Two-degree-of-freedom large-stroke high-peed and high-precision positioning platform

A positioning platform and large stroke technology, applied in the field of electromechanical, can solve the problems of low reciprocating positioning accuracy, difficult ball screw processing, and limited application range, etc., and achieve low cost, reduced complexity and size, and quick results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

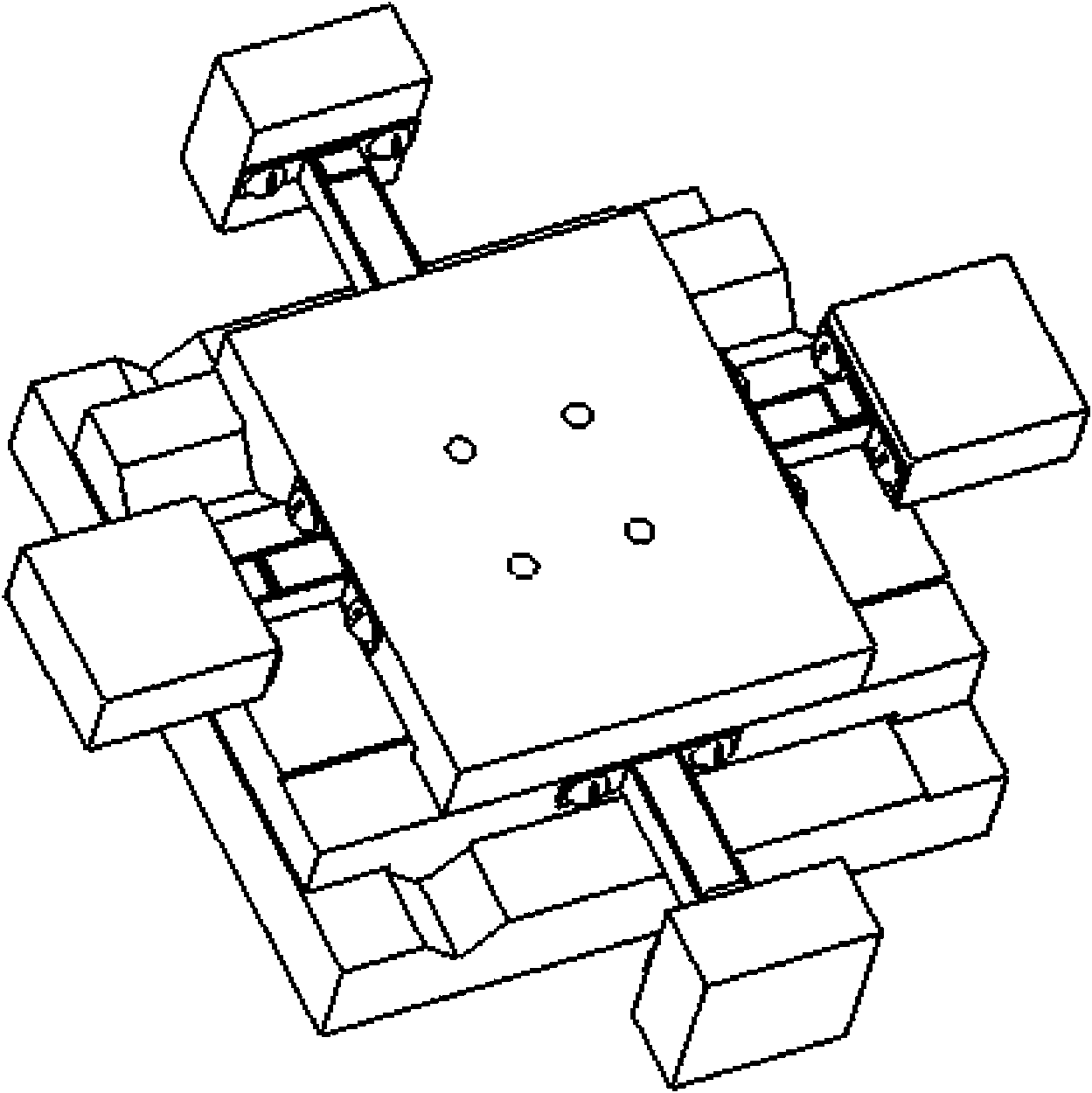

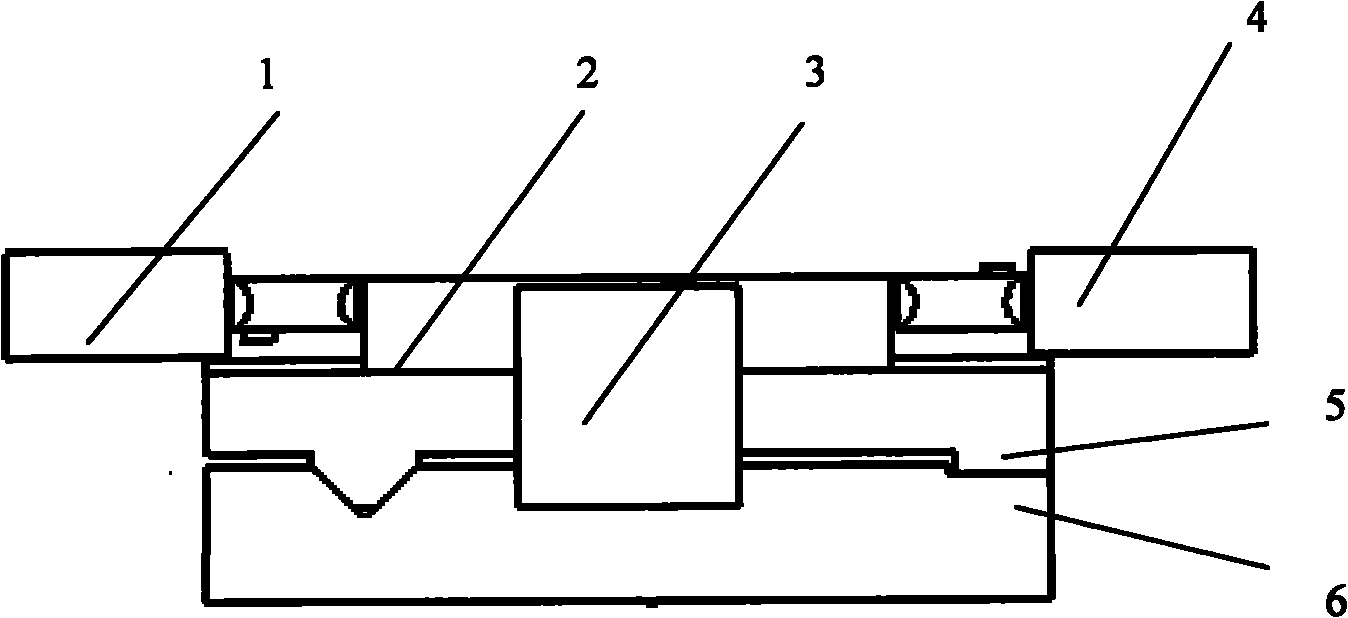

