Stain-removing and furniture-servicing film plating oil and preparation method therefor

A technology for coating oil and furniture, applied in the direction of biocide-containing paint, antifouling/underwater paint, coating, etc., can solve the problems of inability to protect the paint surface, fingerprint residue, poor hardness, etc., to protect the surface of furniture, improve The effect of paint hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

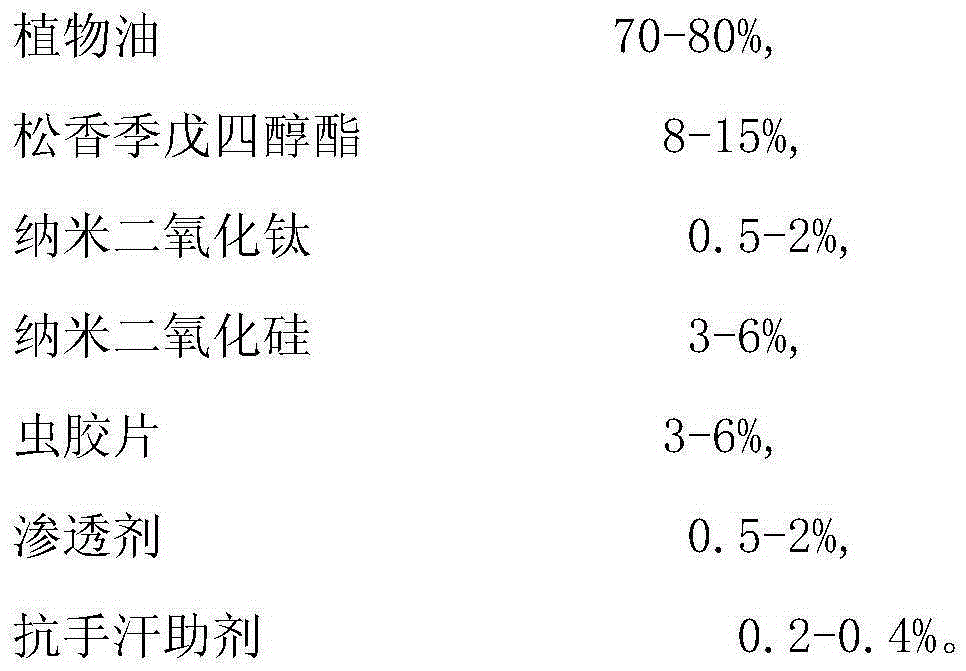

[0038] A coating oil for removing stains and maintaining furniture, comprising the following components by weight ratio:

[0039]

[0040] The preparation method of the above-mentioned coating oil for removing stains and maintaining furniture comprises the following steps:

[0041] (1) Clean the dispersion cylinder with alcohol, dry it, put polymerized linseed oil, tung oil, rosin pentaerythritol ester, nano-titanium dioxide, shellac, catalpa oil, litsea cubeba oil, fatty alcohol polyoxyethylene ether, TEGO435 into the dispersion cylinder to disperse , the speed is 800RMP, and the time is 30min;

[0042] (2) Slowly add cold-pressed orange oil to the mixture treated in step (1), measure the viscosity with Tu-4 cup, adjust the viscosity to 10s, and obtain a semi-finished product;

[0043] (3) Slowly add nano silicon dioxide to the semi-finished product obtained through the treatment in step (2), stir and disperse until it becomes gel, and obtain the finished product;

[004...

