Polyurethane sports knee-pad composition and preparation method thereof

A technology of polyurethane and composition, applied in the field of polyurethane sports knee pad composition and its preparation, can solve the problems such as the inability to absorb and disperse impact energy effectively, achieve excellent shock resistance, cushioning and sports comfort, improve protection effect, and facilitate industrial production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

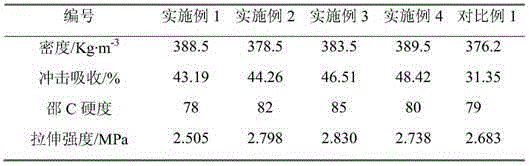

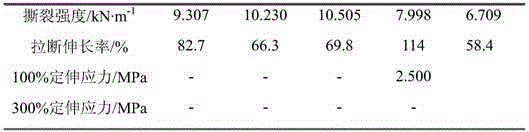

Examples

Embodiment 1

[0047] (1) Preparation of component A materials:

[0048] Weigh respectively: special polyether polyol (hydroxyl value is 270mgKOH / g, functionality is 2.9, with the mixture of propylene glycol and glycerol as initiator) 50Kg, high activity polyether polyol (primary hydroxyl content is 70%) , number average molecular weight is 4000, with glycerol as initiator) 30Kg, polymer polyol POP93 / 28 is 20Kg, chain extender diethylene glycol 1.2Kg, foam stabilizer DC5125 is 1.2Kg, water 3.0Kg, The catalyst Dabco 8154 is 1.3Kg, the antioxidant Chinox TP-22 is 4.1Kg, the light stabilizer Chisorb B2652 is 1.4Kg, and the fine activated calcium carbonate is 2.0Kg. Put the weighed special polyether polyol, highly active polyether polyol, and polymer polyol into the reaction kettle for stirring, and then put in accurately measured chain extender, catalyst, foam blowing agent, foam stabilizer, Light stabilizers, antioxidants, and solid fillers are physically stirred at room temperature for 3.0 h...

Embodiment 2

[0053] (1) Preparation of component A materials:

[0054] Weigh respectively: special polyether polyol (hydroxyl value is 320mgKOH / g, functionality is 3.1, with the mixture of propylene glycol and diethylene glycol as initiator) 65Kg, high activity polyether polyol (primary hydroxyl content is 70%) , the number average molecular weight is 8000, the mixture of glycerol and triethanolamine is the initiator) 20Kg, the polymer polyol POP36 / 28 is 20Kg, the chain extender 1,4-butanediol is 0.6Kg, and the foam stabilizer DC193 is 0.1Kg, water 2.5Kg, catalyst Dabco 33LV is 2.5Kg, antioxidant Chinox TP-10H is 1.6Kg, light stabilizer is a mixture of 1.1Kg Chisorb B2690 and 1.1Kg Chisorb B2652, fine activated calcium carbonate is 4.0Kg. Put the weighed special polyether polyol, highly active polyether polyol, and polymer polyol into the reaction kettle for stirring, and then put in accurately measured chain extender, catalyst, foam blowing agent, foam stabilizer, Light stabilizers, anti...

Embodiment 3

[0059] (1) Preparation of component A materials:

[0060] Weigh respectively: special polyether polyol (hydroxyl value is 300mgKOH / g, functionality is 3.0, with the mixture of propylene glycol, glycerol and trimethylolpropane as initiator) 80Kg, high activity polyether polyol (primary The hydroxyl content is 75%, the number average molecular weight is 5000, with trimethylolpropane as the initiator) 10Kg, the polymer polyol HPOP40 is 8Kg, the chain extender is 0.2Kg 1,6-hexanediol, 0.5Kg ethyl A mixture of glycol and 0.5Kg propylene glycol, foam stabilizer DC6070 is 0.2Kg, water 4.5Kg, catalyst is a mixture of 1.5Kg Dabco 33LV and 1Kg Dabco BL-17, antioxidant Chinox TP-35 is 1.6Kg, light stabilizer Chisorb B2689 is 2.2Kg, and fine activated calcium carbonate is 5.0Kg. Put the weighed special polyether polyol, highly active polyether polyol, and polymer polyol into the reaction kettle for stirring, and then put in accurately measured chain extender, catalyst, foam blowing agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com