High polymer material for modifying explosive, and preparation method thereof, and method for modifying explosive

A technology of polymer materials and explosives, which can be used in non-explosive/non-thermal components, explosives, offensive equipment, etc., and can solve the problem of low stability of polymer materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

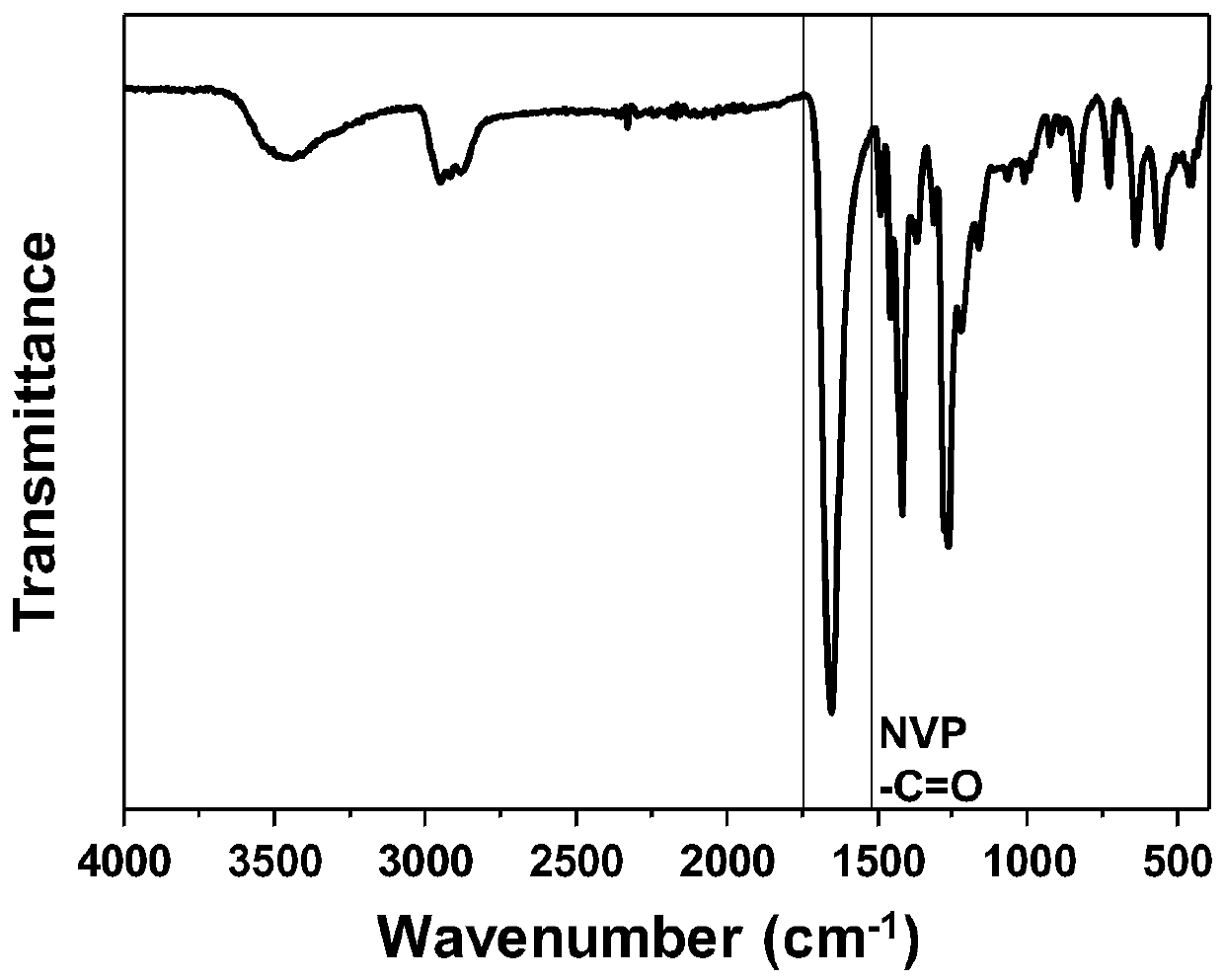

Embodiment 1

[0056] A kind of preparation method of the polymer material that is used for explosive modification, concretely carries out according to the following steps:

[0057] Step 1, weigh 95 parts of N-vinylpyrrolidone according to the mass fraction, and add it into a reaction vessel containing 145 parts of N,N-dimethylformamide to obtain N,N-dimethylformamide of N-vinylpyrrolidone Amide solution;

[0058] Step 2, add 0.24 parts of azobisisobutyronitrile according to the mass fraction to the raw material weighed in step 1, and mix uniformly;

[0059] In step 3, the mixed solution obtained in step 2 is deoxidized by bubbling argon gas for 10 minutes to obtain a deoxygenated mixed solution;

[0060] Step 4, heating the deoxidized mixed solution obtained in Step 3 to 70°C at a heating rate of 5°C / min, and keeping it at a constant temperature for 1 hour, and then naturally cooling to room temperature;

[0061] Step 5, rotary steaming for 30 minutes to remove N,N-dimethylformamide in th...

