High-barrier medicine packaging film and preparation method thereof

A high-resistance, diaphragm technology, applied in the field of pharmaceutical packaging, can solve the problems of changes in the barrier properties of pharmaceutical packaging films, unfavorable long-term storage of drugs, and easy deformation of composite packaging films, etc., to achieve excellent oxygen barrier and moisture resistance, good toughness, and avoid deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

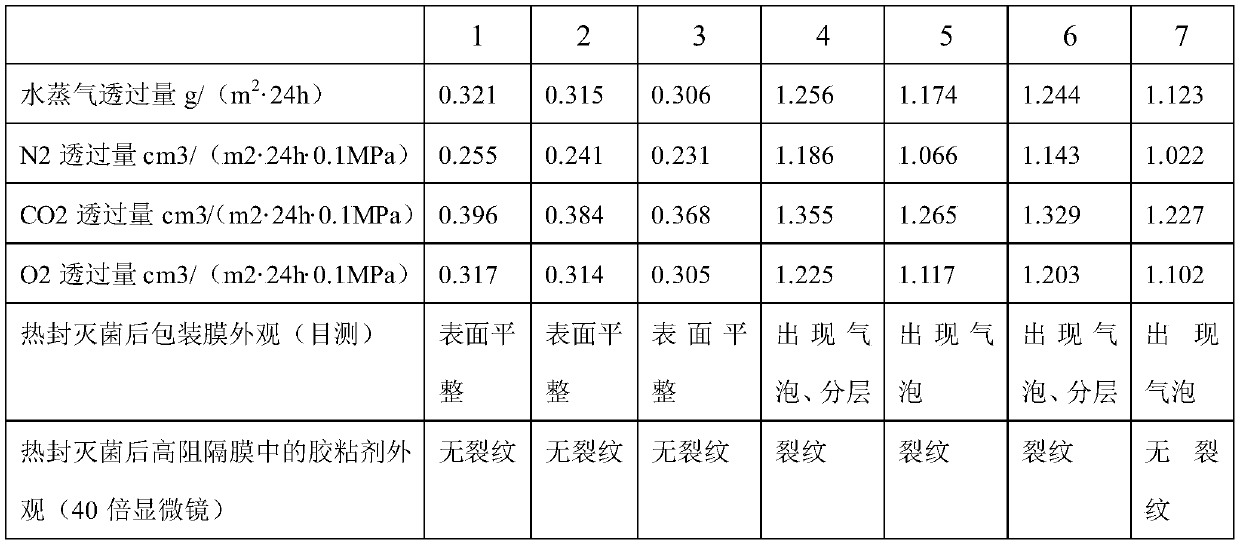

Examples

Embodiment 1

[0037] A high-barrier barrier film for pharmaceutical packaging of the present invention is prepared through the following process steps:

[0038] 1) Weigh 75 parts of polyvinylidene chloride, 8 parts of epoxy resin, 3 parts of nano-titanium dioxide, 8 parts of nano-alumina, 7 parts of carboxymethyl cellulose, 5 parts of graphene, 5 parts of plasticizer, coupling 2 parts of curing agent, 0.5 parts of curing agent, 5 parts of dibutyltin dilaurate for standby;

[0039] 2) Add dibutyltin dilaurate and plasticizer to polyvinylidene chloride latex, and stir at 1000r / min for 30min at 50°C;

[0040] 3) Nano-alumina and nano-titanium dioxide are mixed;

[0041]4) Add epoxy resin, carboxymethyl cellulose, nano-alumina and nano-titanium dioxide mixture, graphene, and coupling agent to the mixed solution obtained in step 2) in turn while stirring, and vacuum at 60°C at a speed of 3000r / min. Stir for 50min;

[0042] 5) Cool down to 35°C, add a curing agent, and stir in vacuum at a spee...

Embodiment 2

[0048] A high-barrier barrier film for pharmaceutical packaging of the present invention is prepared through the following process steps:

[0049] 1) Weigh 70 parts of polyvinylidene chloride, 12 parts of epoxy resin, 4 parts of nano-titanium dioxide, 6 parts of nano-alumina, 5 parts of carboxymethyl cellulose, 4 parts of graphene, 8 parts of plasticizer, coupling 4 parts of curing agent, 1.2 parts of curing agent, 8 parts of dibutyltin dilaurate for standby;

[0050] 2) Add dibutyltin dilaurate and plasticizer to polyvinylidene chloride latex, and stir at 1000r / min for 30min at 50°C;

[0051] 3) Nano-alumina and nano-titanium dioxide are mixed;

[0052] 4) Add epoxy resin, carboxymethyl cellulose, nano-alumina and nano-titanium dioxide mixture, graphene, and coupling agent to the mixed solution obtained in step 2) in turn while stirring, and vacuum at 60°C at a speed of 3000r / min. Stir for 50min;

[0053] 5) Cool down to 30°C, add a curing agent, and stir in vacuum at a sp...

Embodiment 3

[0059] A high-barrier barrier film for pharmaceutical packaging of the present invention is prepared through the following process steps:

[0060] 1) Weigh 73 parts of polyvinylidene chloride, 10 parts of epoxy resin, 3 parts of nano-titanium dioxide, 7 parts of nano-alumina, 6 parts of carboxymethyl cellulose, 5 parts of graphene, 7 parts of plasticizer, coupling 3 parts of curing agent, 0.8 parts of curing agent, 6 parts of dibutyltin dilaurate for standby;

[0061] 2) Add dibutyltin dilaurate and plasticizer to polyvinylidene chloride latex, and stir at 1000r / min for 30min at 50°C;

[0062] 3) Nano-alumina and nano-titanium dioxide are mixed;

[0063] 4) Add epoxy resin, carboxymethyl cellulose, nano-alumina and nano-titanium dioxide mixture, graphene, and coupling agent to the mixed solution obtained in step 2) in turn while stirring, and vacuum at 60°C at a speed of 3000r / min. Stir for 50min;

[0064] 5) Cool down to 35°C, add a curing agent, and stir in vacuum at a sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com