Preparation method of composite material containing lactobionic acid-modified graphene oxide

A composite material and graphene technology, which is applied in the field of preparation of graphene oxide composite materials, can solve the problems of increasing cytotoxicity, achieve mild experimental conditions, simple operation, and overcome the effect of easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

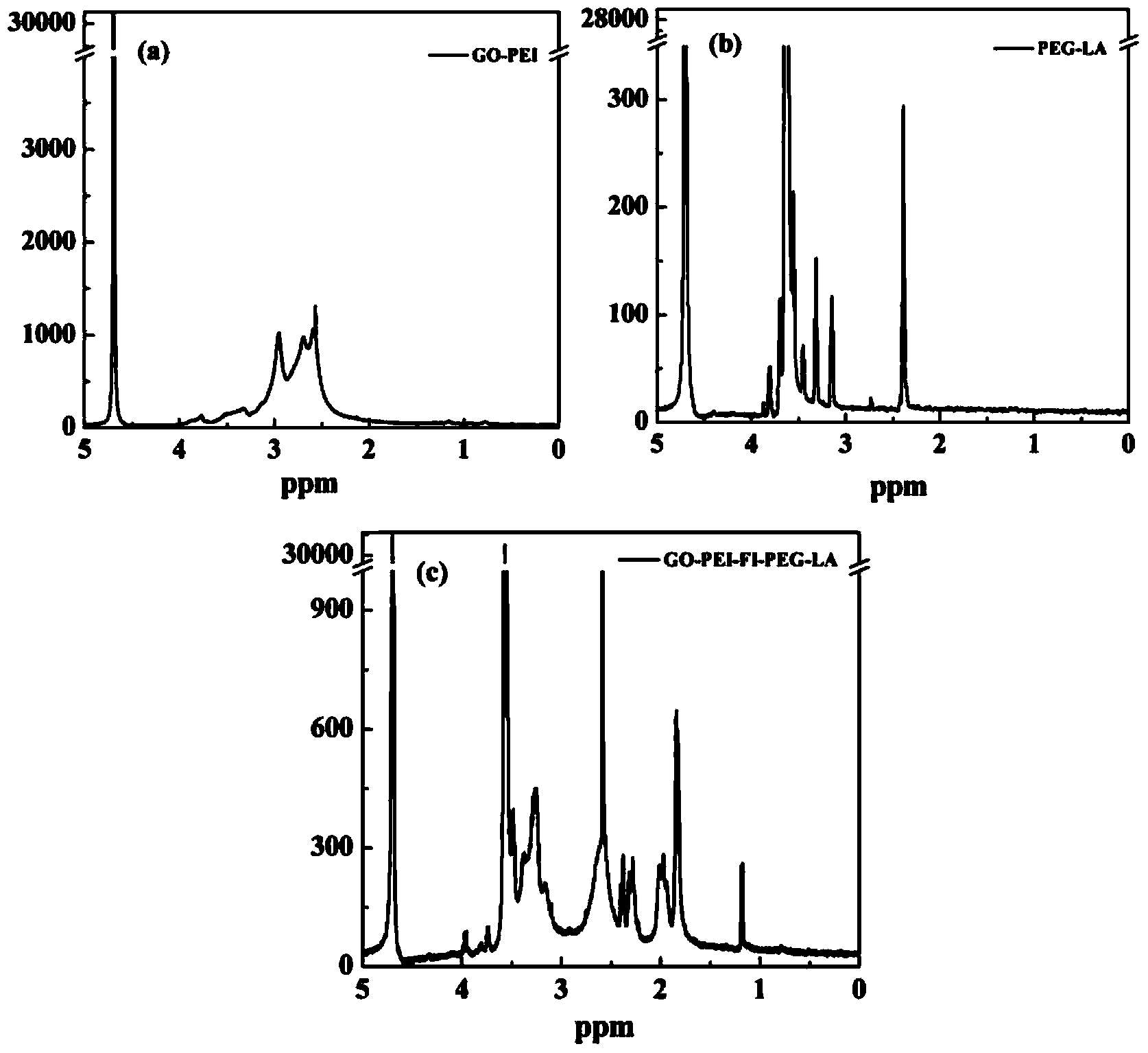

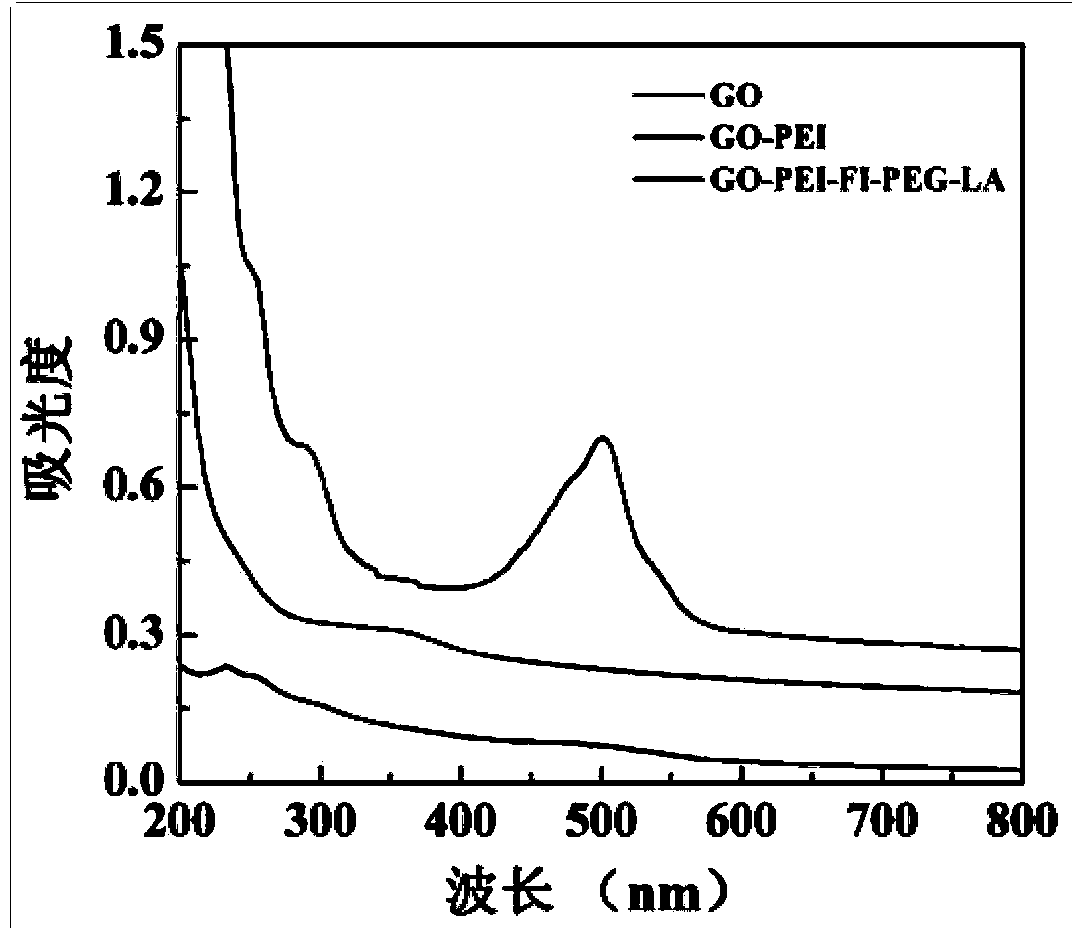

[0033] (1) Dissolve GO (344.9mg) in 40mL DMSO, then add EDC (354.32mg) to activate and stir for 3h. While stirring, 10 mL of DMSO solution containing PEI (540.01 mg) was added dropwise, and the reaction was stirred ultrasonically at room temperature for 24 h. Finally, the reaction solution was put into a dialysis bag (MW=100,000), and unreacted impurities and by-products were removed by dialysis. Firstly, it was dialyzed twice with PBS buffer, 2 L each time, and then dialyzed seven times with distilled water. Finally, the product was freeze-dried to obtain GO-PEI.

[0034] (2) Weigh 100 mg LA, add 35 mg EDC and 21 mg NHS to phosphate buffer to activate for three hours, add 400 mg NH2-mPEG-COOH, stir for 24 hours, and finally put the reaction solution into a dialysis bag (MW=1,000), and use dialysis to remove the unreacted To remove impurities and by-products, dialyze twice with PBS buffer, 2L each time, and then dialyze seven times with distilled water. Finally the product i...

Embodiment 2

[0038] (1) Dissolve GO (300mg) in 30mL DMSO, then add EDC (304mg) to activate and stir for 3h. While stirring, 10 mL of DMSO solution containing PEI (452.3 mg) was added dropwise, and the reaction was stirred ultrasonically at room temperature for 24 h. Finally, the