Patents

Literature

46results about How to "Conducive to stable production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Base material for artificial leather and process for producing the same

ActiveUS20110039055A1Improve compactnessFlat surfaceSynthetic resin layered productsFilament/thread formingFiber bundleEngineering

Owner:KURARAY CO LTD

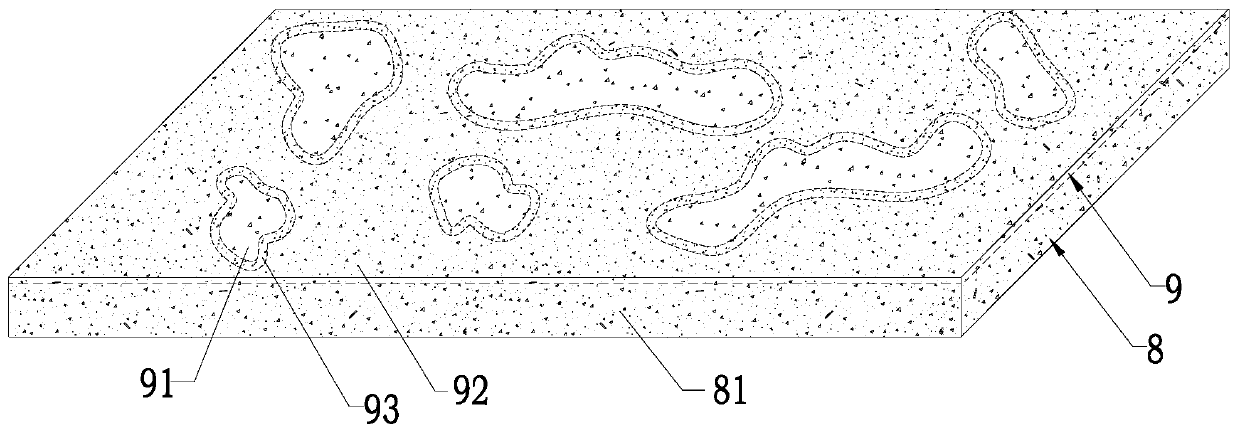

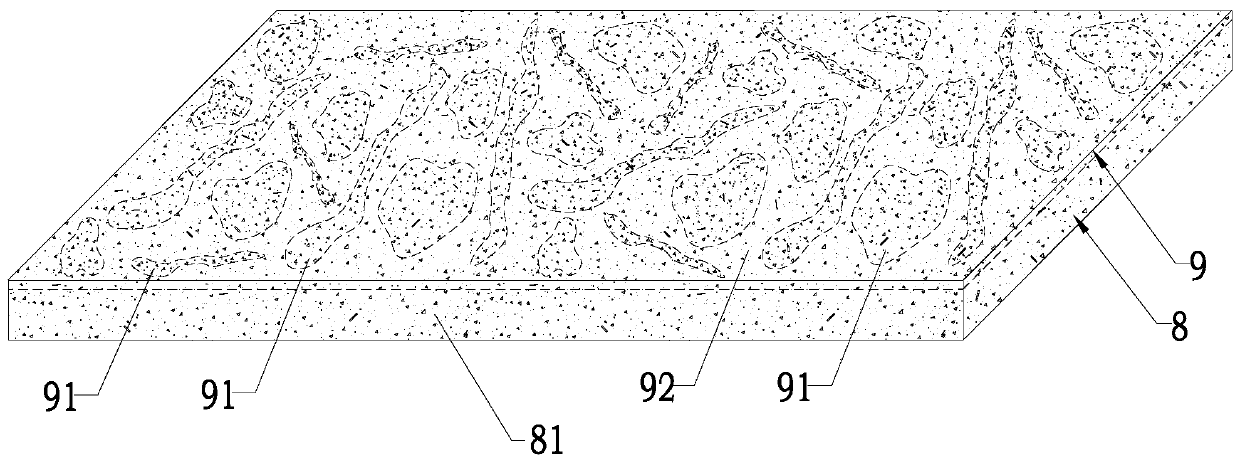

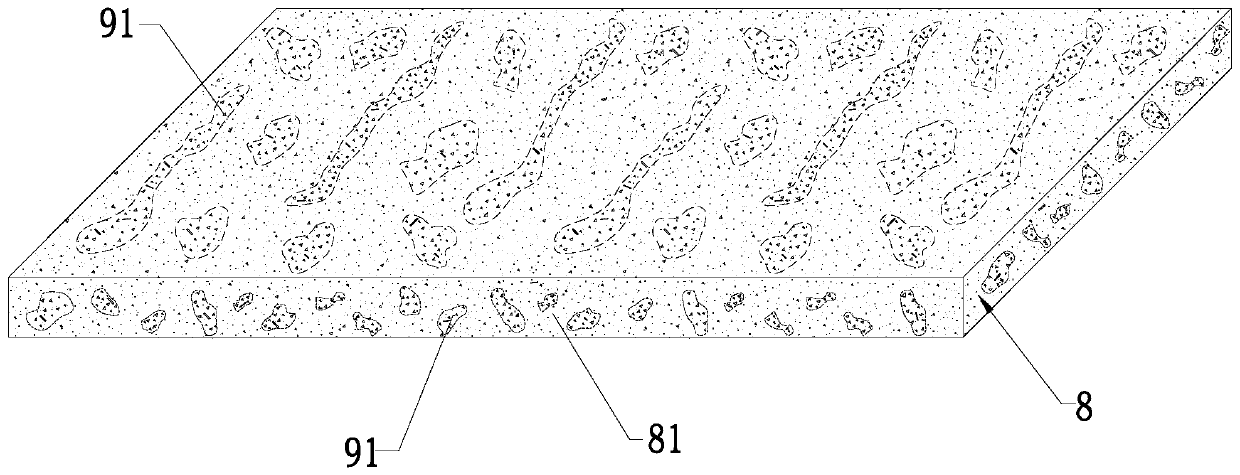

Porcelain plate containing green body texture and manufacturing method of porcelain plate

InactiveCN110103319AGood consistencyMore consistent colorsCovering/liningsFeeding arrangmentsControllabilityGreen body

The invention discloses a porcelain plate containing green body texture and a manufacturing method of the porcelain plate. The porcelain plate comprises a main body layer and a texture layer; the manufacturing method comprises the steps of material preparing, main body layer material distributing, texture layer material distributing, raw material uniform distributing, pressing, drying, sintering,edging or polishing; during texture layer material distributing, texture molding of a green body can be completed fast and efficiently through a carving type roller or a carving belt, or a special-shaped guiding material distributing device provided with a guiding material distributing plate is used, under the action of the guiding material distributing plate, the fluidity is different due to thefact that the particle sizes of flaky materials, granular materials and powdery raw materials are different, so that texture raw materials in a texture color zone form a texture layout with differentand changed accumulation forms. The method is suitable for large plate production, and compared with a traditional material distributing mode, the method has the advantages of being small in occupiedspace, simple in equipment structure and high in controllability.

Owner:GUANGDONG SUMMIT CERAMIC CO LTD +1

Rehabilitation new dispersing tablet and preparation method thereof

InactiveCN101564402AFast absorptionConducive to stable productionAnthropod material medical ingredientsDigestive systemPhysical medicine and rehabilitationPhysical therapy

The invention discloses a rehabilitation new dispersing tablet used for treating digestive system diseases and a preparation method thereof. The rehabilitation new dispersing tablet is prepared from a major material, namely 10 to 55 weight percent of rehabilitation new dry extract powder, and accessories comprising a disintegrant, a filling agent, a wetting agent and a lubricant through granulation and tabletting by a wet method, wherein the disintegrant can be added internally or externally or internally and externally. Compared with the prior solution, the rehabilitation new dispersing tablet has the advantages of good dispersing state, short disintegration time, quick medicament dissolution, convenient taking, low production cost, no need of special equipment, easy mass production, convenient carrying and transportation, stability and the like.

