A high-efficiency and high-stability oil immersion device for chemical fiber production and its application method

A high-stability, high-efficiency technology, applied in the field of chemical fiber products, can solve problems such as the difficulty of oil immersion in oil immersion, surface contamination of chemical fiber products, and insufficient oil absorption, etc., to achieve improved tensioning efficiency, stable transportation, and immersion The effect of oil efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

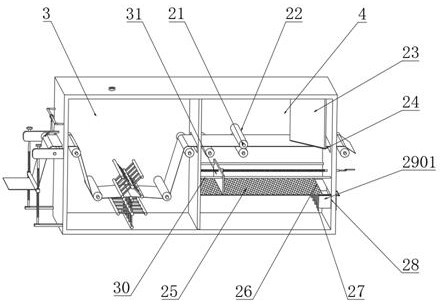

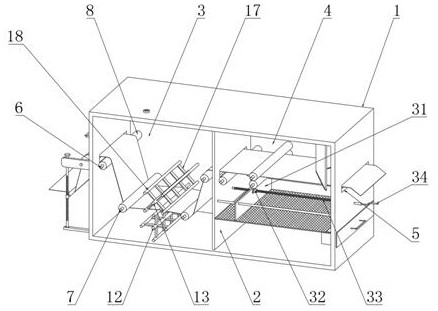

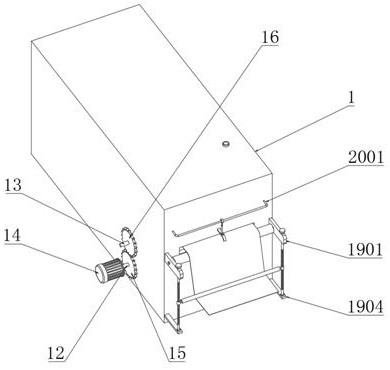

[0050] Example: such as Figure 1-8 As shown, the present invention provides a technical solution, a high-efficiency and high-stability oil immersion device for chemical fiber production, including a box body 1, a partition plate 2 is welded in the middle of the box body 1, and the inside of the box body 1 corresponds to the partition One side of the plate 2 is set as an oil immersion chamber 3 , and the other side of the box body 1 corresponding to the partition plate 2 is set as a recovery chamber 4 .

[0051] The surface on both sides of the top of the cabinet 1 and the top of the partition plate 2 are provided with distribution notches 5, and the inside of the cabinet 1 is equipped with support shafts 6 at both sides of the distribution notch 5 corresponding to the partition plate 2. A support shaft 6 is installed on one side of the opening corresponding to the two sides of the body 1, and a lower pressing shaft 7 is installed at the bottom of the oil immersion chamber 3. ...

Embodiment 2

[0063] Embodiment 2: as Figure 1-8 As shown, a method of using a high-efficiency and high-stability chemical fiber production device, first inject oil into the box body 1 through the liquid inlet 9, then place the chemical fiber cloth, and move the chemical fiber cloth from the tension sleeve roller 1910 Pass through below, and stretch the chemical fiber cloth from the top of the feeding sleeve roller 1903 into the oil immersion chamber 3 inside the box body 1, and then the chemical fiber cloth penetrates into the oil immersion chamber 3 along the drive sleeve roller 8 installed in the middle Below the drive sleeve roller 8 installed in the middle of the lower pressing shaft 7, and pass through the top of the drive sleeve roller 8 installed in the middle of the support shaft 6 again, the chemical fiber cloth enters the recovery chamber through the distribution slot 5 on the top of the partition plate 2 after being soaked in oil 4, the chemical fiber cloth passes between the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com