Preparation method of iron phthalocyanine/activated carbon Li/SOCl2 battery positive electrode catalytic material

A battery positive electrode and catalytic material technology, which is applied in battery electrodes, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of short synthesis cycle, good dispersion, and high purity, and achieve short synthesis cycle, easy process control, and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

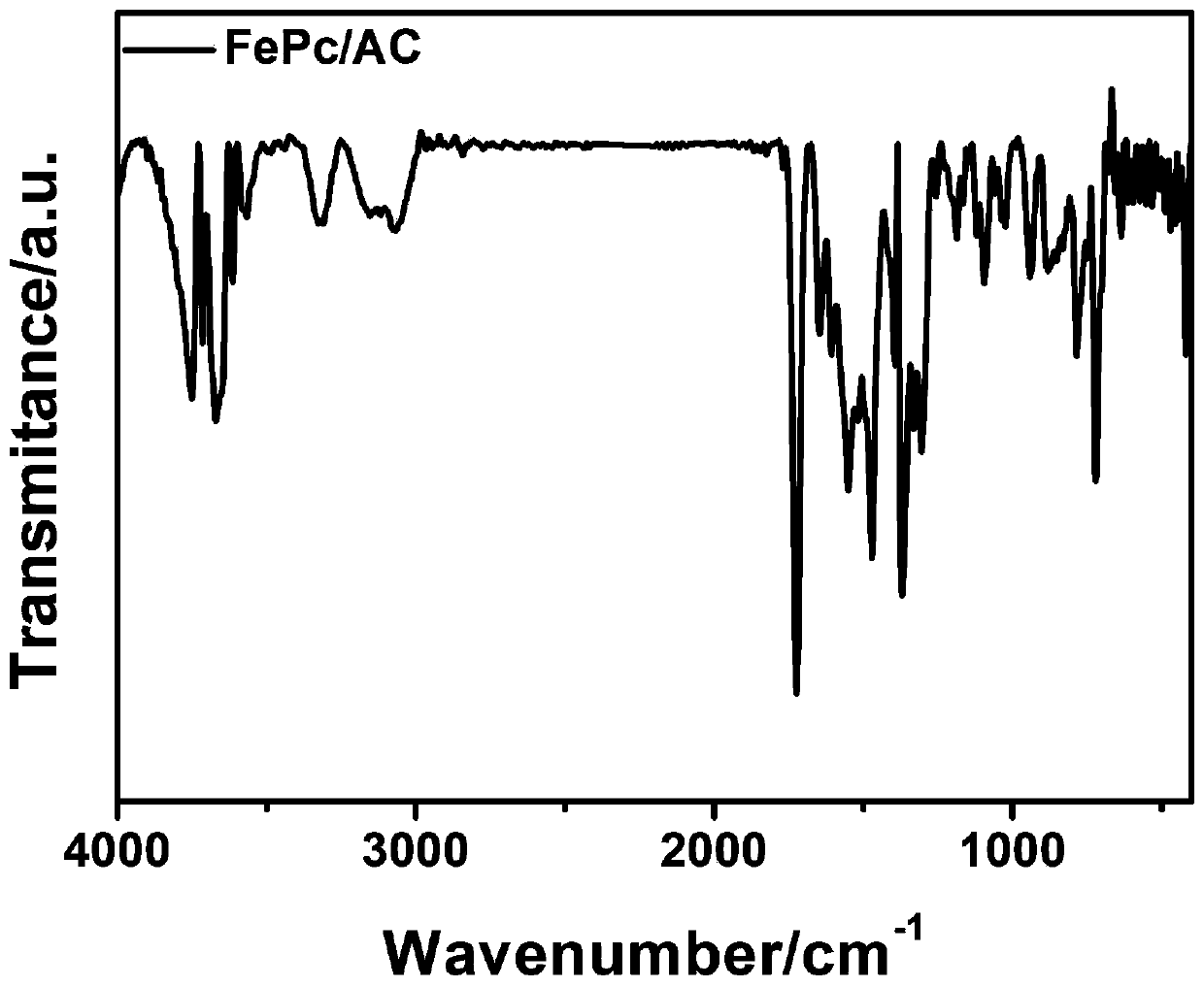

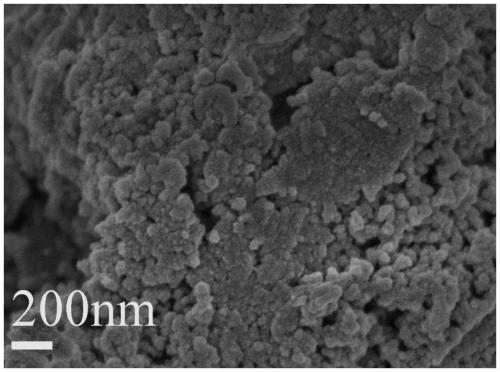

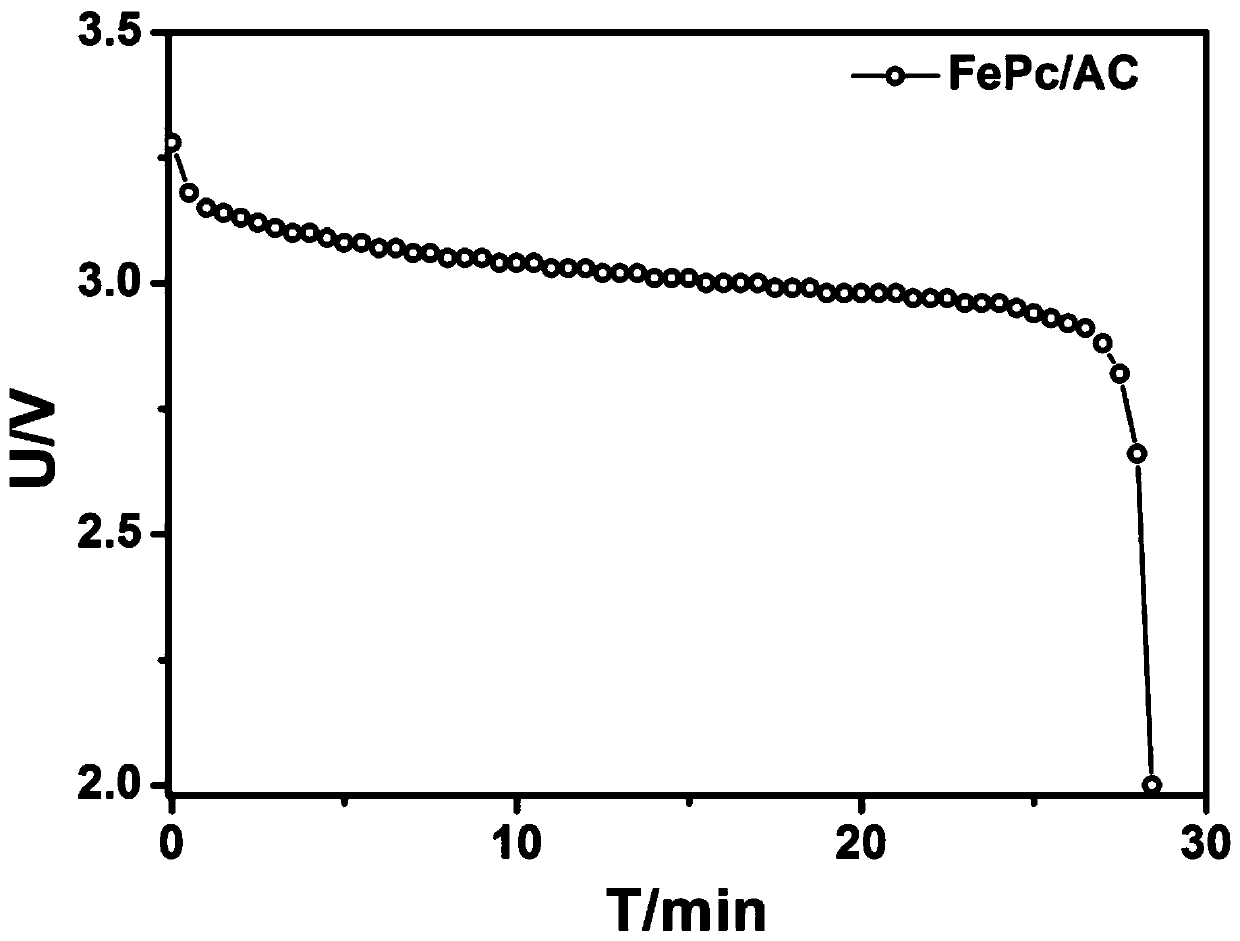

[0023] A kind of iron phthalocyanine / activated carbon Li / SOCl 2 A method for preparing a positive electrode catalyst material for a battery, comprising the following steps:

[0024] Step 1: Take 0.819g of phthalic anhydride and 0.1g of specific surface area of 1400m 2 / g of pitch coke activated carbon is placed in a glass mortar and mixed evenly to obtain a mixture;

[0025] Step 2: Put 0.6g of urea, 0.03g of ammonium molybdate and 0.5g of ferrous ammonium sulfate hexahydrate into a glass mortar and mix them with the mixture and grind them thoroughly, then put them into a ceramic crucible and place them in a muffle In the furnace, the