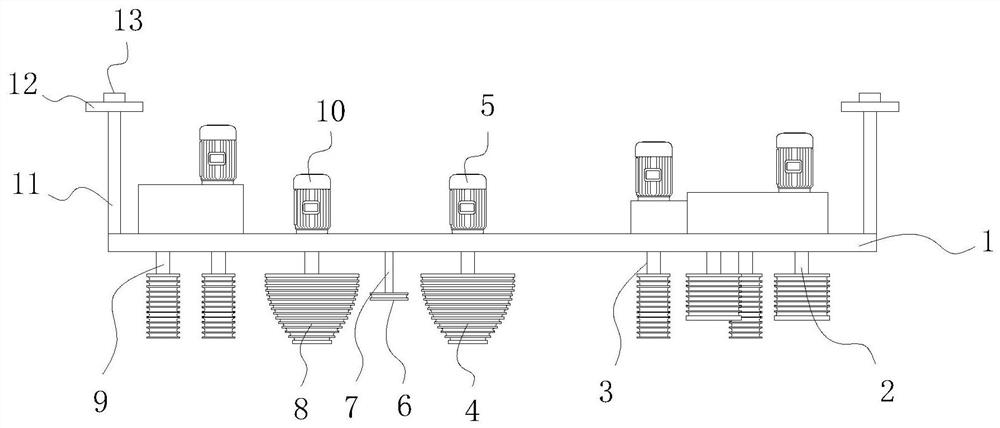

Control rope tensioning device

A technology of tensioning device and control rope, which is used in auxiliary equipment for rope making, transportation and packaging, textiles and papermaking, etc., can solve the problems of control rope rebound, low production efficiency, etc., achieve uniform increase in force and improve efficiency , the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

