Novel lifting appliance for transporting passenger car body

A body and spreader technology, applied in the field of special equipment for vehicle transfer and hoisting, can solve the problems of easy to pierce the roof skin, narrow retraction width, unable to pick up with four claws, etc., so as to avoid manual manual moving and reduce the structure Intensity pressure, the effect of improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

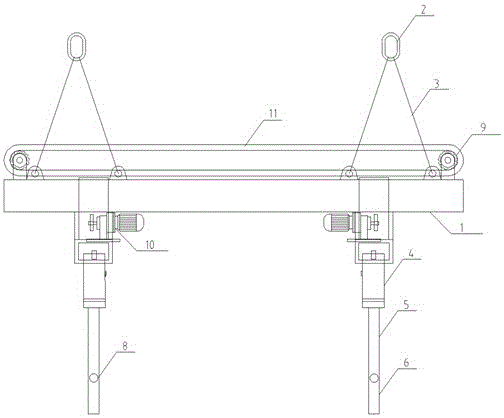

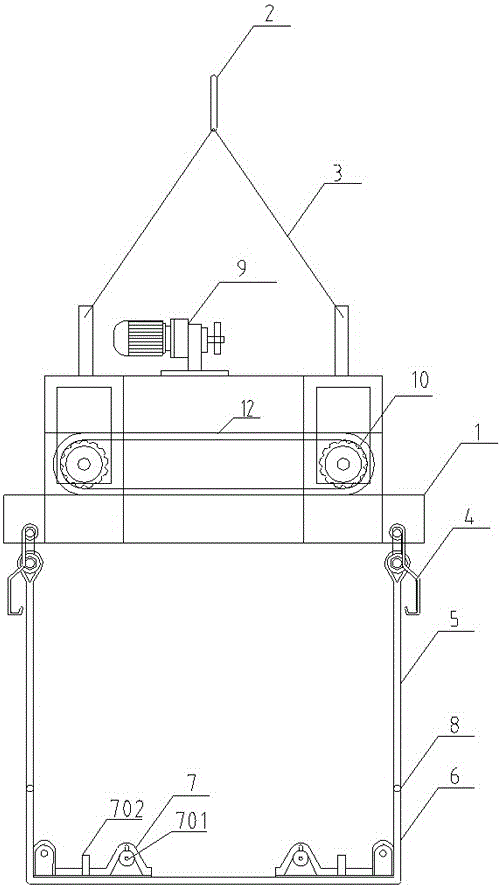

[0026] Embodiment 1 (semi-loaded vehicle body lifting):

[0027] The lifting of the semi-loaded body adopts the method of grabbing from the upper edge of the side window with four lifting claws.

[0028] Adjust the four lifting claws 4 of the spreader to the left and right outermost sides through the length-adjusting reducer 9 and the width-adjusting reducer 10, and hang the spreader to the top of the vehicle body by driving the vehicle, centering front and rear, centering left and right, and the four claws droop freely. Lower the spreader by driving until the four-claw hook exceeds 100±20mm from the lower edge of the side window and stops. Adjust the front and rear positions of the four claws of the spreader so that the four claws are staggered away from the window column. After the front and rear position adjustment of the four claws of the spreader is completed, the four claws are moved closer to the middle by remote control operation, and stop moving when the four claws...

Embodiment 2

[0029] Embodiment 2 (full-carrying vehicle body lifting):

[0030] The hoisting of the full-loaded body adopts the hoisting method that the sling is lifted from the bottom.

[0031] The spreader is hoisted to the top of the vehicle body by driving, and the four lifting point slings 5 are freely drooped by adjusting the position of the length adjustment reducer 9 and the width adjustment reducer 10. Adjust the front and rear positions of the vehicle and the span between the front, rear, left, and right slings of the sling so that the positions of the front and rear slings are aligned with the positions of the lifting hooks on the chassis. Put the two front and rear bottom lifting straps 6 and the supporting brackets 7 for wearing them into the bottom of the vehicle body, and the positions are aligned with the lifting hooks of the bottom frame. Four support bracket hanging shafts 701 are all hung in the lifting hook. The four ends of the bottom support strap 6 are all hung...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com