High-dispersity indium oxide and preparation method thereof

A high-dispersion, indium oxide technology, applied in chemical instruments and methods, inorganic chemistry, gallium/indium/thallium compounds, etc., can solve problems such as difficult to form large-scale production, achieve high-dispersion crystal structure, overcome easy agglomeration , the effect of uniform size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

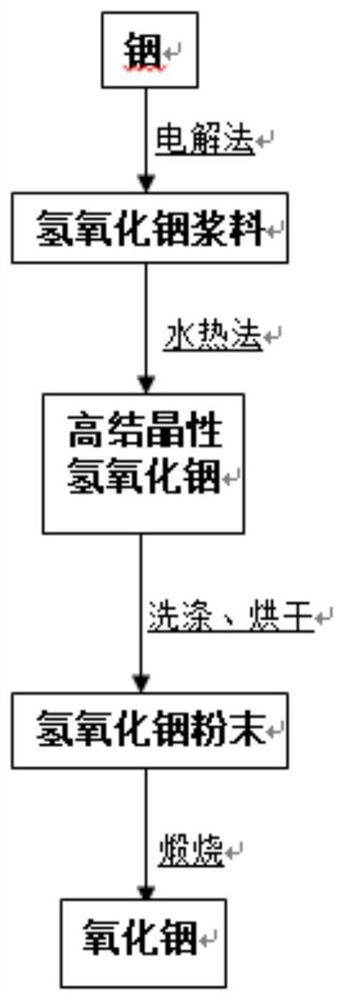

[0025] The invention provides a method for preparing highly dispersible indium oxide, comprising the following steps:

[0026] a) using metal indium as an anode, an inert electrode as a cathode, and an ammonium nitrate aqueous solution as an electrolyte, and obtaining an indium hydroxide slurry by electrolysis;

[0027] b) Add indium nitrate solution to the indium hydroxide slurry obtained in step a), so that the mass ratio of the added indium ions to indium hydroxide is 0.01% to 1%, and after adjusting the pH value to 4 to 8, carry out water Thermal reaction, the product is washed and dried to obtain highly crystalline and highly dispersible indium hydroxide powder;

[0028] c) Calcining the highly crystalline and highly dispersible indium hydroxide powder obtained in step b) to obtain highly dispersible indium oxide.

[0029] In the present invention, the indium hydroxide slurry is firstly obtained by an electrolysis method by using metal indium as an anode, an inert electr...

Embodiment 1

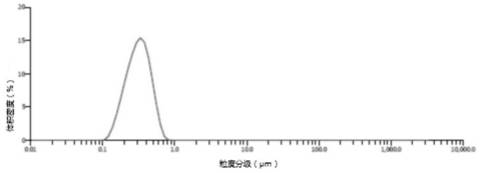

[0048] (1) Prepare indium hydroxide slurry with D50 less than 1 μm by electrolysis. In the electrolysis method of this embodiment, the anode and the cathode are installed in an electrolysis chamber at the same time. Ammonium nitrate aqueous solution with a concentration of 2.8mol / L, then heat the electrolytic chamber to 65°C, turn on the power, and set the current density to 500A / m 2 , and continued electrolysis for 15 hours to obtain a slurry with a D50 of less than 1 μm.

[0049] (2) Using centrifugal sedimentation, separate an appropriate amount of supernatant from the slurry obtained in step (1), prepare it to a concentration of about 100g / L, pour it into a hydrothermal reaction kettle, add indium nitrate solution to make the The mass ratio of indium ions to indium hydroxide is 0.5%, and dilute nitric acid is used to adjust the pH value to 4; then hydrothermal reaction is carried out at 200°C for 24h, and then washed, centrifugal spray-dried (temperature 150°C, atomizatio...

Embodiment 2

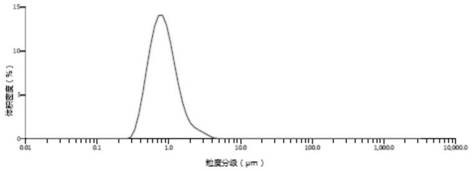

[0053] (1) Prepare indium hydroxide slurry with D50 less than 1 μm by electrolysis. In the electrolysis method of this embodiment, the anode and the cathode are installed in an electrolysis chamber at the same time. Ammonium nitrate aqueous solution with a concentration of 2.8mol / L, then heat the electrolytic chamber to 65°C, turn on the power, and set the current density to 500A / m 2 , and continued electrolysis for 15 hours to obtain a slurry with a D50 of less than 1 μm.

[0054] (2) Using centrifugal sedimentation, separate an appropriate amount of supernatant from the slurry obtained in step (1), prepare it to a concentration of about 100g / L, pour it into a hydrothermal reaction kettle, add indium nitrate solution to make the The mass ratio of indium ions to indium hydroxide is 0.05%, and the pH value is adjusted to 6.5 with nitric acid; then hydrothermal reaction is carried out at 200°C for 24h, and then washed and centrifugally spray-dried (temperature 150°C, atomizing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com