A combined beam beam and hanging beam device and its hoisting method

A combined and hanging beam technology, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of restricting the integrity of ships or platforms, affecting the construction cycle and cost control of shipyards, and the large amount of legacy work at the wharf. The effect of hoisting requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

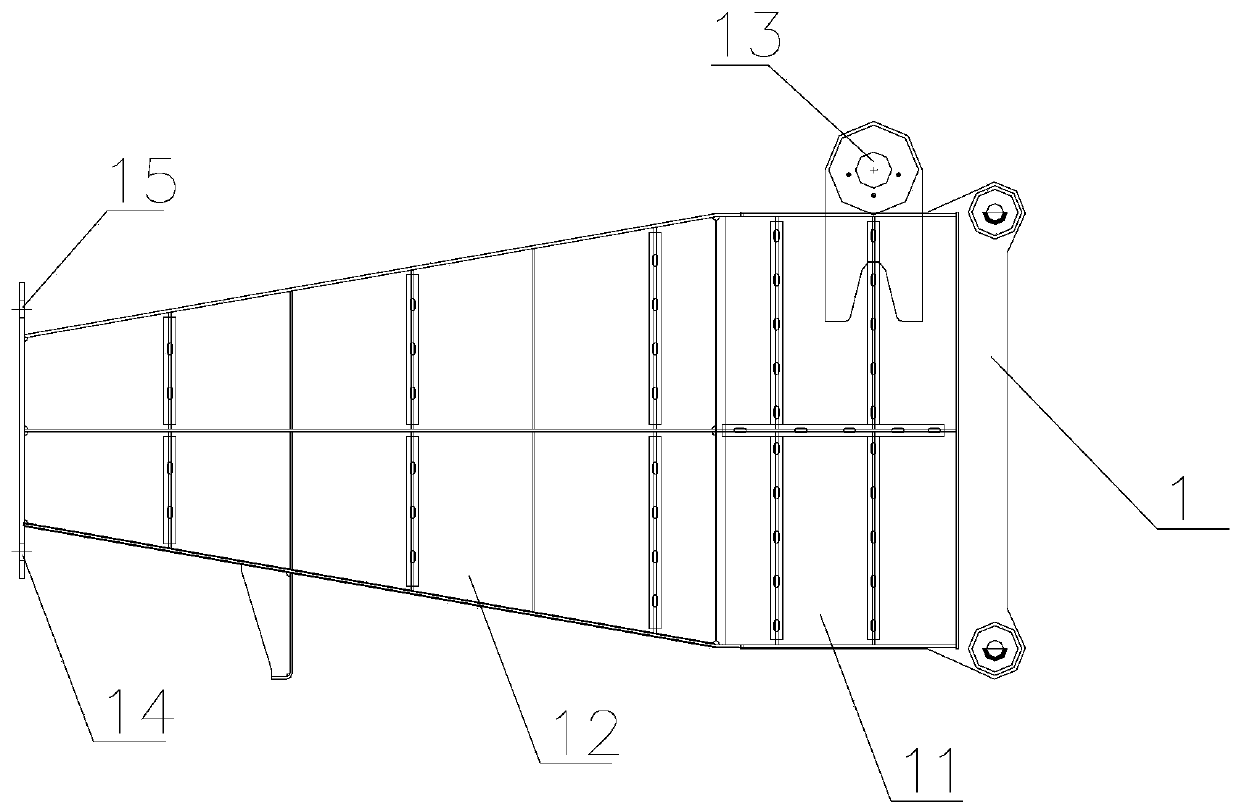

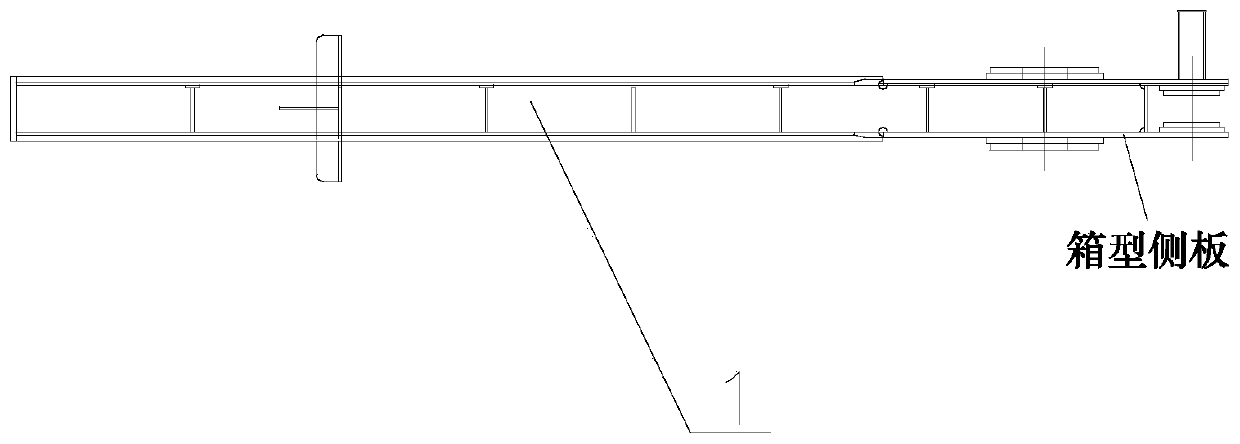

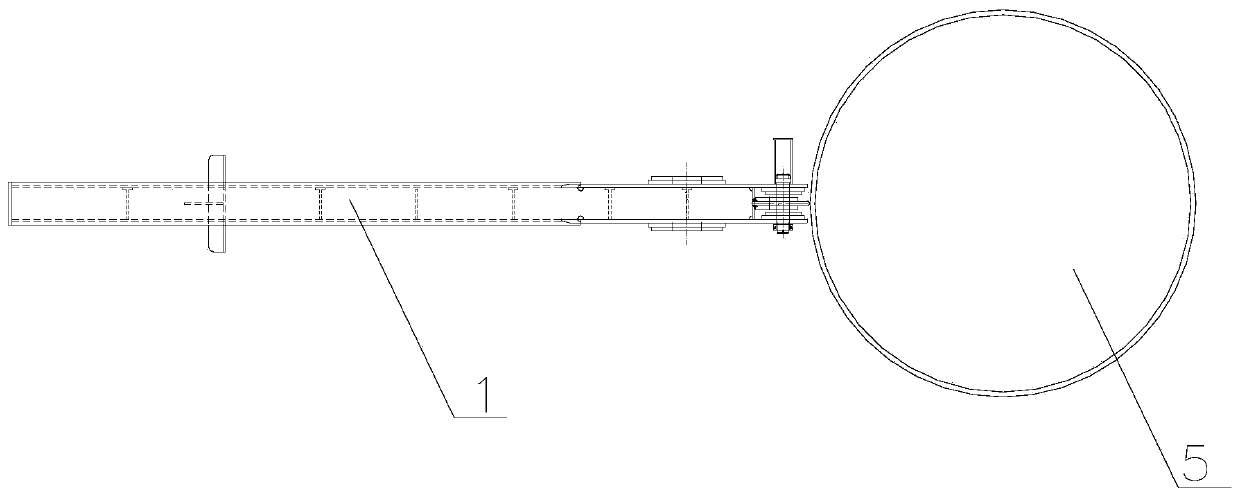

[0041] The combined scale beam and suspension beam device of the present embodiment is as Figure 1-4 As shown, the first beam suspension beam 1 comprising a flat box-shaped structure as a whole, the first beam suspension beam 1 includes a first equal-width section 11 and a first tapered section 12, and a first equal-width section 11 upper end is provided with a first A lifting lug 13, the tail end of the first scale beam 1 is provided with a counterweight connection hole 14, in addition, the end of the first tapered section 12 of the first scale beam 1 corresponds to the counterweight connection hole 14 and an auxiliary suspension is also provided. ear 15.

[0042] When the cross-section of the suspended object 5 is a circular or rectangular columnar frame structure, the end of the first equal-width section 11 of the first scale beam suspension beam 1 is matched with a suitable connecting mechanism such as a hoop or a bolt (specifically, it is only required that the two can b...

Embodiment 2

[0049] The combined scale beam and suspension beam device of the present embodiment is as Figure 5-10 As shown, in addition to the first beam beam 1, the beam beam device also includes a second beam beam 2 and a connecting beam 3. The second beam beam 2 is in a flat box-shaped structure as a whole, and the connecting beam 3 is in a plate shape. structure, and the second beam beam 2 includes a second equal width section 21 and a second tapered section 22, the upper end of the second equal width section 21 is provided with a second lug 23, the first beam beam 1 and the second beam crane The equal width sections of the beam 2 are respectively provided with two high and low hanging beam pin holes 6, and the two ends of the connecting beam 3 are respectively provided with two connecting beam pin holes 7, and the two sides of the connecting beam 3 are respectively inserted into the first scale beam hanging beam 1 and the Between the box-shaped side plates of the second scale beam s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com