Compositing and compounding process for bactericide for oilfield wastewater reinjection treatment

An oilfield sewage and bactericide technology, which is applied in the fields of sterilization/microdynamic water/sewage treatment, mining wastewater treatment, biocide, etc. It can solve the problems of bacterial drug resistance, adapt to a wide temperature range and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

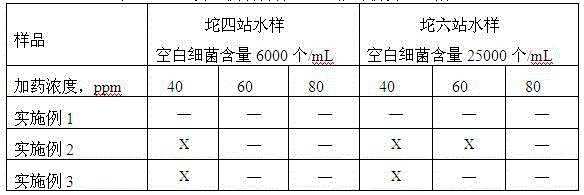

Examples

Embodiment 1

[0021] Embodiment 1: the oilfield sewage reinjection treatment bactericide that the present invention mentions, its synthesis and compounding process are:

[0022] 1) Add 600kg of hexamethylenediamine to the reaction kettle, raise the temperature while stirring, and when the temperature rises to 50°C, add 500kg of aminoformamidine hydrochloride;

[0023] 2) Continue to raise the temperature. When the temperature rises to 100°C, stop heating and react at a constant temperature for 3 hours. While maintaining the temperature, add 10kg of hydrochloric acid as a catalyst dropwise;

[0024] 3) Continue to heat up. When the temperature rises to 120°C, stop heating and react at constant temperature for 12 hours;

[0025] 4) After the reaction is completed, add 1400kg of water and 40kg of hydrochloric acid, the concentration of hydrochloric acid is 30-31% by weight; stir evenly, and the product generated by the reaction is polyhexamethyleneguanidine hydrochloride;

[0026] 5) Add 80...

Embodiment 2

[0029] Embodiment 2: Bactericide for oil field sewage reinjection treatment, its synthesis and compounding process are:

[0030] 1) Add 400kg of hexamethylenediamine to the reaction kettle, heat up under stirring, and when the temperature rises to 50°C, add 200kg of aminoformamidine hydrochloride;

[0031] 2) Continue to raise the temperature. When the temperature rises to 80°C, stop heating and react at a constant temperature for 3 hours. While maintaining the temperature, add 4kg of hydrochloric acid as a catalyst dropwise;

[0032] 3) Continue to heat up. When the temperature rises to 110°C, stop heating and react at constant temperature for 10 hours;

[0033] 4) After the reaction is completed, add 900kg of water and 20kg of hydrochloric acid, the concentration of hydrochloric acid is 30-31% by weight; stir evenly, and the product generated by the reaction is polyhexamethyleneguanidine hydrochloride;

[0034] 5) Add 500kg polyhexamethyleneguanidine hydrochloride to the pr...

Embodiment 3

[0037] Embodiment 3: Bactericide for oil field sewage reinjection treatment, its synthesis and compounding process are:

[0038] 1) Add 500kg of hexamethylenediamine to the reaction kettle, raise the temperature while stirring, and when the temperature rises to 50°C, add 400kg of aminoformamidine hydrochloride;

[0039] 2) Continue to raise the temperature. When the temperature rises to 100°C, stop heating and react at a constant temperature for 3 hours. While maintaining the temperature, add 8kg of hydrochloric acid as a catalyst dropwise;

[0040] 3) Continue to heat up. When the temperature rises to 120°C, stop heating and react at constant temperature for 12 hours;

[0041] 4) After the reaction is completed, add 1200kg of water and 30kg of hydrochloric acid, the concentration of hydrochloric acid is 30-31% by weight; stir evenly, and the product generated by the reaction is polyhexamethyleneguanidine hydrochloride;

[0042] 5) Add 700kg polyhexamethyleneguanidine hydroch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com