A light-steel keel composite wood wool panel for external hanging wall panel and manufacturing method thereof

A technology of light steel keel and external hanging wall panels, which is applied in the direction of building components, buildings, building structures, etc., and can solve the problems of insufficient local strength of ordinary wood wool boards, poor thermal insulation and thermal insulation performance of walls, and inability to connect building facades, etc. problem, to achieve the effect of improved heat insulation and sound insulation performance, simple construction and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

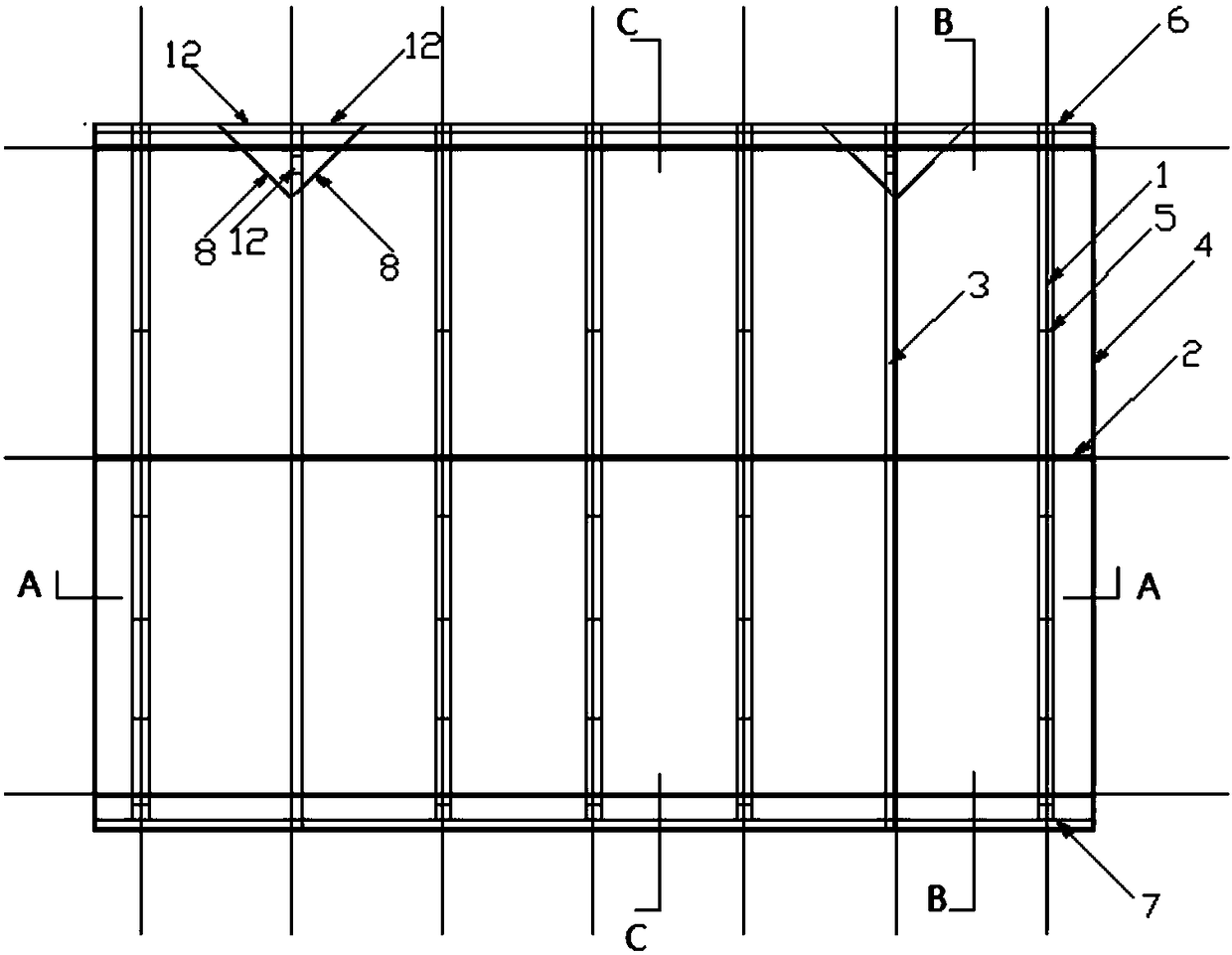

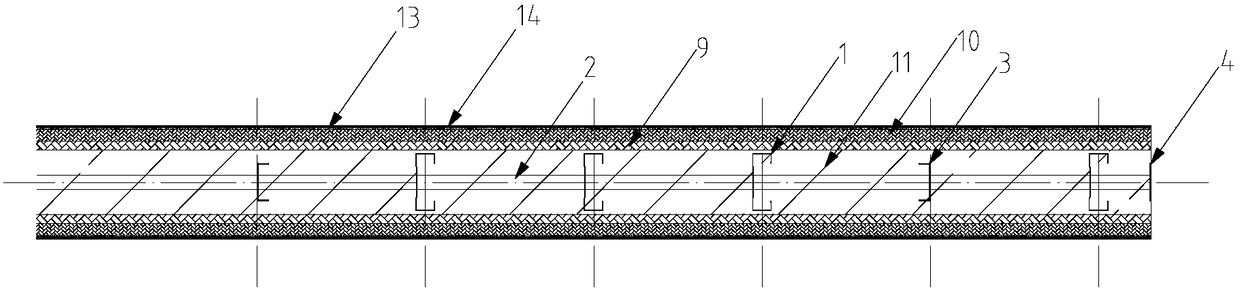

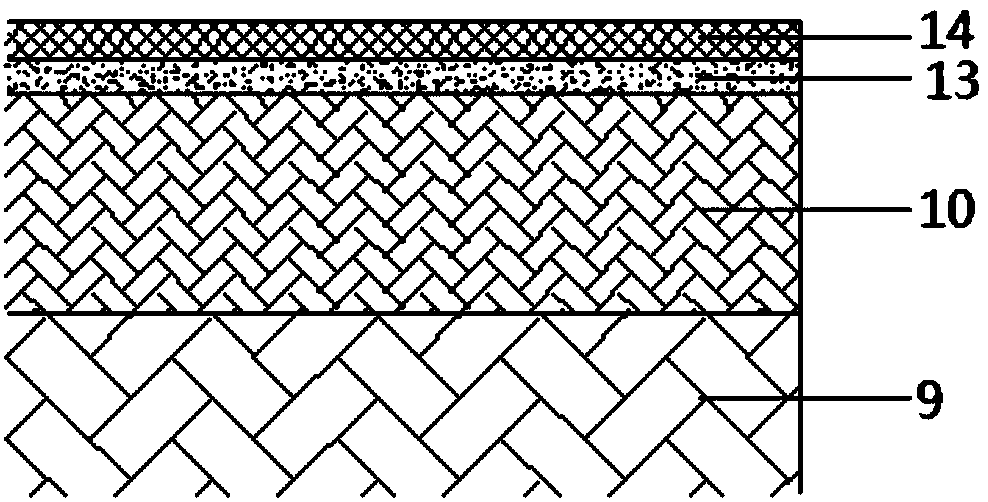

[0036] A light steel keel composite wood wool panel for external hanging wall panels, such as Figure 1-6 As shown, it includes light steel keel frame, wood wool board and foam concrete 11. The light steel keel frame is composed of five vertical vertical keels 1 and three horizontal through keels 2. The vertical keel 1 is made of cold-formed thin-walled steel. There is a through hole on the thin wall in the middle of the keel 1, and the through keel 2 passes through the through hole of the vertical keel 1, and is connected and fixed by welding at the penetrating part. The vertical keel 1 is also provided with four to six support cards 5 to increase Support strength. The light steel keel skeleton also includes the upper U-shaped steel plate 6 at the top, the lower U-shaped steel plate 7 at the bottom, and the outer steel frames 4 at the left and right ends; The steel frame 4 is connected and fixed by welding at the contact position.

[0037] The wood wool board is connected o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com