Construction method of pipe-jacking working well

A technology for working wells and reverse construction, which is used in construction, artificial islands, water conservancy projects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

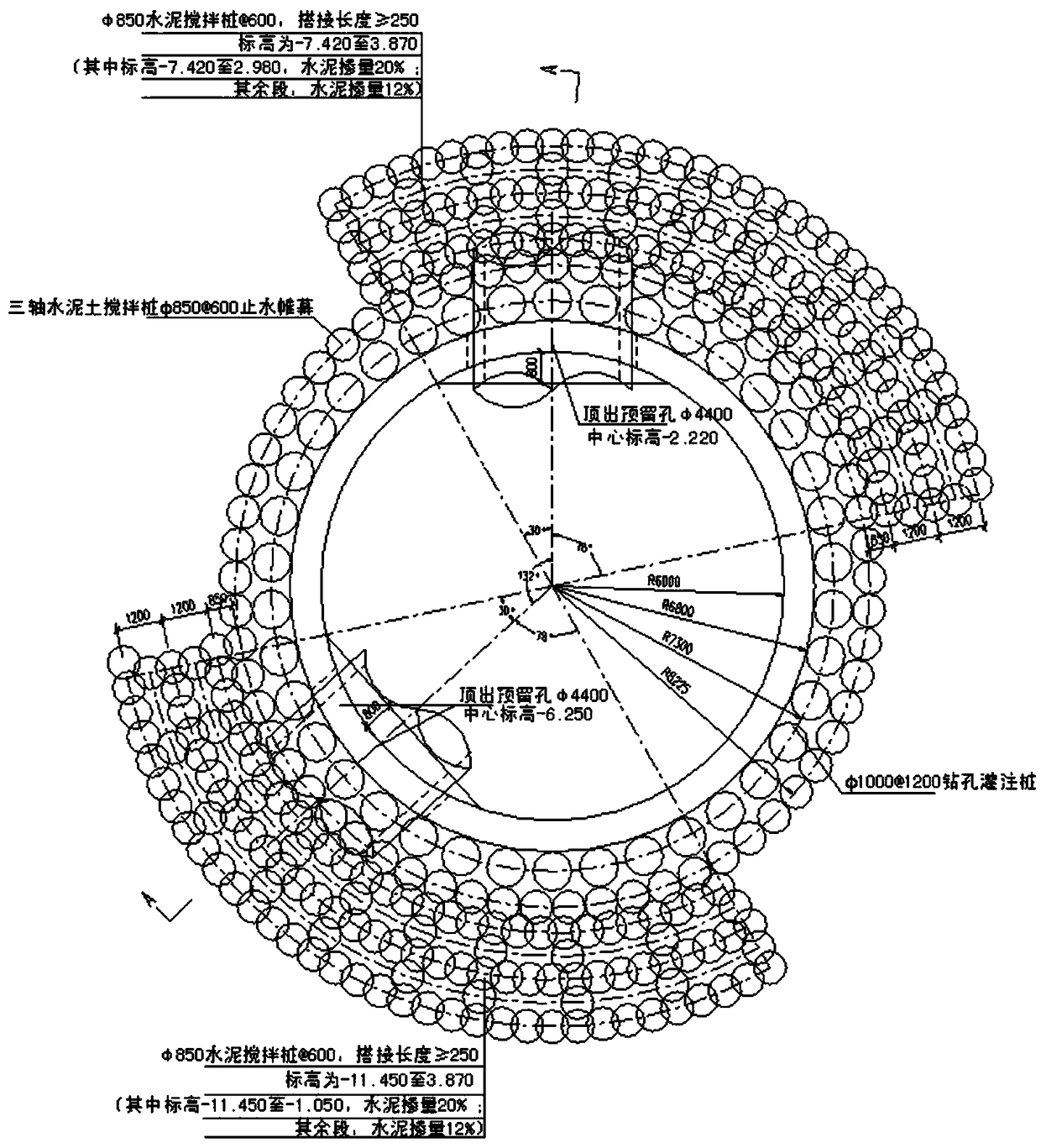

Embodiment 1

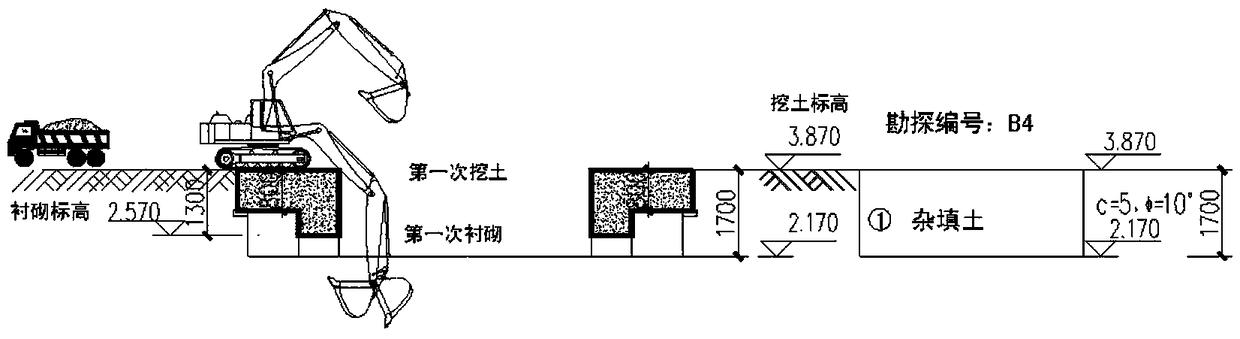

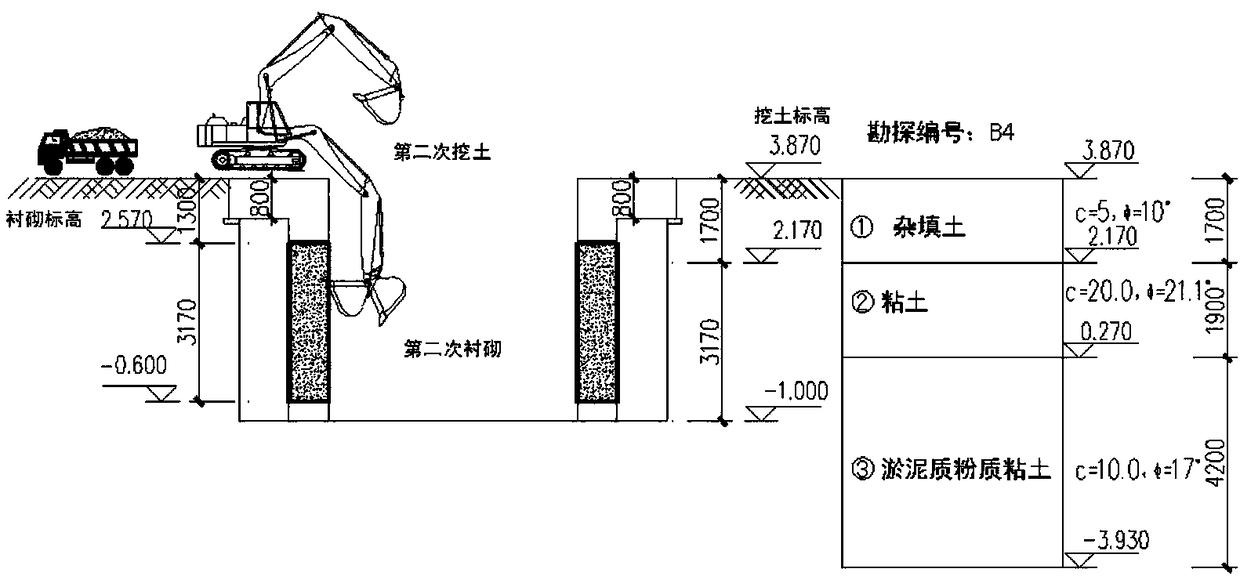

[0034] A certain project "the second bid section of the first phase of the comprehensive renovation of the municipal supporting project in the east area of Hongqiao business district" is located in the east area of Hongqiao business district in Shanghai. Due to the construction scope of the drainage pipeline of this project, the surrounding environment and pipeline conditions are complicated, including: communication Pipelines, aviation oil pipes, cables of urban electric power companies, gas pipelines of Dazhong Gas Company, power pipelines of Hongqiao Airport, and rainwater and sewage pipelines. Therefore, the DN2700-DN3500 rainwater pipes from Yingbin 5th Road to Youle Road are constructed by pipe jacking. The pipe jacking construction process includes 2 working wells and 2 receiving wells. The 4# pipe jacking working well is located at the intersection of Youle Road and Yingbin 1st Road, 30m north of Youle Road. Youle Road is a two-way lane. Among them, the direction fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com