Direct-driven redundant planar parallel mechanism control device and redundant planar parallel mechanism control method

A control device, parallel technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of reducer energy loss, influence of mechanism transmission accuracy, etc., and achieve the effect of reducing mass, simplifying structure, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

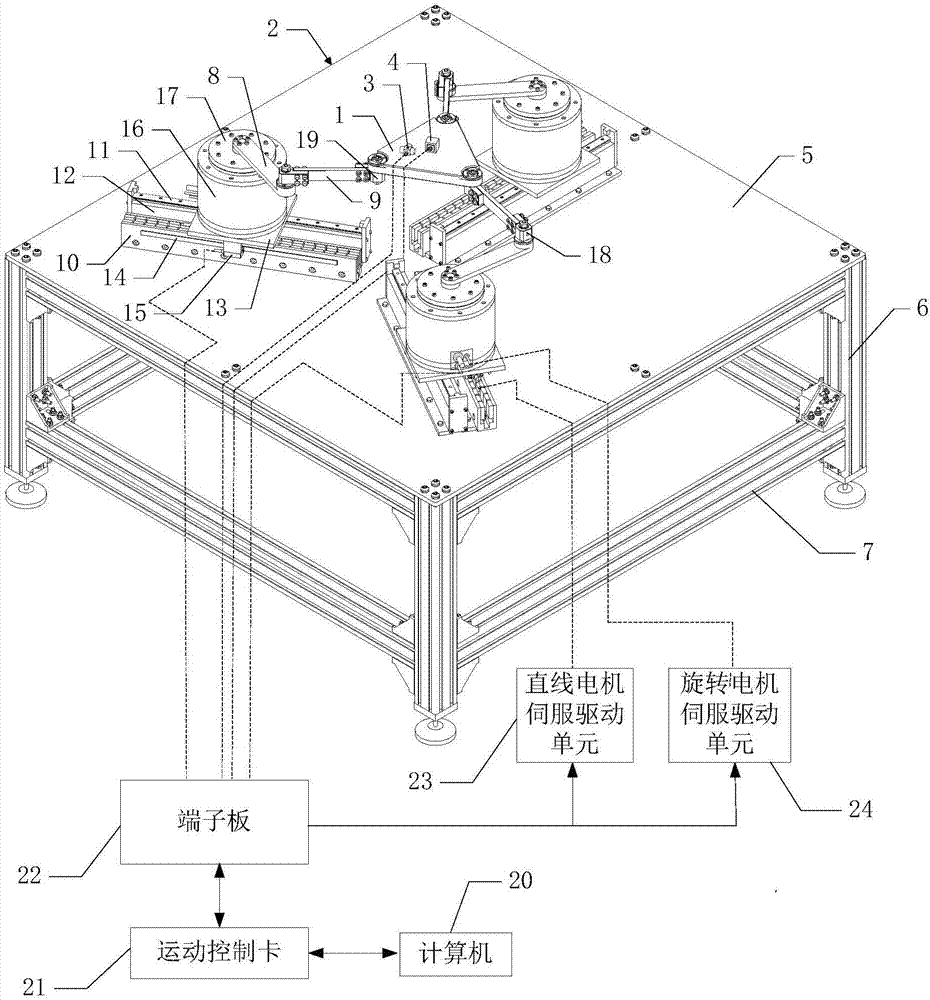

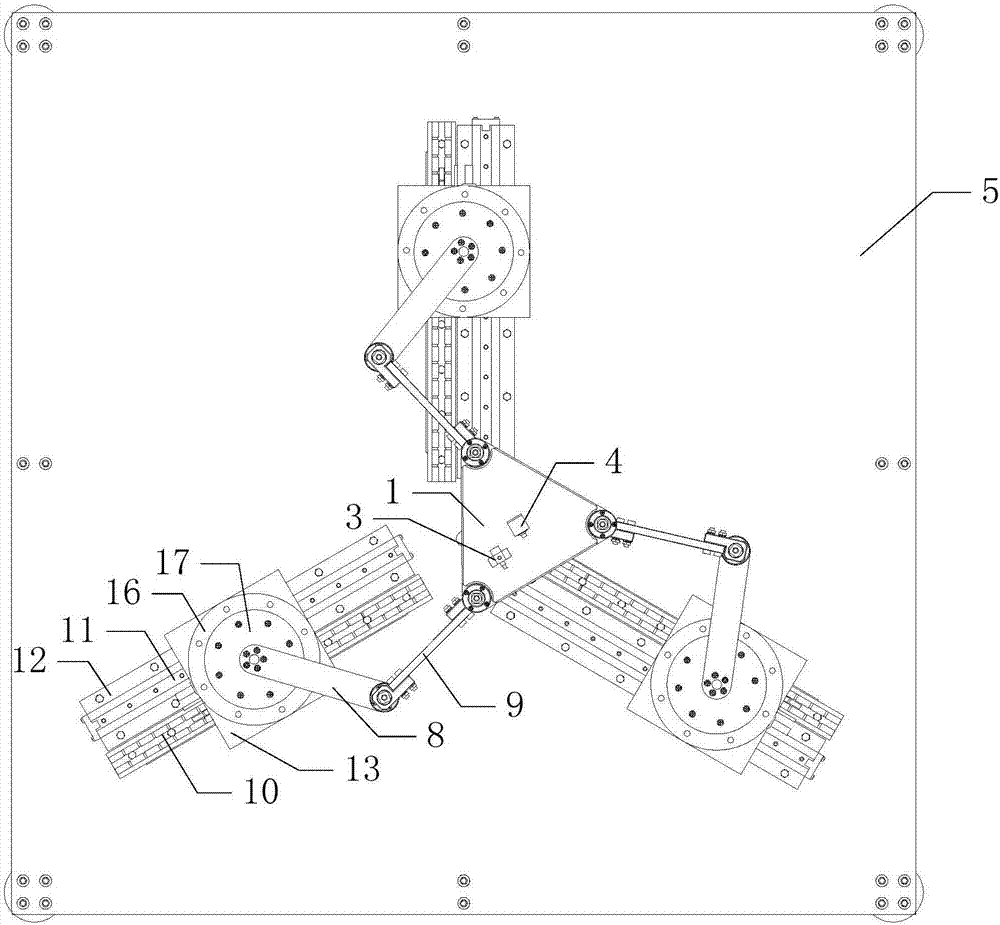

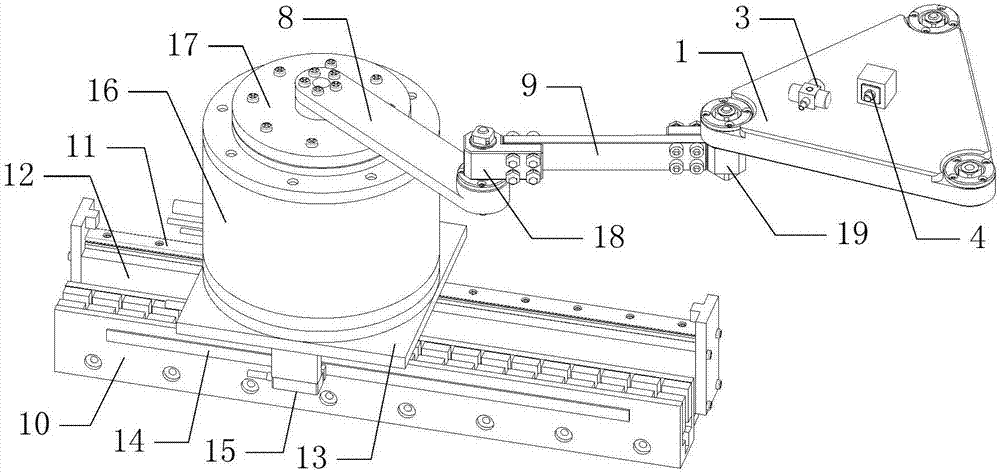

[0040] Such as figure 1 with figure 2 As shown, this embodiment provides a direct-driven redundant planar parallel mechanism control device, the device includes a parallel mechanism body and a control unit, and the parallel mechanism body includes a moving platform 1, a static platform 2 and three parallel branches; figure 1 The dotted line connection in shows the connection diagram of the electrical signal and the body of the parallel mechanism, and the direction arrow shows the transmission direction of the detection and control signal flow.

[0041] The shape of the moving platform 1 is an equilateral triangle, and each corner of the moving platform 1 is provided with a hole, and a second bearing and a second rotating shaft connected to each other are installed in the hole, and are hinged with three parallel branches through the second rotating shaft The moving platform 1 is provided with an angular acceleration sensor 3 and an acceleration sensor 4, specifically, the ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com