Precast concrete toilet base plate, manufacturing method and mounting method

A prefabricated concrete and toilet technology, which is applied to indoor sanitary pipe installations, water supply installations, building components, etc., can solve the problems of inability to fundamentally solve the leakage of toilets, few application items, and uncompact hanging holes, and achieve industrialization. The effect of quality control, speeding up the progress of the project and saving the total time of water testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

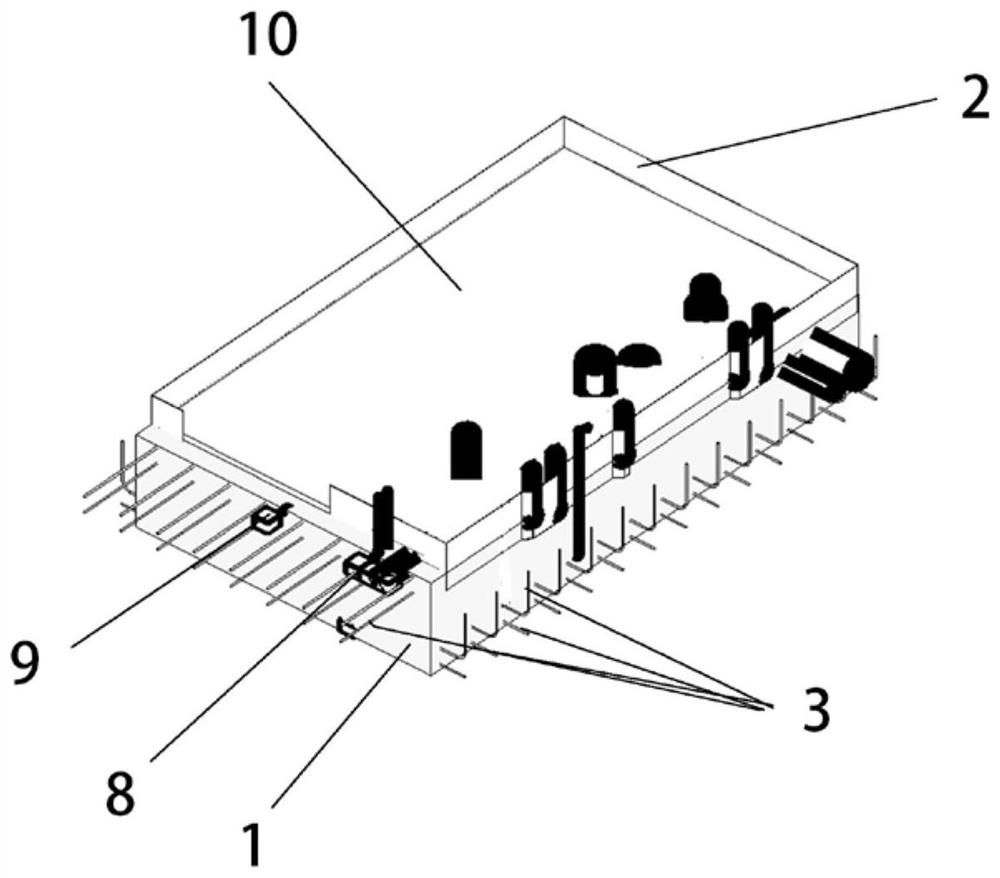

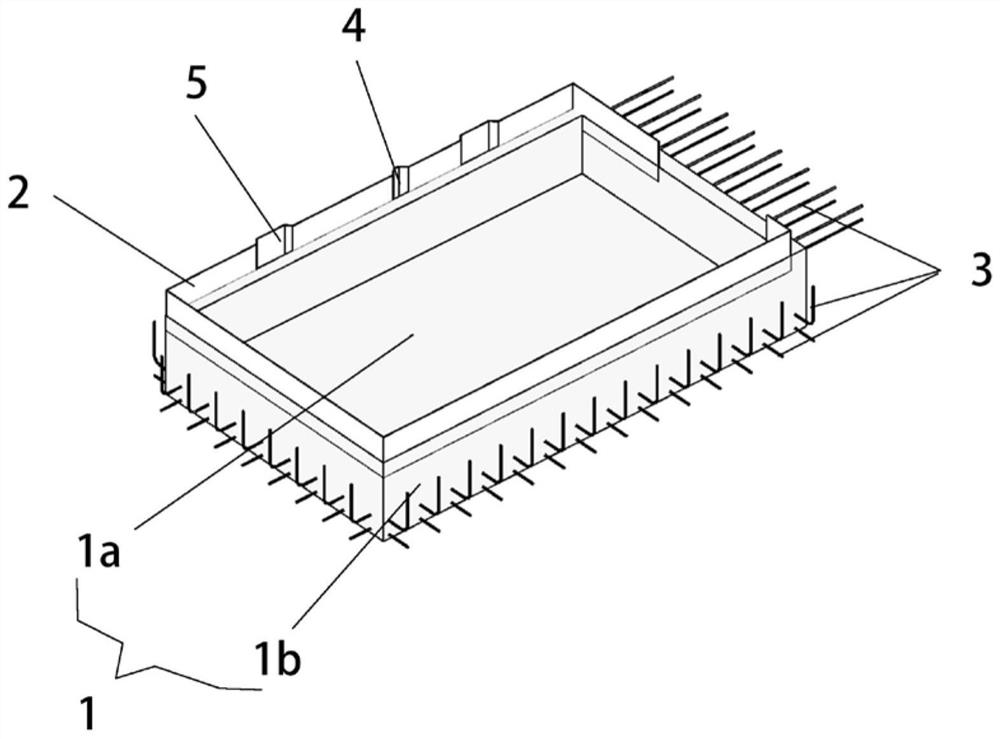

[0081] A prefabricated concrete bathroom chassis, the bathroom chassis including concrete caskets and sills.