temperature was raised from room temperature to 120°C at a heating rate of 10°C / min and kept for 0.5h; then the temperature was raised to 140°C at a heating rate of 5°C / min and kept for 0.1h; Sinter at 250°C and hold for 2 hours to obtain a sintered product;

[0026] Step 3: Cool to room temperature, soak the sintered product with deionized ...

Embodiment 2

[0028] A kind of iron phthalocyanine / activated carbon Li / SOCl 2 A method for preparing a positive electrode catalyst material for a battery, comprising the following steps:

[0029] Step 1: Take 0.819g of phthalic anhydride and 0.1g of specific surface area of 1400m 2 / g of pitch coke activated carbon is placed in a glass mortar and mixed evenly to obtain a mixture;

[0030] Step 2: Put 1.2g of urea, 0.12g of ammonium molybdate and 1g of ferrous ammonium sulfate hexahydrate into a glass mortar and mix them with the mixture and grind them thoroughly, then put them into a ceramic crucible and place them in a muffle furnace From room temperature to 120°C at a rate of 10°C / min and hold for 0.2h; then at a rate of 10°C / min to 130°C and hold for 0.1h; then at a rate of 10°C / min to 270 ℃ and keep it warm for 2h for sintering to obtain a sintered product;

[0031] Step 3: Cool to room temperature, soak the sintered product with deionized water for 12 hours each time, and change t...

Embodiment 3

[0036] A kind of iron phthalocyanine / activated carbon Li / SOCl 2 A method for preparing a positive electrode catalyst material for a battery, comprising the following steps:

[0037] Step 1: Take 0.41g of phthalic anhydride and 0.05g of specific surface area of 1400m 2 / g of pitch coke activated carbon is placed in a glass mortar and mixed evenly to obtain a mixture;

[0038] Step 2: Put 0.6g of urea, 0.03g of ammonium molybdate and 0.8g of ferrous ammonium sulfate hexahydrate into a glass mortar and mix them with the mixture and grind them thoroughly, then put them into a ceramic crucible and place them in a muffle In the furnace, the temperature was raised from room temperature to 125°C at a heating rate of 5°C / min and kept for 0.5h; then the temperature was raised to 150°C at a heating rate of 10°C / min and kept for 0.1h; Sinter at 260°C and hold for 1.5h to obtain a sintered product;

[0039] Step 3: Cool to room temperature, soak the sintered product with deionized wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com