Construction method for subway tunnel to enter subsurface excavation interval tunnel door from shaft

A construction method and shaft technology, which is applied to tunnels, tunnel linings, shaft equipment, etc., can solve the problems of unsure construction effect, difficult reinforcement, and difficult operation, so as to avoid the increase of arch replacement costs and construction risks, and ensure the tunnel Structural and construction safety, and the effect of reducing the difficulty of construction work at heights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

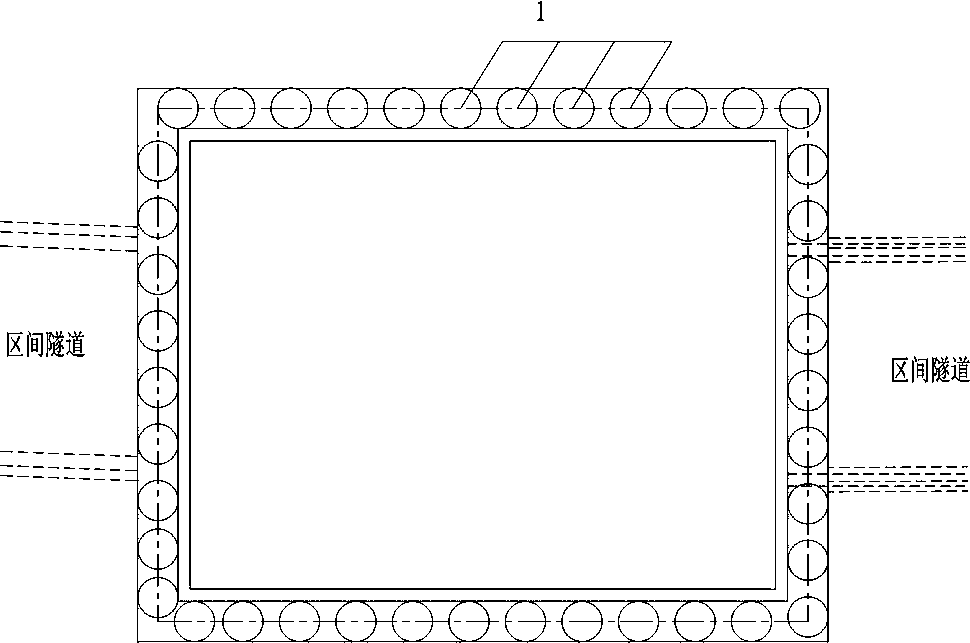

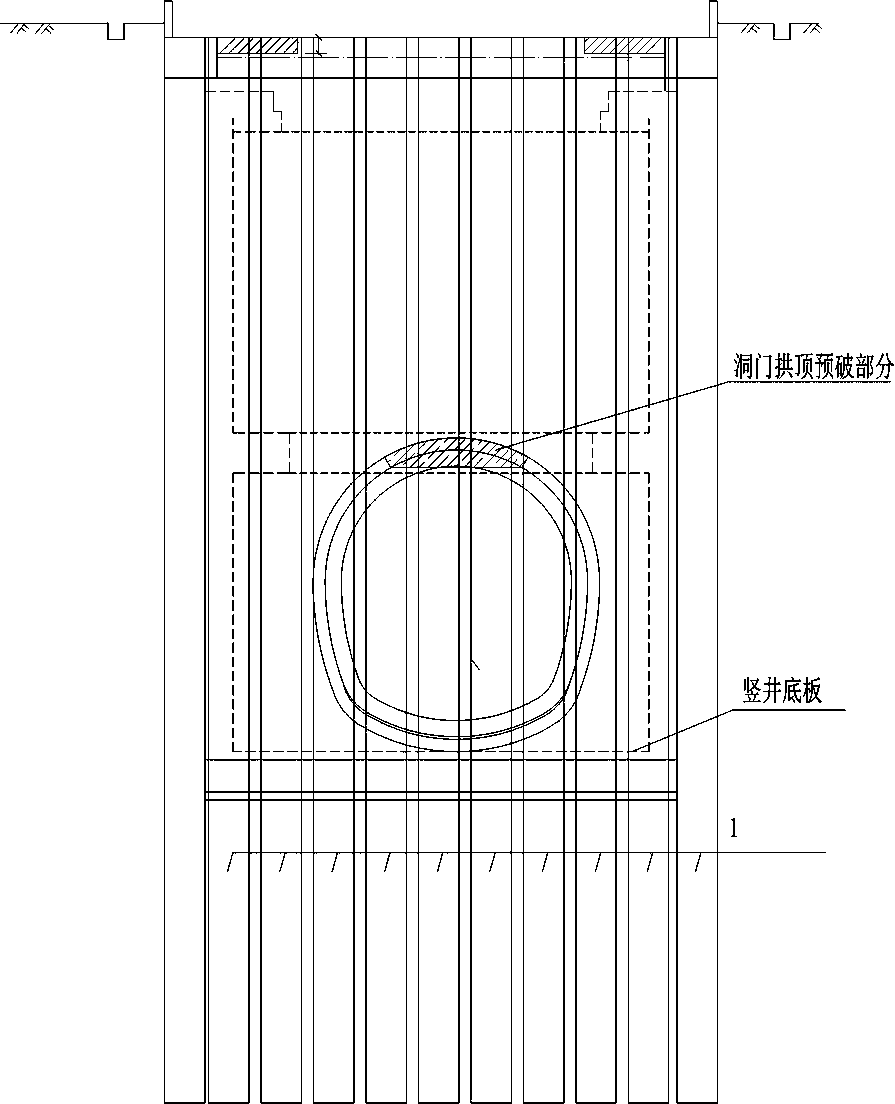

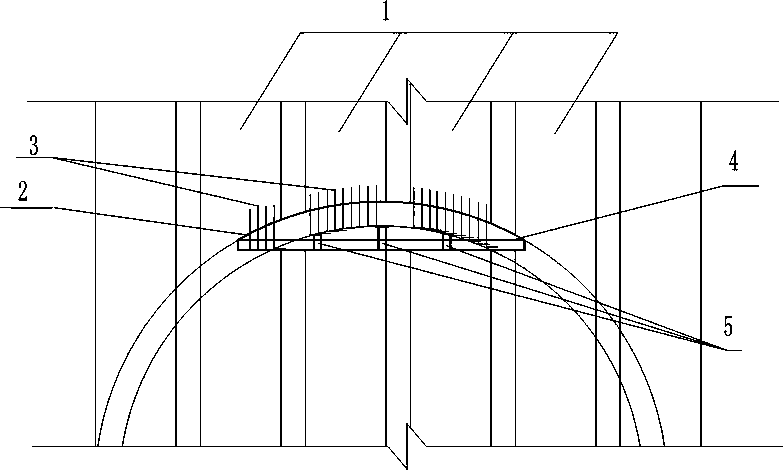

[0031] Example 1: In the Xiang-fang section of Xi’an Metro Line 9, a shield tunneling shaft is installed on the left and right lines of the shield tunneling section and the underground excavation section. The shield tunneling shaft is the receiving shaft of the shield tunneling tunnel in the section, and also serves as the underground excavation construction shaft . The clearance of the shaft is 11.7m×15.1m, of which the depth of the left-line shaft is 19.3m, and the right-line shaft is 19.5m; the shaft adopts the enclosure structure of "bored piles + steel support", and the number of individual shaft enclosure piles is 41. The shaft is also used as an interval flood prevention and civil air defense structure. The main structure of the shaft is an underground two-story frame structure, and the small mileage defense line is an interval excavated tunnel with a horseshoe-shaped section with a width of 7.1m and a height of 7.7m. Composite lining is adopted, the thickness of primar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com