Efficient ethylene removal catalytic module as well as preparation method and application thereof

An ethylene and high-efficiency technology, which is applied in the field of high-efficiency ethylene removal catalytic modules and its preparation, can solve the problems of inability to integrate ethylene removal rate, impossibility of popularization and application, and high cost of use, and achieve stable properties, prevention of pollution, removal efficiency and removal rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

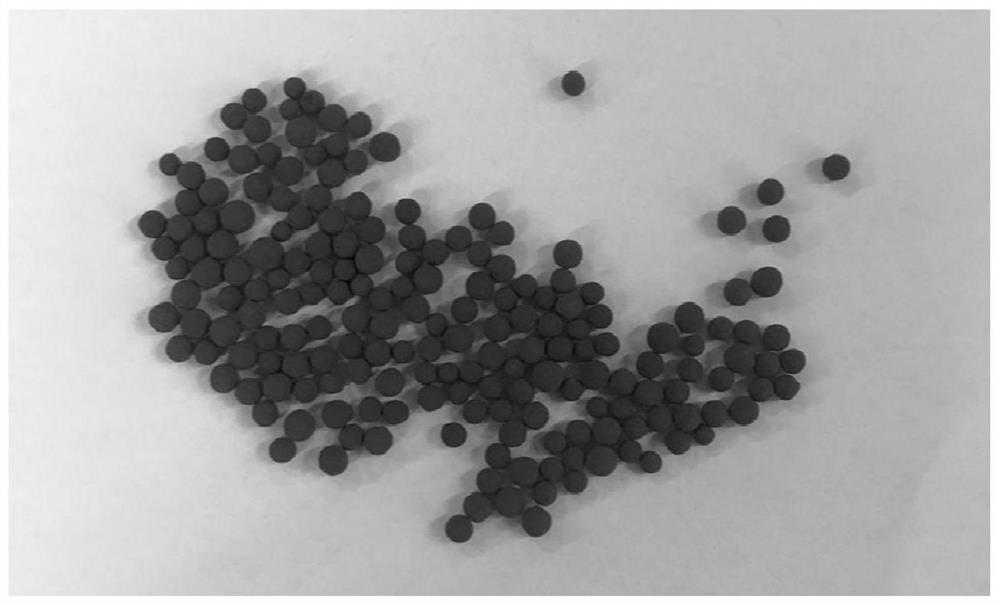

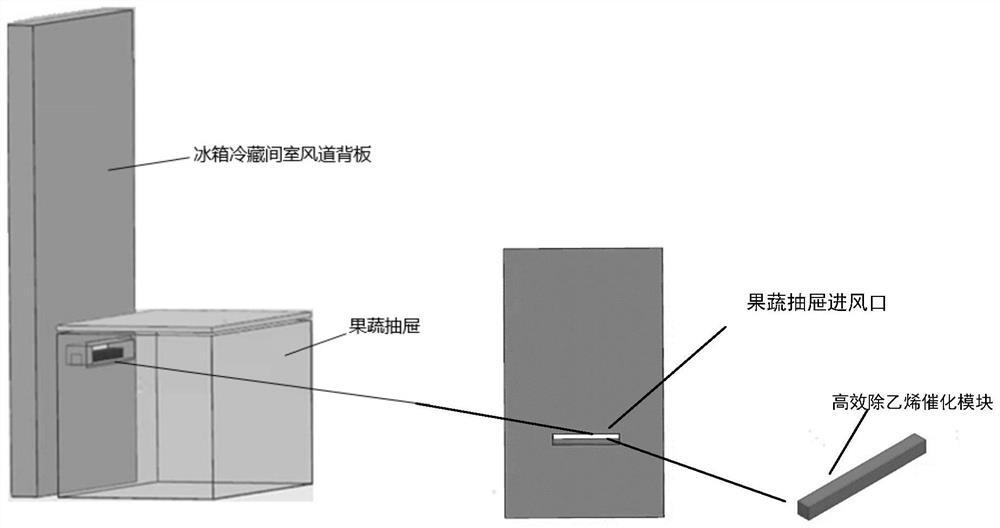

[0053] This embodiment provides a high-efficiency ethylene removal catalytic module, such as figure 1 As shown, the module is strip-shaped, and it is composed of a catalyst and a packaging bag for packaging the catalyst. The specification of the packaging bag is 20mm×100mm, which matches the gap size of the air outlet of the fruit and vegetable drawer of the refrigerator, and contains 3-4g of catalyst.

[0054] Wherein, the catalyst is composed of main catalyst, auxiliary catalyst, carrier and auxiliary curing material. Such as figure 2 As shown, the catalysts are spherical particles with a particle size 2 o 4 and MnCo 2 o 4 mixture of ZnCo 2 o 4 and MnCo 2 o 4 The mass ratio is 1:1. The auxiliary catalyst is a transition metal semiconductor compound, specifically a mixture of cuprous oxide and nickel oxide, and the mass ratio of cuprous oxide and nickel oxide is 1:1.

[0055] The preparation steps of the high-efficiency ethylene removal catalytic module are as foll...

Embodiment 2

[0068] This embodiment provides a high-efficiency ethylene removal catalytic module, which differs from Embodiment 1 only in that the noble metal oxides of the main catalyst are different, the components of the auxiliary catalyst are different, the mass ratio of the main catalyst to the auxiliary catalyst is different, and the main catalyst is different from the auxiliary catalyst. The mass ratio of the noble metal oxide to the ternary transition metal oxide of the catalyst is different, the addition amount of kaolin is different, and the others are the same.

[0069] In Example 2, the noble metal oxide is formed by mixing platinum oxide and palladium oxide at a mass ratio of 1:1, the cocatalyst is a mixture of zinc oxide, nickel oxide and copper oxide, and the mass of zinc oxide, nickel oxide and copper oxide The ratio is 1:1:1, the mass ratio of the main catalyst and the auxiliary catalyst is 1:4, the mass ratio of the noble metal oxide of the main catalyst and the ternary tr...

Embodiment 3

[0071] This embodiment provides a high-efficiency ethylene removal catalytic module, which differs from Embodiment 1 only in that the noble metal oxides of the main catalyst are different, the components of the auxiliary catalyst are different, the mass ratio of the main catalyst to the auxiliary catalyst is different, and the main catalyst is different from the auxiliary catalyst. The mass ratio of the noble metal oxide to the ternary transition metal oxide of the catalyst is different, the addition amount of kaolin is different, and the others are the same.

[0072] In embodiment 3, the precious metal oxide is platinum oxide, and the cocatalyst is the mixture of zinc oxide and nickel oxide, and the mass ratio of zinc oxide and nickel oxide is 1:1, and the mass ratio of main catalyst and auxiliary catalyst is 1:5, The mass ratio of the noble metal oxide to the ternary transition metal oxide of the main catalyst is 1:5, and the amount of kaolin added is 9% of the mass of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com