Test specimen fixture for ultrasonic vibration assisted grinding/polishing

A test sample, ultrasonic technology, applied in the field of precision and ultra-precision machining, can solve the problems of limited workpiece shape and size, complicated workpiece clamping, low processing efficiency, etc., to achieve compact structure, large number of clamping, and improved processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

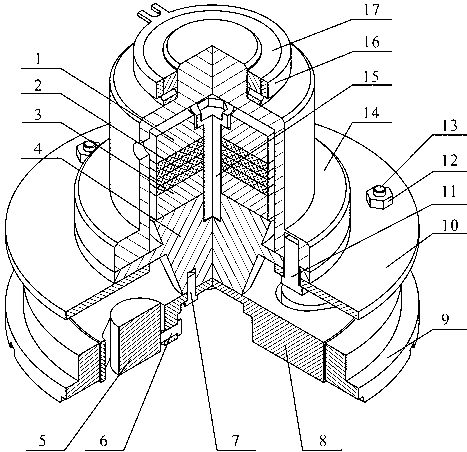

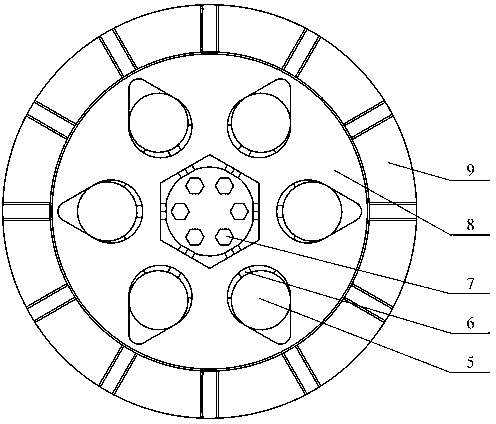

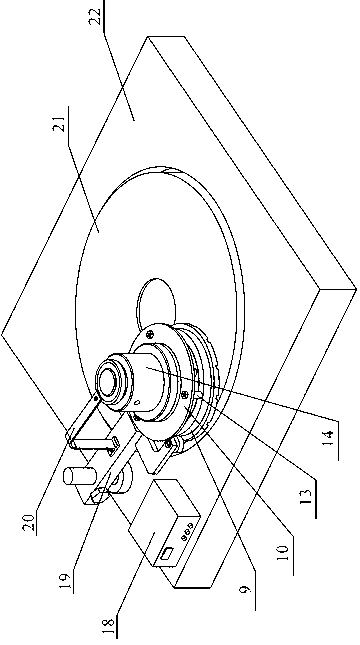

[0017] see Figure 1 to Figure 3 Shown, the test piece sample holder of the ultrasonic vibration assisted grinding / polishing involved in the present invention is designed according to the BNi62 type ultra-precision grinding / polishing machine, and the overall size of the main part of the holder is 210mm×210mm×170mm, and the size of the holder is based on a diameter of 500mm grinding disc / polishing disc is designed, the size of the fixture can be adjusted according to the diameter of the grinding disc / polishing disc, but it must be ensured that the diameter of the dressing ring is greater than the contact length with the grinding disc, so as to ensure that the dressing ring can hold the entire The grinding disc is trimmed to ensure the flatness of the grinding disc. The clamp can be easily installed on the polishin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com