Electrically-controlled light spot shaping and power adjusting device, system and method based on diaphragm

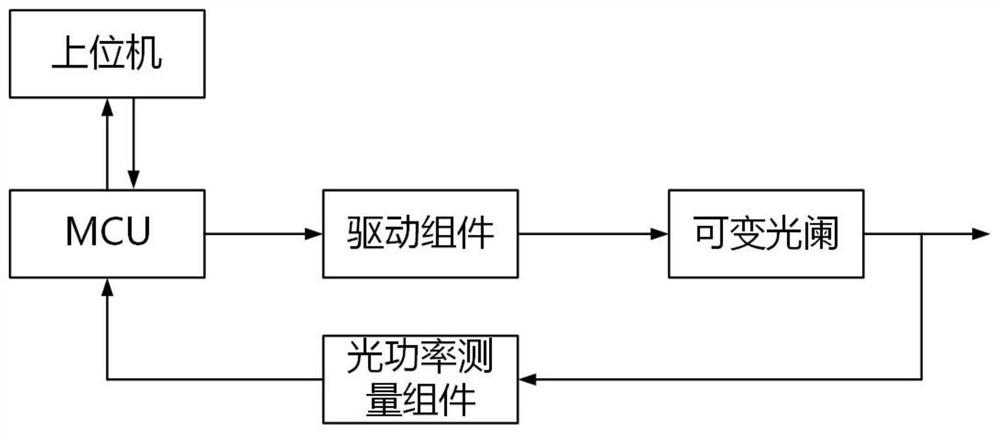

A power adjustment system and power adjustment technology are applied in the fields of optics, optical components, and photometry using electric radiation detectors. It can solve the problems of increased cost, limited application, and continuous adjustment of the diaphragm, and achieves easy Realize and prepare the effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