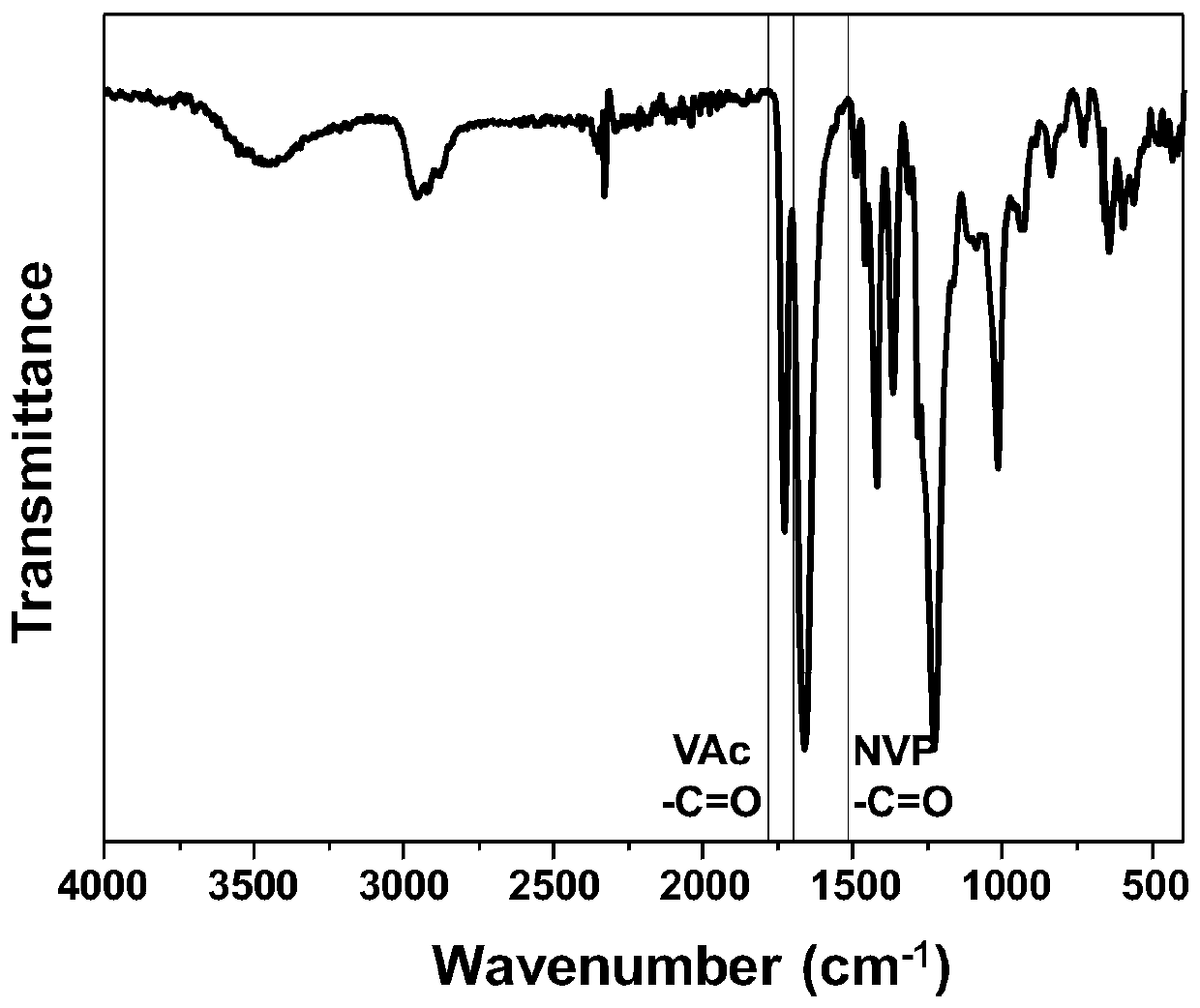

Embodiment 2

[0067] A kind of preparation method of the polymer material that is used for explosive modification, concretely carries out according to the following steps:

[0068] Step 1, weigh 45 parts of N-vinylpyrrolidone and 45 parts of vinyl acetate according to the mass fraction, and add them into a reaction vessel containing 210 parts of N,N-dimethylformamide to obtain N-vinylpyrrolidone and vinyl acetate N,N-dimethylformamide mixed solution of ester;

[0069] Step 2, add 1.5 parts of azobisisobutyronitrile to the mixed solution in step 1 according to the mass fraction, and mix well;

[0070] In step 3, the mixed solution obtained in step 2 is deoxidized by bubbling argon gas for 10 minutes to obtain a deoxygenated mixed solution;

[0071] Step 4, heating the deoxidized mixed solution obtained in Step 3 to 80°C at a heating rate of 5°C / min, and keeping it at a constant temperature for 12 hours, and then naturally cooling to room temperature;

[0072] Step five, rotary steaming for...

