Foamed nickel/MXene-Co3O4 composite electrode and preparation method thereof

A composite electrode and nickel foam technology, which is applied in the field of electrochemistry, can solve problems such as limiting large-scale applications, and achieve the effects of improving activity and stability, improving electrical conductivity, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

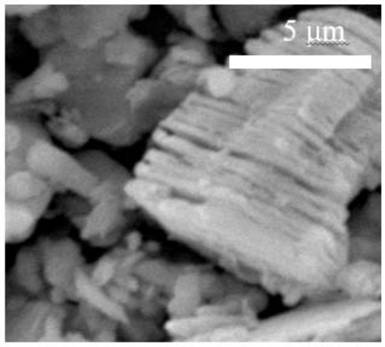

[0033] Nickel foam was taken, ultrasonically cleaned three times with sulfuric acid, ethanol, and deionized water in sequence, and dried in a constant temperature oven at a temperature of 50 °C for 1 h; MXene, Co 3 o 4 Mix and oscillate with a vortex oscillator for 2 minutes to prepare mixed powder, apply it evenly on the surface of nickel foam, and vacuum plasma sinter. Composite electrode;

[0034] The nickel foam has a diameter of 2 cm, a pore size of 100 μm, and a thickness of 3 mm; MXene and Co 3 o 4 The mass ratio is 1:6, the mass of the mixed powder is 0.05g, Co 3 o 4 The average particle size is 20nm.

Embodiment 2

[0036] Nickel foam was ultrasonically cleaned twice with sulfuric acid, ethanol, and deionized water in sequence, and dried in a constant temperature oven at 50 °C for 1.2 h; MXene, Co 3 o 4 Mix and oscillate with a vortex oscillator for 2 minutes to prepare mixed powder, evenly spread on the surface of nickel foam, and vacuum plasma sintering. composite electrode;

[0037] The nickel foam has a diameter of 3 cm, a pore size of 200 μm, and a thickness of 3.5 mm; MXene and Co 3 o 4 The mass ratio is 1:5, the mass of the mixed powder is 0.07g, Co 3 o 4 The average particle size is 80nm.

Embodiment 3

[0039] Nickel foam was ultrasonically cleaned three times with sulfuric acid, ethanol, and deionized water in sequence, and dried in a constant temperature oven at 50 °C for 1.5 h; MXene, Co 3 o 4 Mix and oscillate with a vortex oscillator for 4 minutes to obtain a mixed powder, which is evenly spread on the surface of nickel foam and vacuum plasma sintered. The sintering process is: vacuum 55Pa, sintering temperature is 600°C, applied pressure is 2MPa, and the sintering time is 15min. Composite electrode;

[0040] The nickel foam has a diameter of 2.5 cm, a pore size of 150 μm, and a thickness of 4 mm; MXene and Co 3 o 4 The quality of the mixed powder is 0.1g when the mass ratio is 1:4, Co 3 o 4 The average particle size is 50nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com