Preparation method of carbon-coated nano tin balls and products and application thereof

A nano-tin and carbon coating technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complex method, cumbersome process, high cost, achieve simple process, avoid agglomeration, Easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

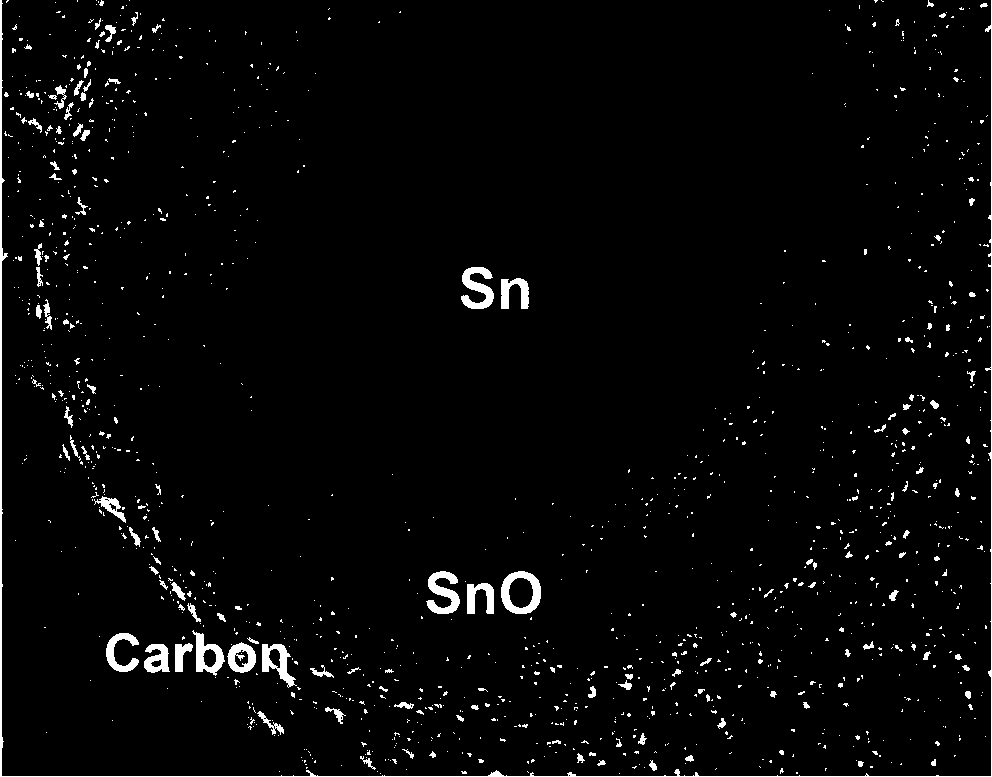

[0027] First, weigh 0.72 g of tin tetrachloride pentahydrate, dissolve it in 30 mL of deionized water, and stir for 30 minutes; then add 1.0 g of sodium oleate to the solution, and carry out ion exchange at 80°C for 6 hours to obtain Mixture of acid tin. Add 2.5 g of sodium carbonate crystals to the tin oleate mixture, and stir well until the tin oleate is evenly dispersed. The obtained tin oleate / sodium carbonate crystal material was placed in a tube furnace, raised to 700°C at a rate of 3°C / min under nitrogen protection, kept at 700°C for 6 hours, cooled naturally, and washed with deionized water , drying, and finally obtain the carbon-coated tin / stannous oxide nanosphere material. figure 1 It is the SEM picture of the tin / carbon composite material of this embodiment. It can be seen from the figure that it has a spherical structure with an average size of 10-25 nm; the outer layer of the tin ball is covered with a soft carbon layer. figure 2 It is the TEM image of the tin...

Embodiment 2

[0029] First, weigh 0.72 g of tin tetrachloride pentahydrate, dissolve it in 30 mL of deionized water, and stir for 30 minutes; then add 1.0 g of sodium oleate to the solution, and carry out ion exchange at 80°C for 6 hours to obtain Mixture of acid tin. Add 5.0 g of sodium carbonate crystals to the tin oleate mixture, and stir well until the tin oleate is evenly dispersed. The obtained tin oleate / sodium carbonate crystal material was placed in a tube furnace, raised to 700°C at a rate of 3°C / min under nitrogen protection, kept at 700°C for 6 hours, cooled naturally, and washed with deionized water , drying, and finally the carbon-coated tin / sn2 oxide nanosphere material can still be obtained.

Embodiment 3

[0031]First, weigh 0.72 g of tin tetrachloride pentahydrate, dissolve it in 30 mL of deionized water, and stir for 30 minutes; then add 1.0 g of sodium oleate to the solution, and carry out ion exchange at 80°C for 6 hours to obtain Mixture of acid tin. Add 5.0 g of sodium sulfate crystals to the tin oleate mixture, and stir well until the tin oleate is evenly dispersed. The obtained tin oleate / sodium sulfate crystal material was placed in a tube furnace, raised to 700°C at a rate of 3°C / min under nitrogen protection, kept at 700°C for 6 hours, cooled naturally, and washed with deionized water , drying, and finally carbon-coated tin / stannous oxide composites can still be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com