Embodiment 2

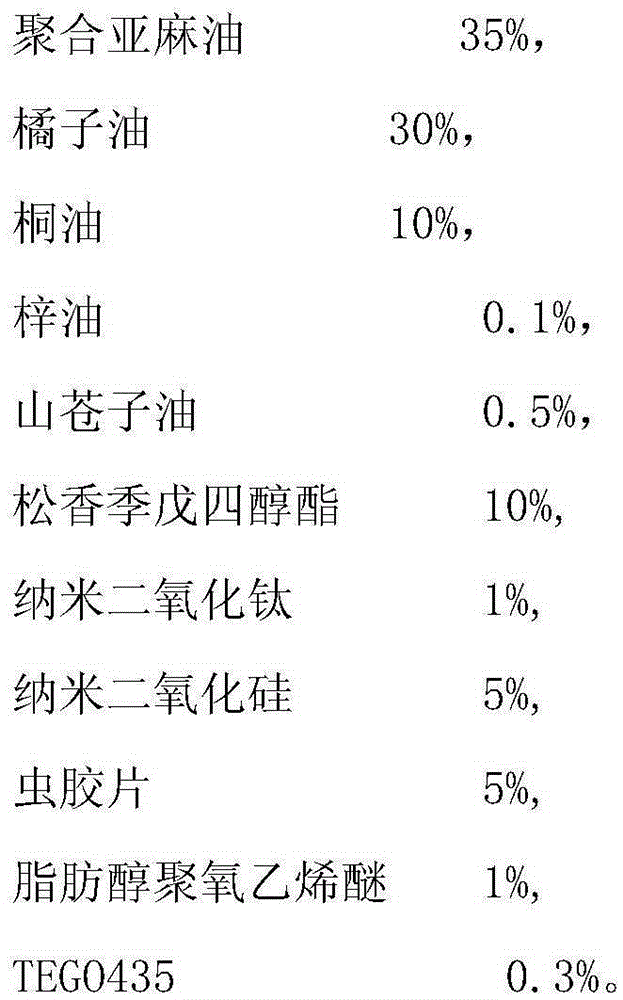

[0050] A coating oil for removing stains and maintaining furniture, comprising the following components by weight ratio:

[0051]

[0052] The preparation method of the above-mentioned coating oil for removing stains and maintaining furniture comprises the following steps:

[0053] (1) Clean the dispersion cylinder with alcohol, dry it, put polymerized linseed oil, tung oil, rosin pentaerythritol ester, nano-titanium dioxide, shellac, catalpa oil, litsea cubeba oil, fatty alcohol polyoxyethylene ether, TEGO435 into the dispersion cylinder to disperse , the speed is 800RMP, and the time is 30min;

[0054] (2) Slowly add cold-pressed orange oil to the mixture treated in step (1), measure the viscosity with Tu-4 cup, adjust the viscosity to 10s, and obtain a semi-finished product;

[0055] (3) Slowly add nano silicon dioxide to the semi-finished product obtained through the treatment in step (2), stir and disperse until it becomes gel, and obtain the finished product;

[005...

Embodiment 3

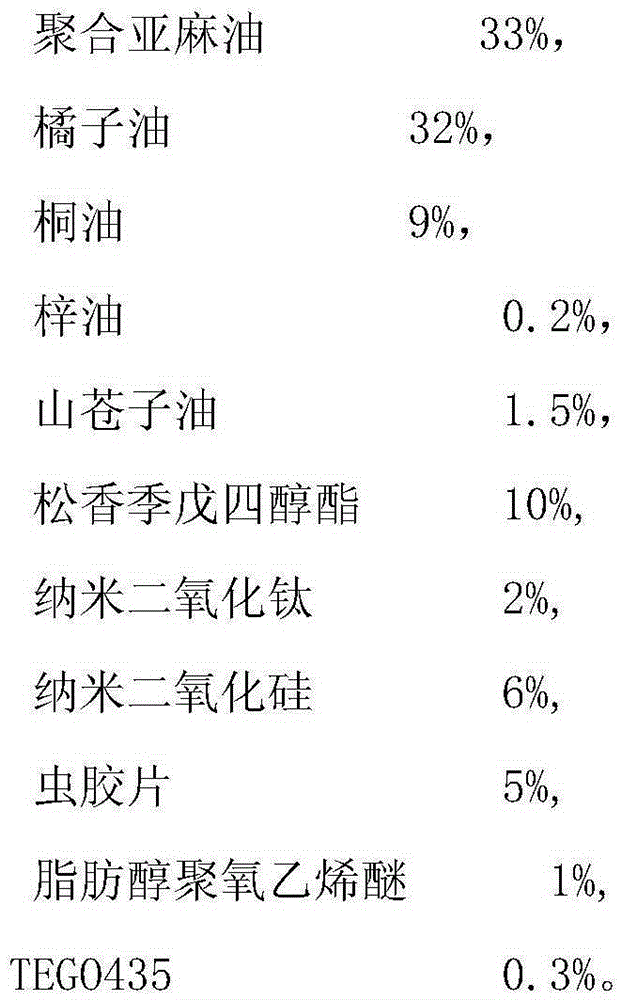

[0062] A coating oil for removing stains and maintaining furniture, comprising the following components by weight ratio:

[0063]

[0064] The preparation method of the above-mentioned coating oil for removing stains and maintaining furniture comprises the following steps:

[0065](1) Clean the dispersion cylinder with alcohol, dry it, put polymerized linseed oil, tung oil, rosin pentaerythritol ester, nano-titanium dioxide, shellac, catalpa oil, litsea cubeba oil, fatty alcohol polyoxyethylene ether, TEGO435 into the dispersion cylinder to disperse , the speed is 800RMP, and the time is 30min;

[0066] (2) Slowly add cold-pressed orange oil to the mixture treated in step (1), measure the viscosity with Tu-4 cup, adjust the viscosity to 10s, and obtain a semi-finished product;

[0067] (3) Slowly add nano silicon dioxide to the semi-finished product obtained through the treatment in step (2), stir and disperse until it becomes gel, and obtain the finished product;

[0068...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com