memory alloy wire and memory alloy technology are applied in motor vehicles, space navigation equipment, space navigation aircraft and other directions, which can solve the problems of difficulty in guaranteeing the ball movement accuracy, short unlocking time and high driving precision, and achieve short unlocking time, The effect of large driving displacement and high driving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

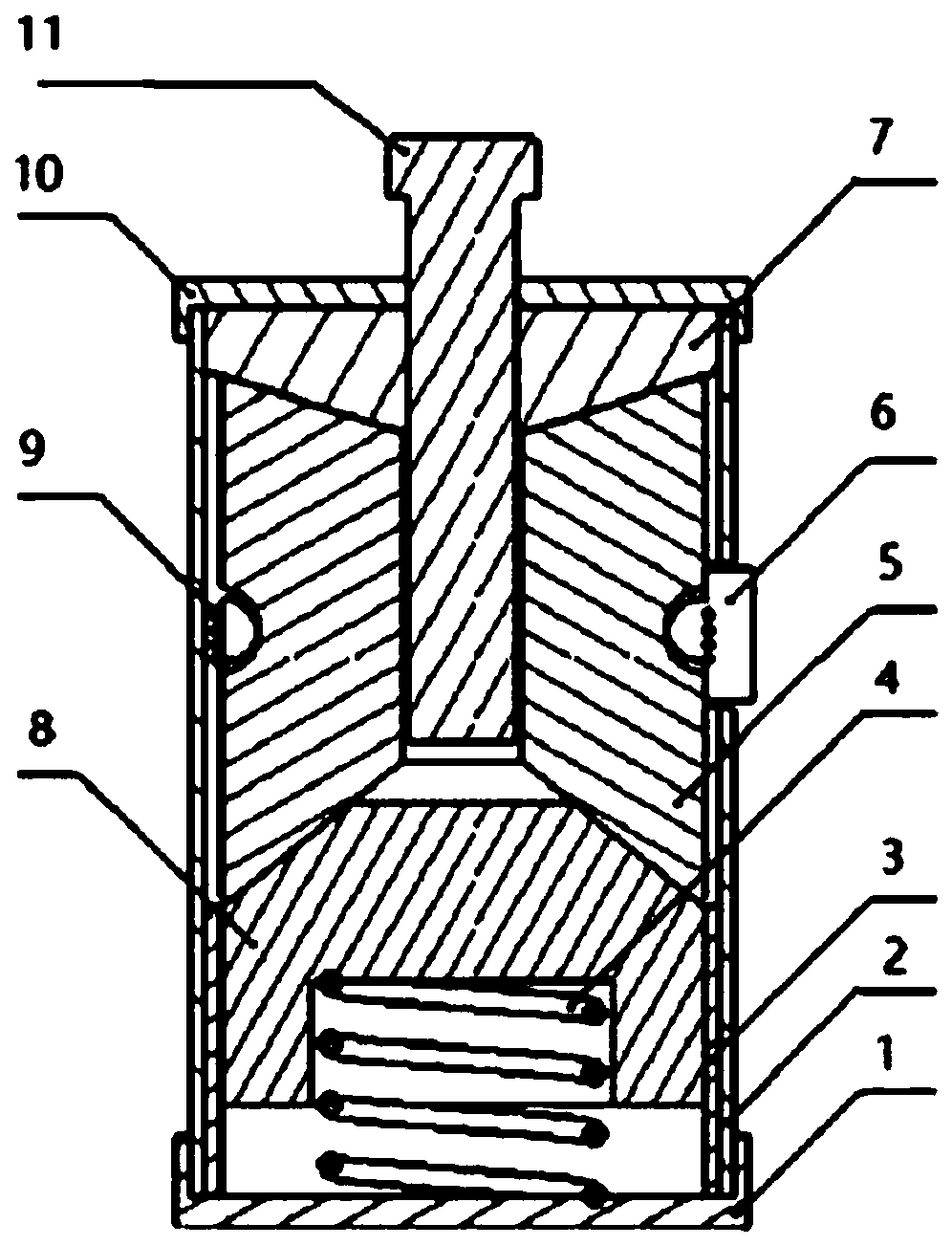

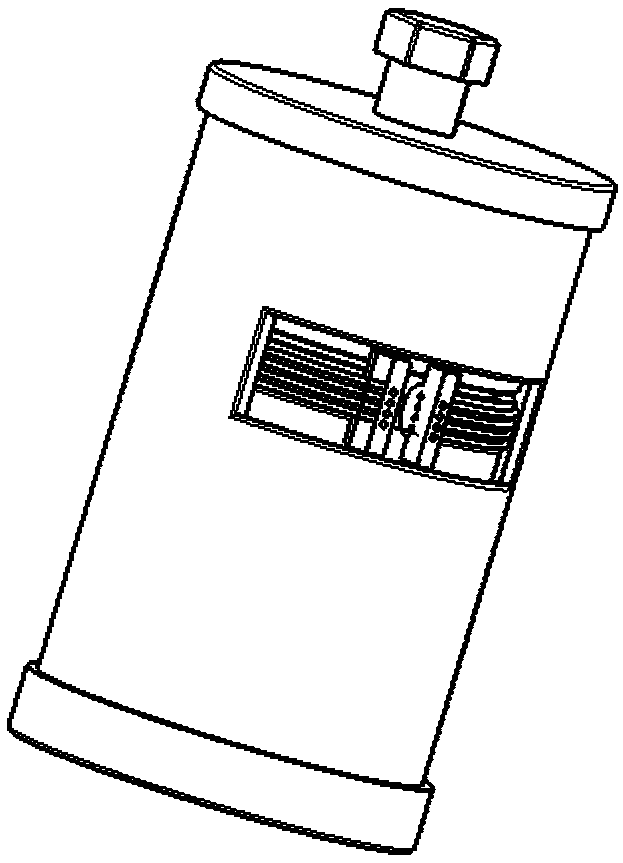

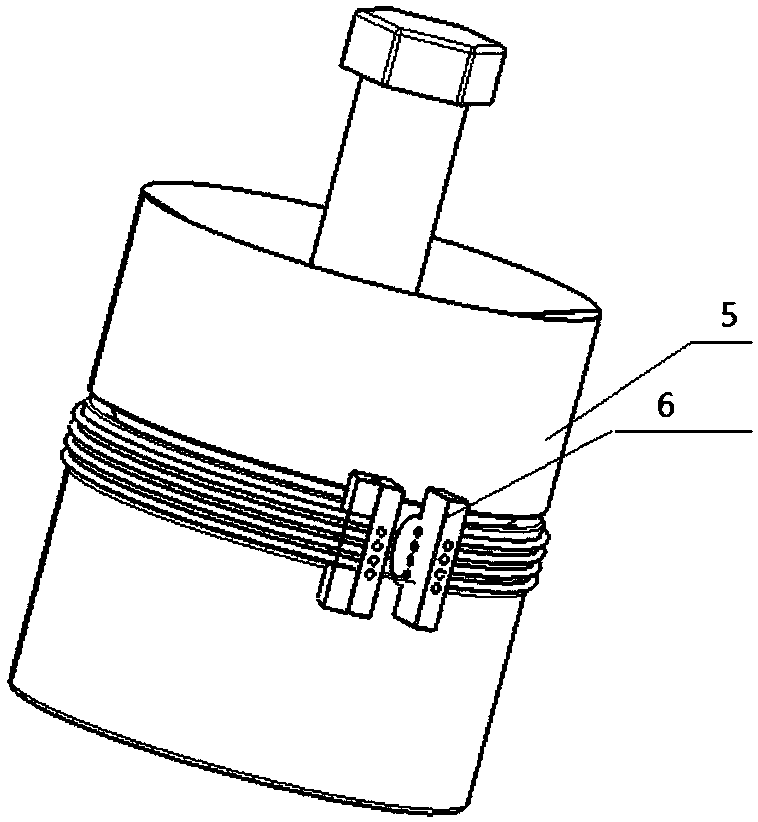

[0019] Specific implementation mode one, see Figure 1-Figure 3 Describe this embodiment. The spatial radial unlocking mechanism driven by SMA tow in this embodiment includes a base 1, an outer cover 2, a bushing 3, a compression spring 4, two split nuts 5, a rigid clamp, and a fixing frame 6. Positioning block 7, top block 8, SMA shape memory alloy wire bundle, upper cover 10 and bolt 11; the outer cover 2 is in the shape of a cylinder, the side wall of the outer cover 2 is provided with an opening, and the fixing frame 6 Set at the opening of the outer cover 2, the outer cover 2 is lined with a bushing 3, the bottom of the outer cover 2 is fixed with a base 1, the top of the outer cover 2 is equipped with an upper cover 10, and the center of the upper cover 10 A through hole is provided, the compression spring 4 is fixed on the base 1, the top block 8 is fixed above the compression spring 4, the bolt 11 is inserted from the through hole of the upper cover 10 and is located a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com