reaction solution was put into a dialysis bag (MW=100,000), and unreacted impurities and by-products were removed by dialysis. Firstly, it was dialyzed twice with PBS buffer, 2 L each time, and then dialyzed seven times with distilled water. Finally, the product was freeze-dried to obtain GO-PEI.

[0039] (2) Weigh 23 mg LA, add 8.01 mg EDC and 4.8 mg NHS to phosphate buffer to activate for three hours, add 100 mg NH2-mPEG-COOH, stir for 24 hours, and finally put the reaction solution into a dialysis bag (MW=1,000), and use dialysis to dissolve To remove unreacted impurities and by-products, dialyze twice with PBS buffer, 2 L each time, and then dialyze seven times with distilled water. Finally the product is fre...

Embodiment 3

[0043] (1) Dissolve GO (50mg) in 10mL DMSO, then add EDC (33mg) to activate and stir for 3h. With stirring, 10 mL of DMSO solution containing PEI (75 mg) was added dropwise, and the reaction was stirred ultrasonically at room temperature for 24 h. Finally, the reaction solution was put into a dialysis bag (MW=100,000), and unreacted impurities and by-products were removed by dialysis. Firstly, it was dialyzed twice with PBS buffer, 2 L each time, and then dialyzed seven times with distilled water. Finally, the product was freeze-dried to obtain GO-PEI.

[0044] (2) Weigh 44 mg LA, add 21 mg EDC and 11 mg NHS to phosphate buffer to activate for three hours, add 180 mg NH2-mPEG-COOH, stir for 24 hours, and finally put the reaction solution into a dialysis bag (MW=1,000), and use dialysis to remove the unreacted To remove impurities and by-products, dialyze twice with PBS buffer, 2L each time, and then dialyze seven times with distilled water. Finally the product is freeze-drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com