Graphene based epoxy waterproof and anti-corrosive potting slurry and preparation method thereof

A kind of epoxy and graphene technology, applied in epoxy resin glue, non-polymer adhesive additives, adhesive types and other directions, can solve the problems of decreased bonding performance, coagulation corrosion, anti-corrosion performance and other problems , to achieve the effect of maintaining adhesion and flexibility, effective waterproof and anti-corrosion, and avoiding brittle section cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Graphene epoxy waterproof and anti-corrosion potting slurry, including component A and component B, the mass ratio of component A and component B is 1:1.

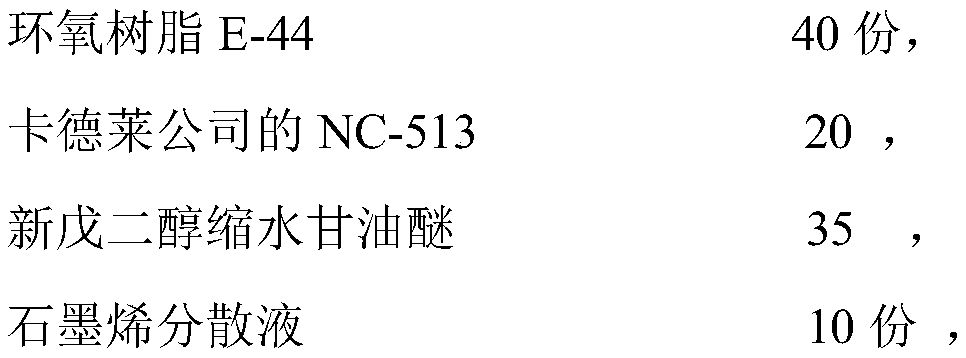

[0045] The A component is composed of the following components by mass,

[0046]

[0047] The solid content of the graphene dispersion is 10%, the thickness is 0.5-3.0nm, the diameter of the microchip is about 0.5-3μm, and the number of layers: 1-3 layers. It is a uniformly dispersed and stable graphene dispersion.

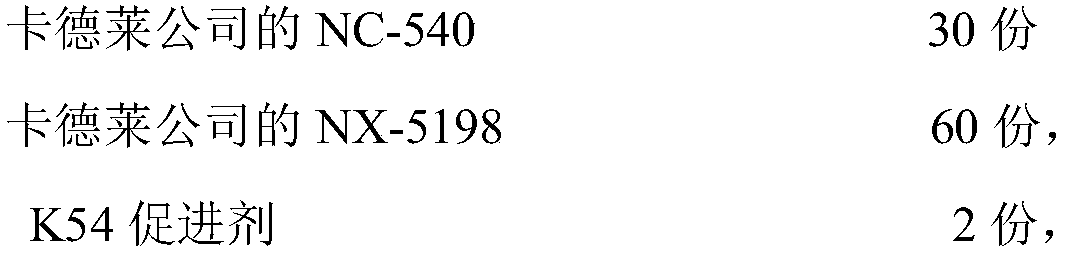

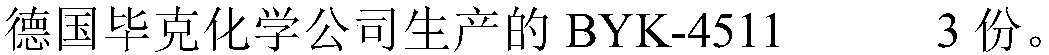

[0048] The B component is composed of the following components by mass:

[0049]

[0050]

Embodiment 2

[0052] Graphene epoxy waterproof and anti-corrosion potting slurry includes component A and component B, and the mass ratio of component A and component B is 1:1.5.

[0053] The A component is composed of the following components by mass,

[0054]

[0055]The graphene dispersion is a graphene isopropanol dispersion. Preferably, the dispersion is formed by adding a reducing agent and a dispersant to the graphene oxide dispersion. Further, the solid content of the graphene dispersion is 12%, the thickness is 0.5-3.0nm, the diameter of the microchip is about 0.5-3μm, and the number of layers: 1-3 layers. It is a uniformly dispersed and stable graphene dispersion.

[0056] The B component is composed of the following components by mass:

[0057]

Embodiment 3

[0059] Graphene epoxy waterproof and anti-corrosion potting slurry, including component A and component B, the mass ratio of component A and component B is 1:1.

[0060] The A component is composed of the following components by mass,

[0061]

[0062] The graphene dispersion is a graphene isopropanol dispersion. Preferably, the dispersion is formed by adding a reducing agent and a dispersant to the graphene oxide dispersion. Further, the solid content of the graphene dispersion is 15%, the thickness is 0.5-3.0nm, the diameter of the microchip is about 0.5-3 μm, and the number of layers: 1-3 layers. It is a uniformly dispersed and stable graphene dispersion.

[0063] The B component is composed of the following components by mass:

[0064]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com