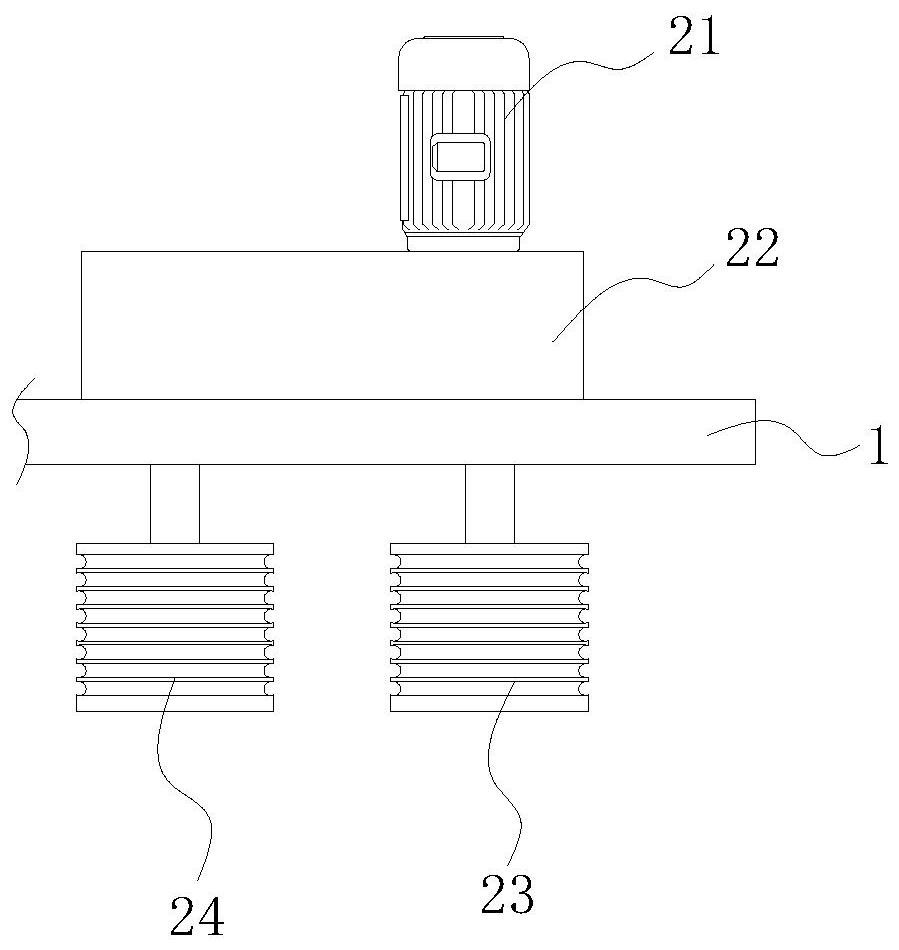

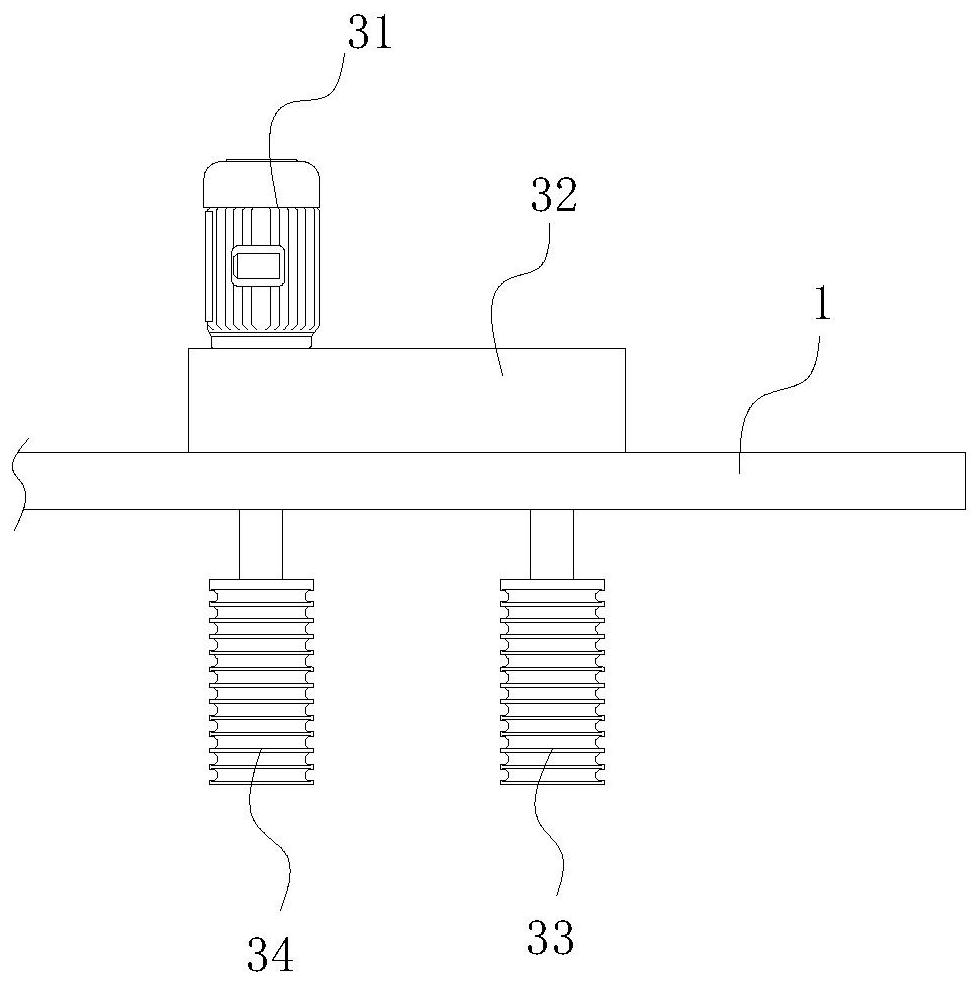

[0029]The specific embodiment: the control rope is crossed around between the first rope-in wheel 23 and the second rope-in wheel 24, and the first motor 21 is run, and the first motor 21 drives the first rope-in wheel through the first gear box 22 23 and the second rope entering wheel 24 rotate in opposite directions to realize the guidance of the steering rope and the pretensioning of the steering rope, and the steering rope is wound in a cross shape between the first rope locking wheel 33 and the second rope locking wheel 34, Run the second motor 31, the second motor 31 drives the first rope locking wheel 33 and the second rope locking wheel 34 to rotate in opposite directions through the second gear box 32, so as to prevent the control rope from rebounding in the direction of the rope inlet assembly 2, that is, Realize the locking of the rope inlet end of the control rope, wind the control rope in a cross shape between the third lock wheel 93 and the fourth lock wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com