Gloss oil for historic building materials and preparation method thereof

A technology for ancient architecture and varnish, which is applied to the varnish of ancient building materials and the field of preparation thereof, can solve the problems of low degree of maturation, uneven heating, simple composition and the like of tung oil, so as to improve the performance of sterilization and UV resistance, and improve the gloss. and the effect of hardness, increasing surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The varnish used for ancient building materials is made from the following raw materials in parts by weight: 55 parts of raw tung oil, 10 parts of moringa seed oil, 10 parts of linseed oil, 5 parts of catalpa oil and 30 parts of rosin.

[0039] The preparation method of the varnish of present embodiment 1 may further comprise the steps:

[0040] Step 1, prepare each raw material according to the varnish described in claim 1 or 2;

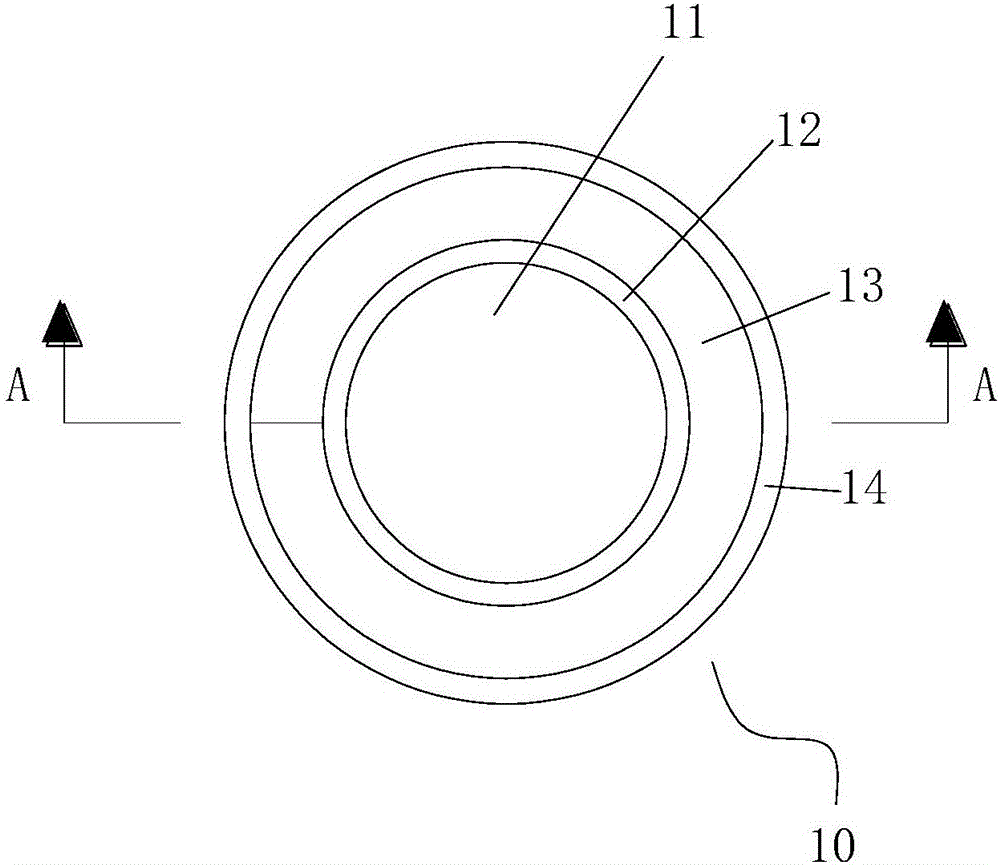

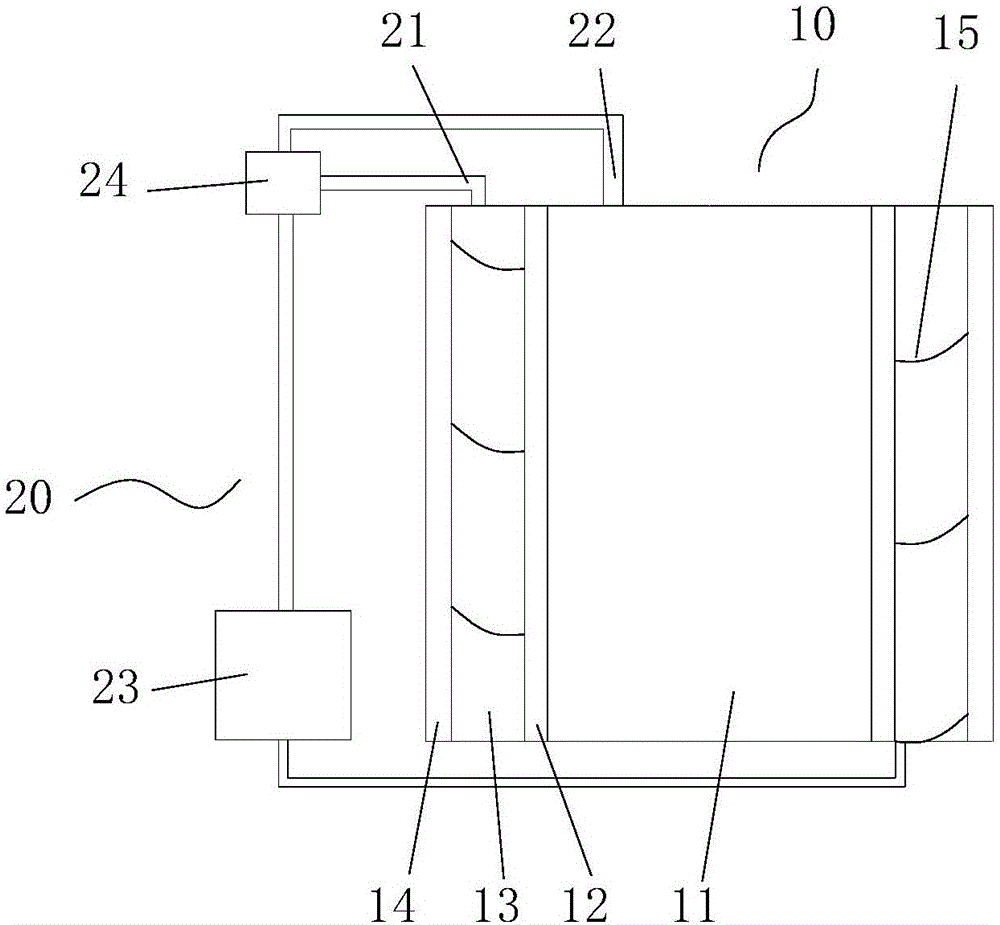

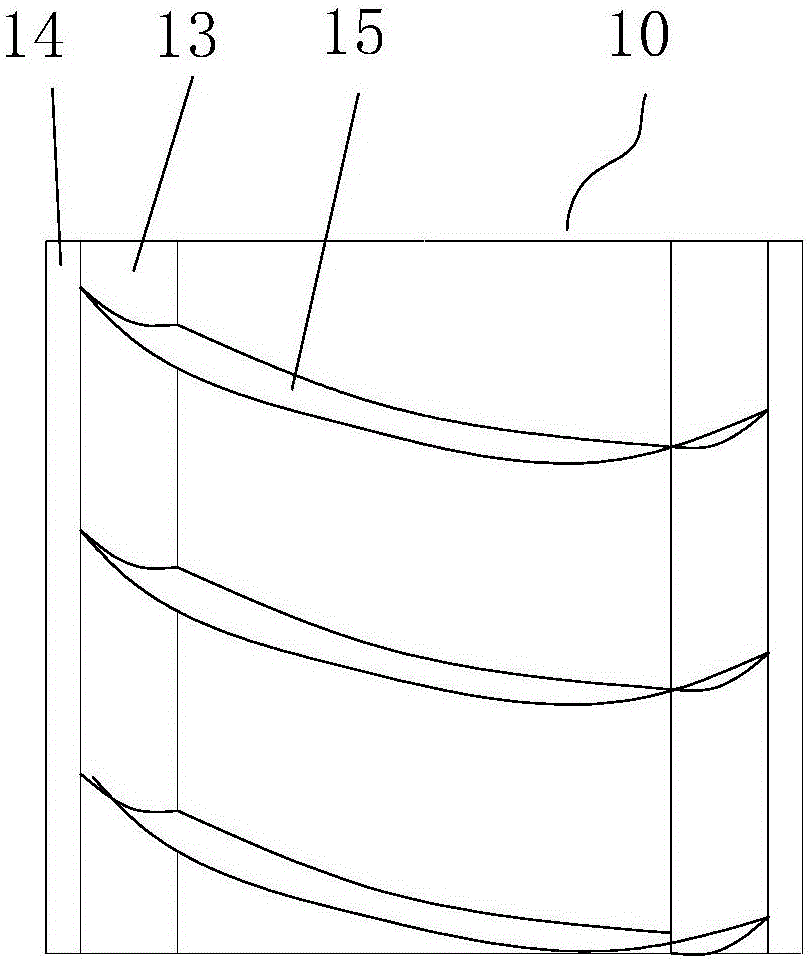

[0041] Step 2: Add raw tung oil into the reaction tank, heat to 180°C, keep warm, and keep the raw tung oil in an oxygen-enriched atmosphere during the heating and heat preservation process; then add the hot tung oil to Moringa seed oil, linseed oil and catalpa oil , mix well and heat up to 200°C, keep warm to get mixed vegetable oil;

[0042] Step 3. Add rosin to the mixed vegetable oil obtained in step 2. After the rosin is melted and mixed evenly, continue to heat up to 265°C and keep it warm for 2 hours. During the heat preservation proc...

Embodiment 2

[0044] The varnish used for ancient building materials is made from the following raw materials in parts by weight: 52 parts of raw tung oil, 5 parts of moringa seed oil, 5 parts of linseed oil, 3 parts of catalpa oil and 25 parts of rosin.

[0045] The preparation method of the varnish of this embodiment 2 is the same as the preparation method of embodiment 1.

Embodiment 3

[0047] The varnish used for ancient building materials is made from the following raw materials in parts by weight: 60 parts of raw tung oil, 15 parts of moringa seed oil, 15 parts of linseed oil, 8 parts of catalpa oil and 35 parts of rosin.

[0048] The preparation method of the varnish of the present embodiment 3 is the same as the preparation method of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com