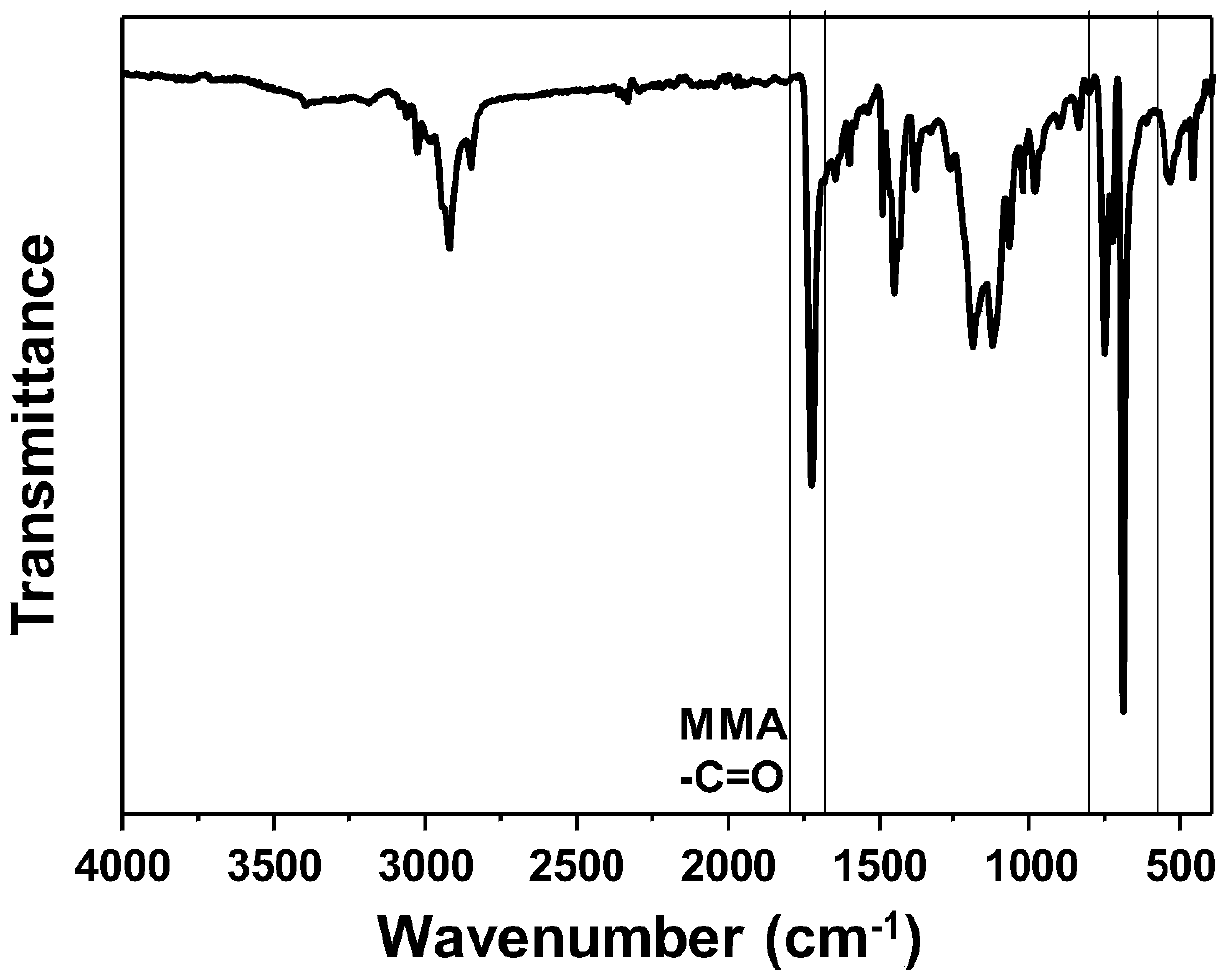

Embodiment 3

[0078] A kind of preparation method of the polymer material that is used for explosive modification, concretely carries out according to the following steps:

[0079] Step 1, take 1 part of N-vinylpyrrolidone, 49 parts of styrene, and 45 parts of methyl methacrylate, and add them to a reaction vessel containing 380 parts of N,N-dimethylformamide to obtain N-vinylpyrrolidone , N,N-dimethylformamide mixed solution of styrene and methyl methacrylate;

[0080] Step 2, add 4.7 parts of azobisisobutyronitrile to the mixed solution in step 1 according to the mass fraction, and mix well;

[0081] In step 3, the mixture obtained in step 2 is deoxidized by bubbling argon gas for 10 minutes to obtain a deoxidized mixture;

[0082] Step 4, heating the deoxidized mixture obtained in Step 3 to 90°C at a heating rate of 5°C / min, and keeping it at a constant temperature for 24h, and then naturally cooling to room temperature;

[0083] Step five, rotary steaming for 120 minutes to remove N,N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com