Owner:EASTERN LIAONING UNIV

Titanium oxide-titanium carbide whisker toughened magnesium alloy biomedical material

The invention belongs to the field of biomedical materials and particularly relates to a titanium oxide-titanium carbide whisker toughened magnesium alloy biomedical material. The titanium oxide-titanium carbide whisker toughened magnesium alloy biomedical material is composed of magnesium alloy substrate material powder and titanium oxide-titanium carbide whisker powder; the magnesium alloy substrate material powder and the titanium oxide-titanium carbide whisker powder are uniformly mixed through a mechanical mixing method; the mixed powder is subjected to cold pressing, vacuum heating degassing and vacuum sintering; and a heat pressing ingot is subjected to equal channel deformation, so that the titanium oxide-titanium carbide whisker toughened magnesium alloy biomedical material is obtained. The toughness, the abrasion resistance and the strength of in-situ generated titanium oxide-titanium carbide whisker toughened magnesium alloy are remarkably improved, and the in-situ generated titanium oxide-titanium carbide whisker toughened magnesium alloy is especially suitable for the biomedical material and also can be applied to parts such as high-end sports car magnesium alloy hubs requiring for high strength and high abrasion resistance.

Owner:SHANDONG JIANZHU UNIV

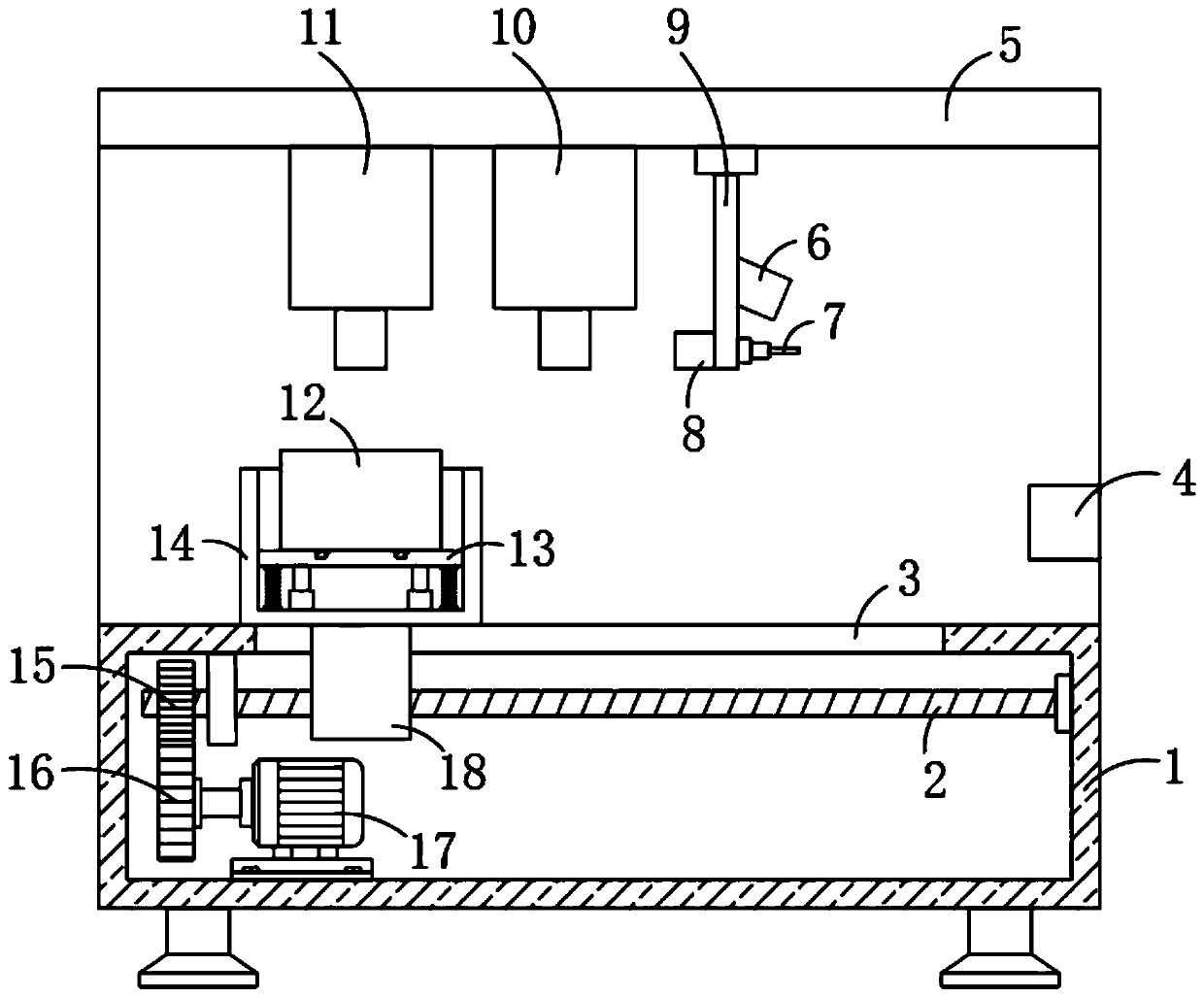

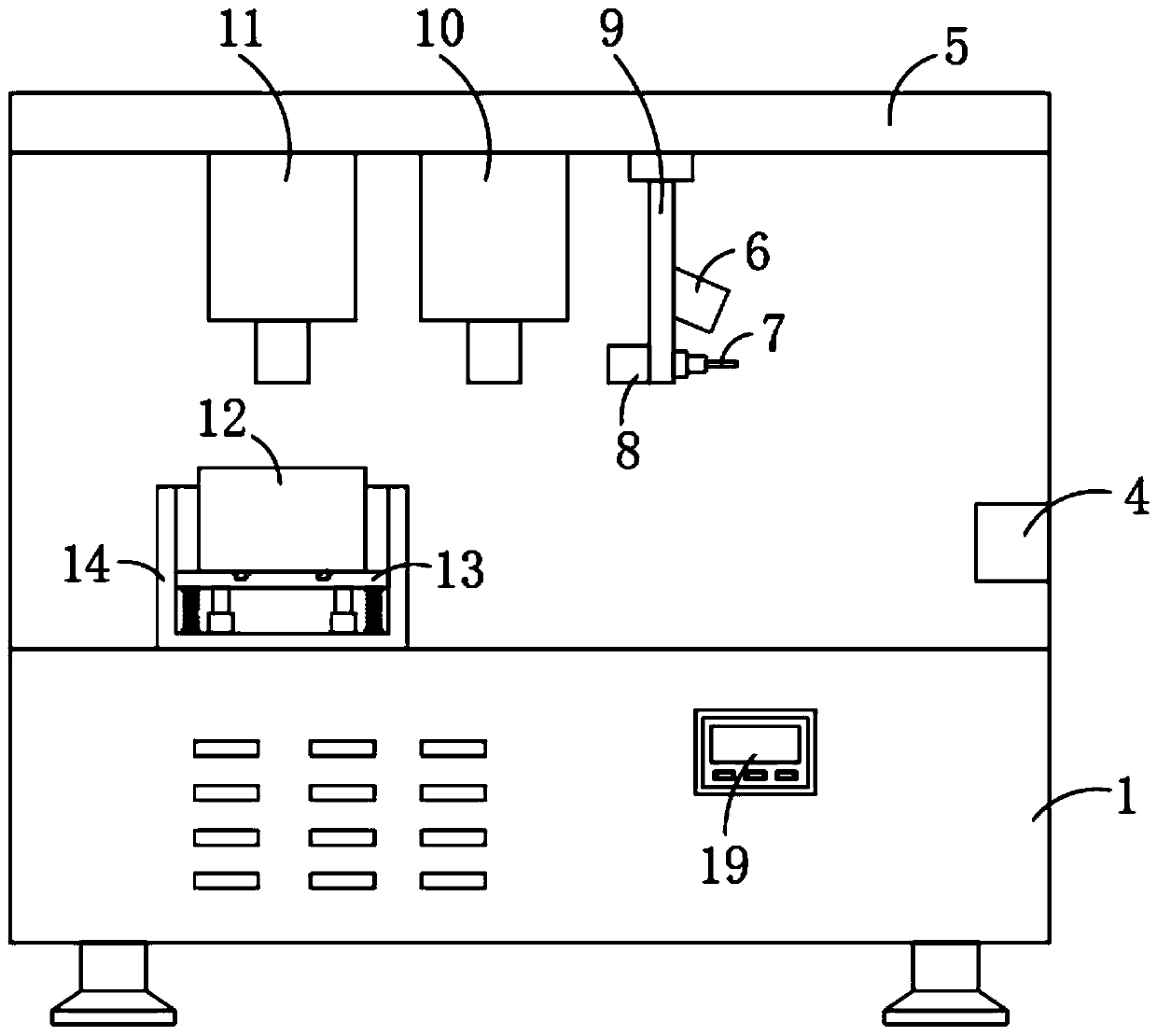

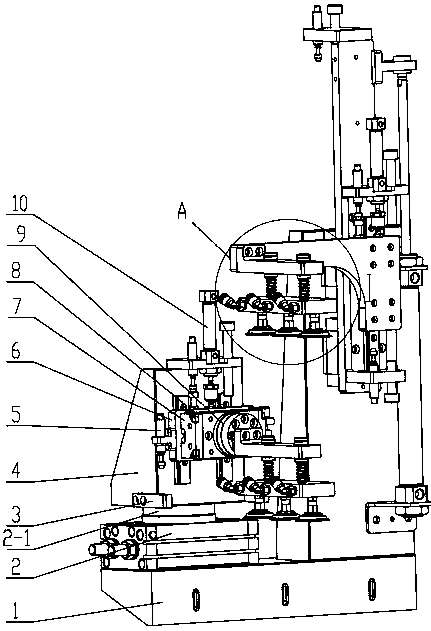

Bubble water toy processing blow molding production device

InactiveCN111055442AEnable mobilityAchieve liftingMetal working apparatusBlow moldingProcess engineering

The invention discloses a bubble water toy processing blow molding production device, and relates to the technical field of bubble water toy production device. The bubble water toy processing blow molding production device comprises a machine body, wherein a fixing frame is mounted at the top of the machine body, the top of the fixing frame is sequentially and fixedly provided with an injection molding machine, an inflator and a fixing rod from left to right, an electric push rod is mounted at the bottom end of the fixing rod, the telescopic end of the electric push rod is connected with a cutting knife, a lead screw is movably mounted at the upper part of the interior of the machine body through a bearing, the outer part of the lead screw is sleeved with a moving sleeve rod, and the top of the moving sleeve rod is provided with a moving box. According to the device, a driving mechanism and a lifting mechanism are independently arranged, the lifting mechanism only drives a mold to ascend and descend, the energy consumption of the lifting mechanism is effectively reduced, the production cost reduction of the device can be facilitated, in addition, the device production stability canbe improved, so that the device production efficiency can be conveniently improved, and the device production benefit increase can be facilitated.