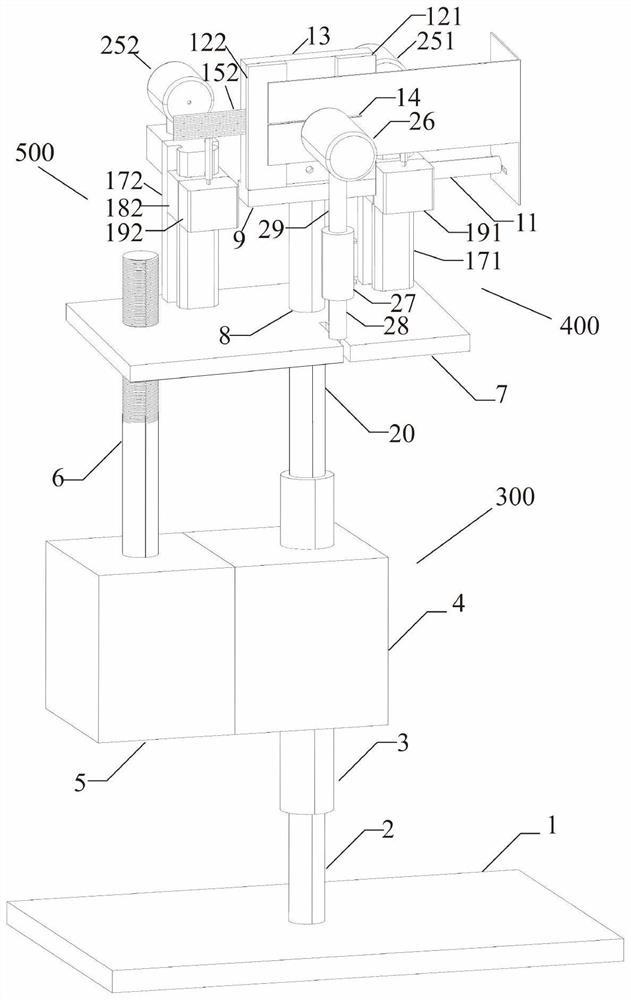

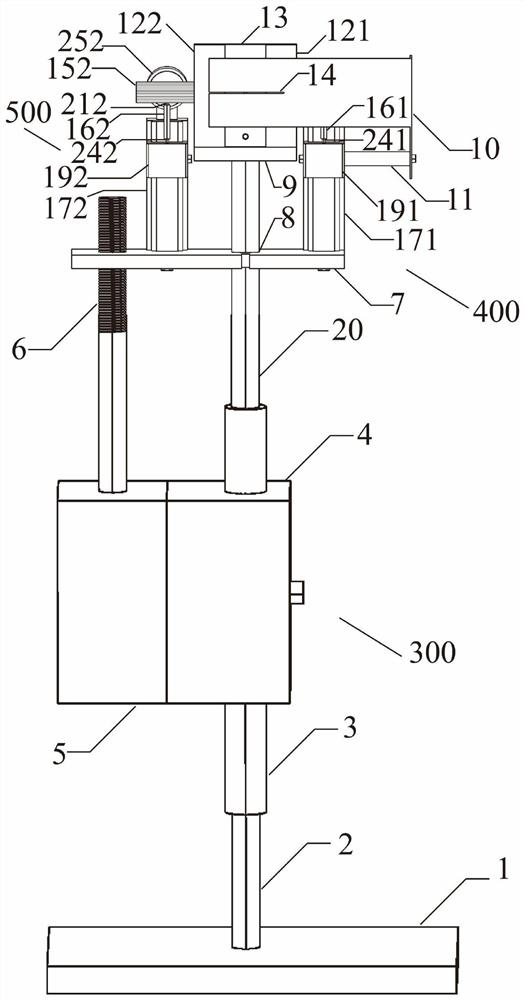

Embodiment 1

[0070] like Figure 9 Shown is the application of a diaphragm-based electronically controlled spot shaping and power adjustment device and method in the manufacture of optical fiber devices. When multiple fiber gratings are prepared at the same time, multiple fibers are distributed along the Y-axis direction, and the X-axis is required. The spot power corresponding to each optical fiber in the direction is equal, otherwise, the reflectivity of each fiber grating will be inconsistent when prepared at the same time. Due to the irregular distribution of the spot power, the adjustment difficulty is increased. The 2G152 divides the light spot into multiple thin strip-shaped light spots, and adjusts the optical power of the thin-striped light spots in turn, and finally achieves the same optical power of the entire light spot, so that the power of each optical fiber corresponding to the light spot is equal, and the fiber grating with the same reflectivity is prepared.

[0071] The li...

Embodiment 2

[0081] like Figure 10 As shown, the light spot before adjustment is a trapezoidal light spot. If you want to get a rectangular light spot, adjust the thin cylindrical component 1151 and thin cylindrical component 2G152 to form a rectangular aperture, and the trapezoidal light spot passes through the light hole and the thin cylindrical component. The aperture will get a rectangular light spot, which includes the following steps:

[0082] 1. Adjust the height of the transmission mechanism 1Y300 so that the movable displacement of the transmission mechanism 1Y300 covers the position of each thin cylinder of the thin cylinder assembly 1151.

[0083] 2. Adjust the height of the transmission mechanism 2Y400 so that the height of the transmission wheel 1W231 is consistent with the height of the first thin cylinder corresponding to the light spot, and use the electron microscope 1K251 to observe the degree of fit between the transmission wheel 1W231 and the first thin cylinder corres...

Embodiment 3

[0087] like Figure 11 As shown, adjusting the trapezoidal light spot into an elliptical light spot includes the following steps:

[0088] 1. Adjust the height of the transmission mechanism 1Y300 so that the movable displacement of the transmission mechanism 1Y300 covers the position of each thin cylinder of the thin cylinder assembly 1151.

[0089] 2. Adjust the height of the transmission mechanism 2Y400 so that the height of the transmission wheel 1W231 is consistent with the height of the first thin cylinder corresponding to the light spot, and use the electron microscope 1K251 to observe the degree of fit between the transmission wheel 1W231 and the first thin cylinder corresponding to the light spot, as The initial position of the drive wheel 1W231.

[0090] 3. In the same way, adjust the height of the transmission mechanism 3Y500 so that the height of the transmission wheel 2W232 is consistent with the height of the first thin cylinder corresponding to the light spot, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com