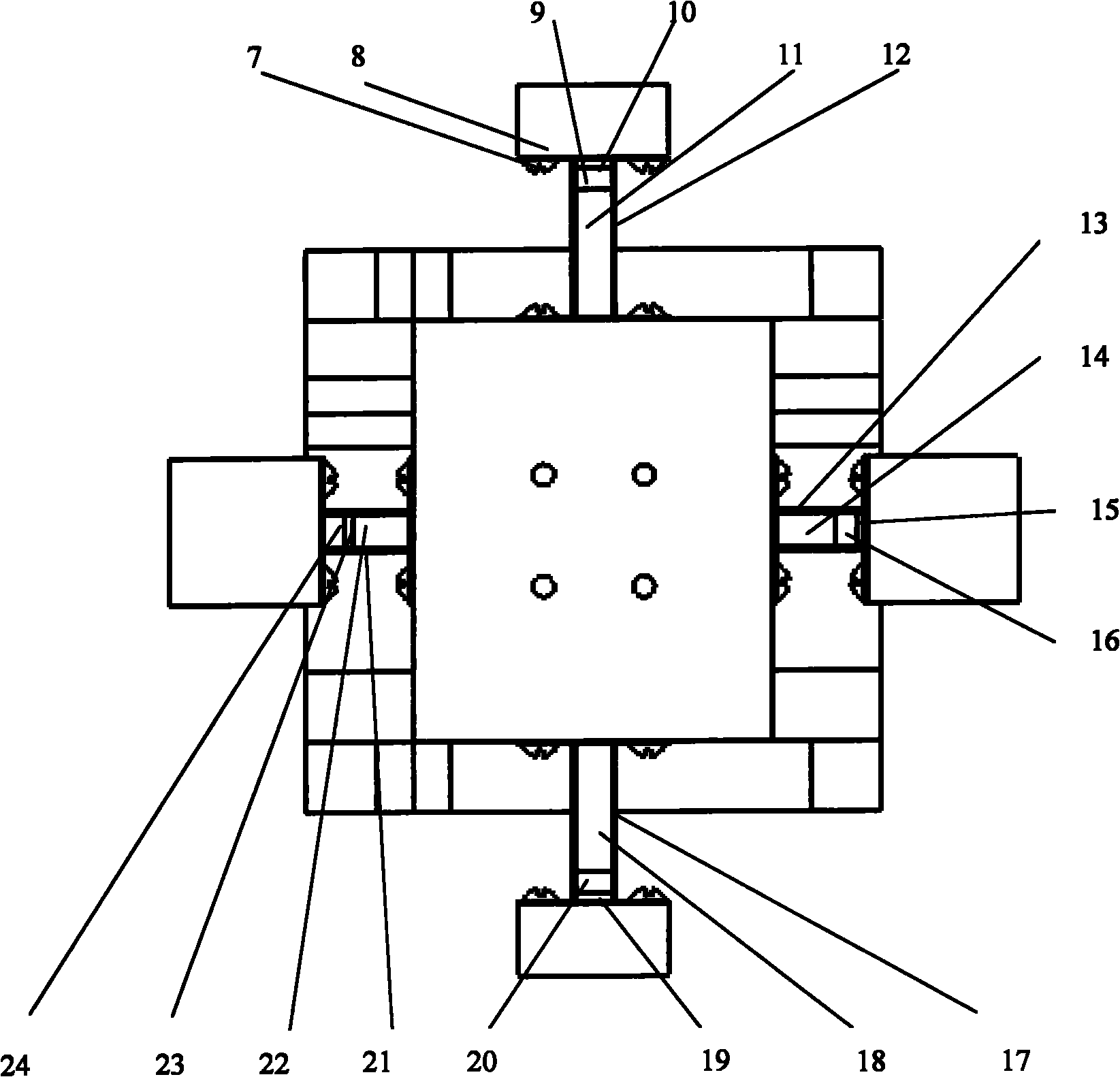

[0013] see Figure 1 to Figure 4 , the two-degree-of-freedom, large-stroke, high-speed, high-precision positioning platform of the present invention includes: guide rail I5, guide rail II6 that cooperate with each other, and workbench 2 driven by guiderail I5, wherein, workbench 2 passes through flexible hinge I21, flexible hinge II13 and mass block respectively I1, mass block II4 are connected; piezoelectric stack I14, piezoelectric stack II22 are carried out in flexible hinge I21, flexible hinge II13 through wedge block I, wedge block II, wedge block III, wedge block IV15, 16, 23, 24 Pre-tightening and positioning; guide rail I5 is connected to mass block III8 and mass block IV3 respectively through flexible hinge III12 and flexible hinge IV17; piezoelectric stack III11 and piezoelectric stack IV18 pass wedge block V, wedge block VI, wedge block VII, Wedge blocks VIII9, 10, 19, 20 are preloaded in flexible hinge III12 and flexible hinge IV17. The movable part is realized by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com