[0082] The concrete cassette is a rectangular case formed by the bottom plate and the side wall;

[0083] In the present embodiment, the length width of the concrete cassette is 1612 mm * 2706mm * 350 mm; the side wall thickness is 75 mm; the thickness of the bottom plate is 120 mm;

[0084] Two-layer steel construction surface is provided in the bottom plate of the concrete cassette; the two-layer horizontal steel structure is formed by the steel bar in the vertical and horizontal direction, and the grid is interlaced, and the concrete casket is extended to reserve the exposed steel bar. The exposed steel bars in this point are 10 @ 200;

[0085] The upper end of the concrete cassette reserves the exposed steel bar in the horizontal direction, and the exposed steel bars are dimensored here is 6 @ 150;

[0086] The upper end of the concrete cassette is provided with a dro...

Embodiment 2

[0101] In the condensed concrete bath of the pre-concrete bathroom chassis produced in the present embodiment, the long-width is 1612 mm * 2706mm * 350mm; the side wall thickness is 75 mm; the thickness of the bottom plate is 120 mm;

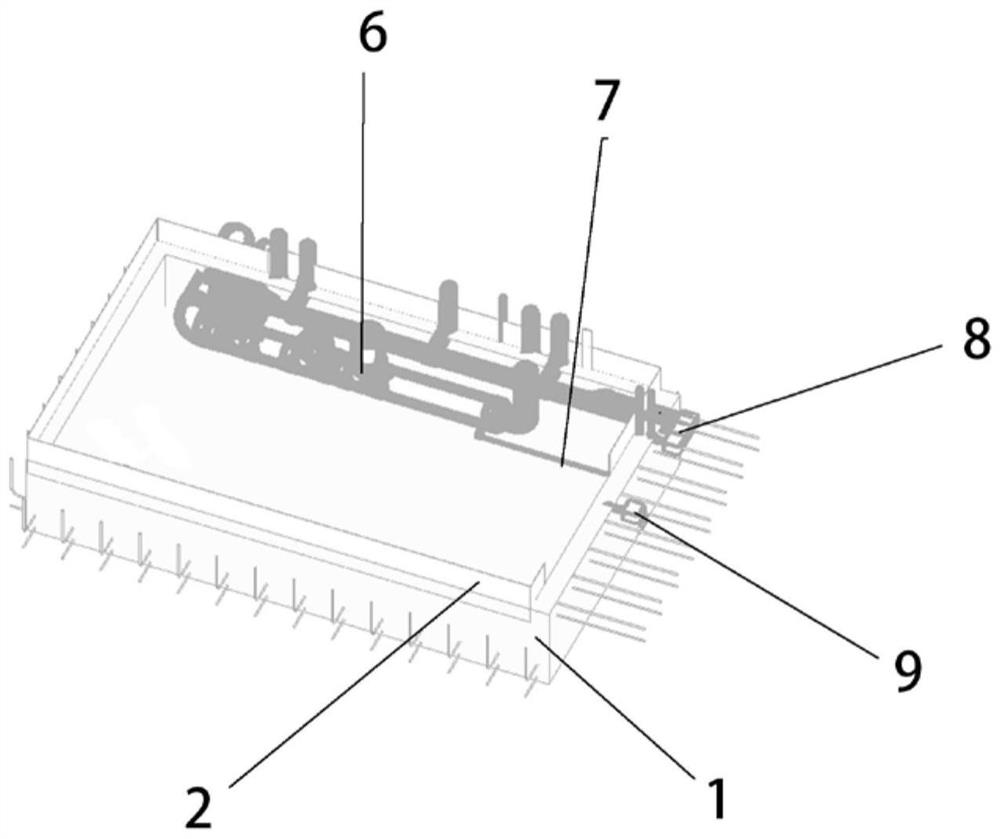

[0102] Prefabricated concrete bathroom chassis production method, showing the following steps:

[0103] A), the mold plant is required to make steel molds according to the size of the pre-concrete bathroom chassis drawings, that is, the steel mold is 1464mm * 2537 * 230mm box structure; in turn, the steel mold is used as a pre-concrete bathroom chassis template to zoom in concrete sink bottom and surrounded steel bars. , Form a steel wire, and secure the soiled steel plate to the sink steel wire to form a anti-slash, thereby presetting the drainage and electric wire in the anti-slave anti-kan;

[0104] The bottom of the concrete cassette is built on two levels of horizontal reinforced buildings. The two-layer steel bar construct surface is composed ...

Embodiment 3

[0112] In the present embodiment, the length width of the concrete cassette is 1612 mm * 2706mm * 350mm; the side wall thickness is 75 mm; the thickness of the bottom plate is 120 mm; the overall weight is 1.875 tons, and the TC7020 tower crane is used to lift the installation construction; template, sleeve Templates and wall column templates are made of aluminum alloy;

[0113] Prefabricated concrete bathroom chassis installation method, shown by following:

[0114] a), in the first layer, the first layer of wall column steel is binds up, and the height of the wall column steel bar built in this embodiment is 2950 mm, and the wall column, beam plate template, and a prefabricated bathroom chassis support system are installed. And adjust the elevation;

[0115] b), place the prefabricated bathroom chassis to be placed in the installation position of the TC7020 to the installation of the prefabricated bath of the prefabricated bathroom chassis, and install the sleeve template, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com