Owner:CHANGXING MINGWANG RUBBER PROD

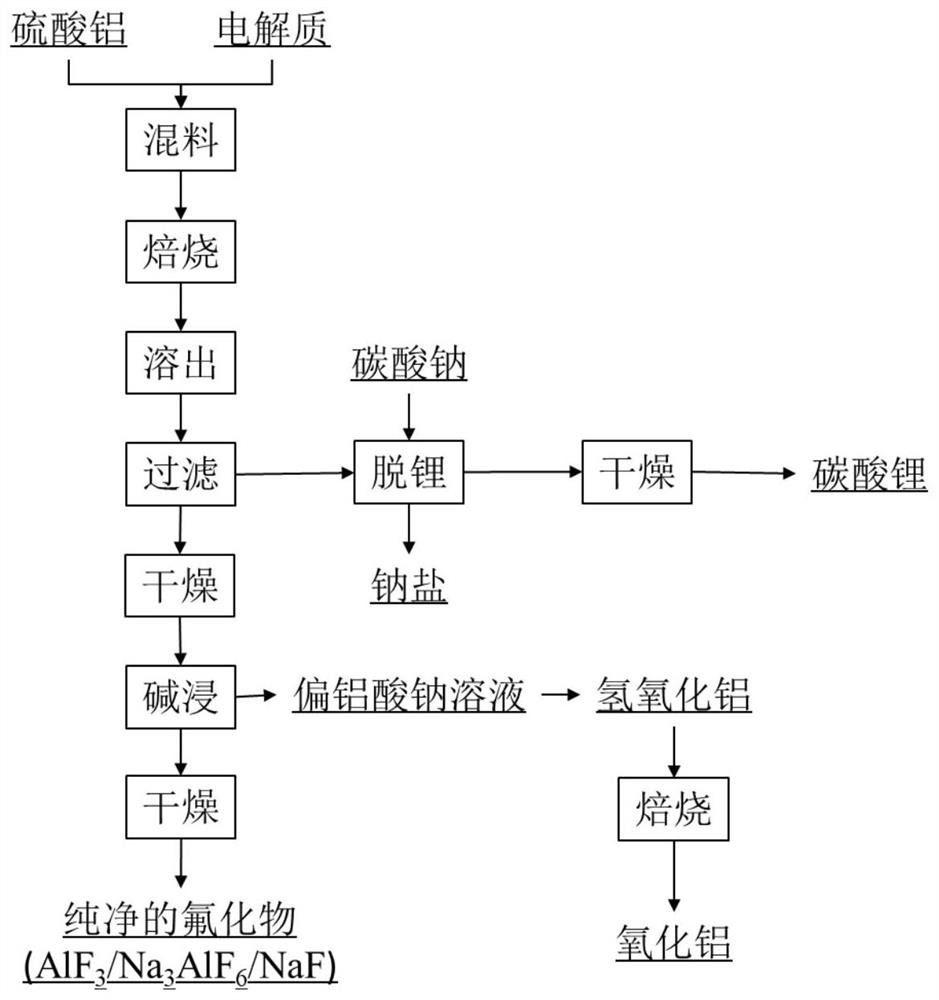

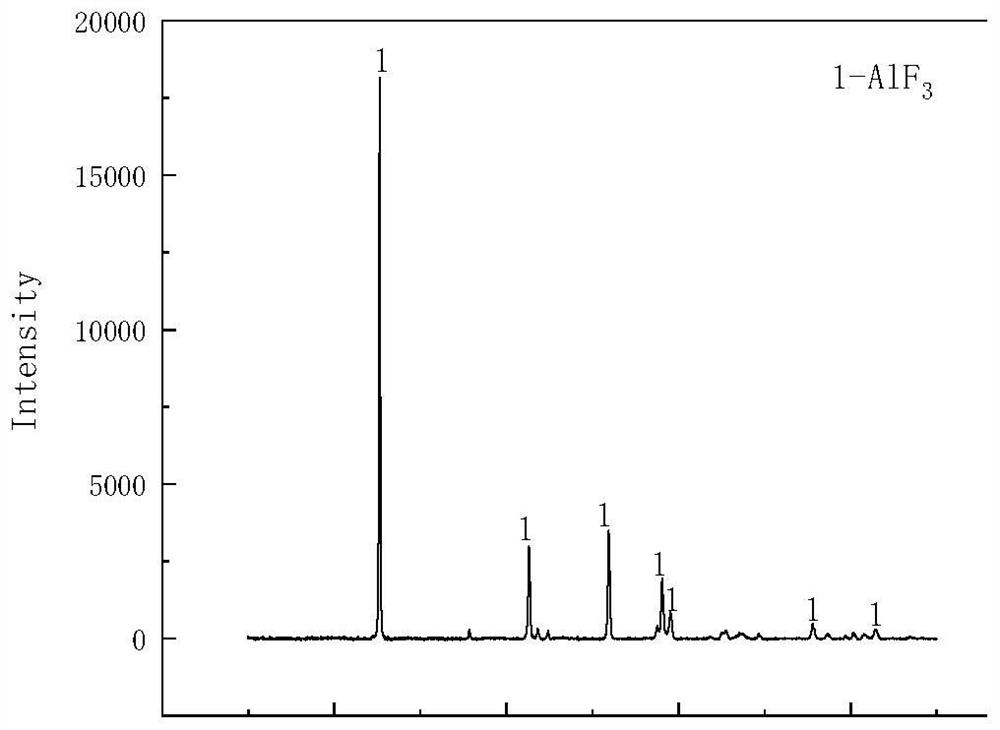

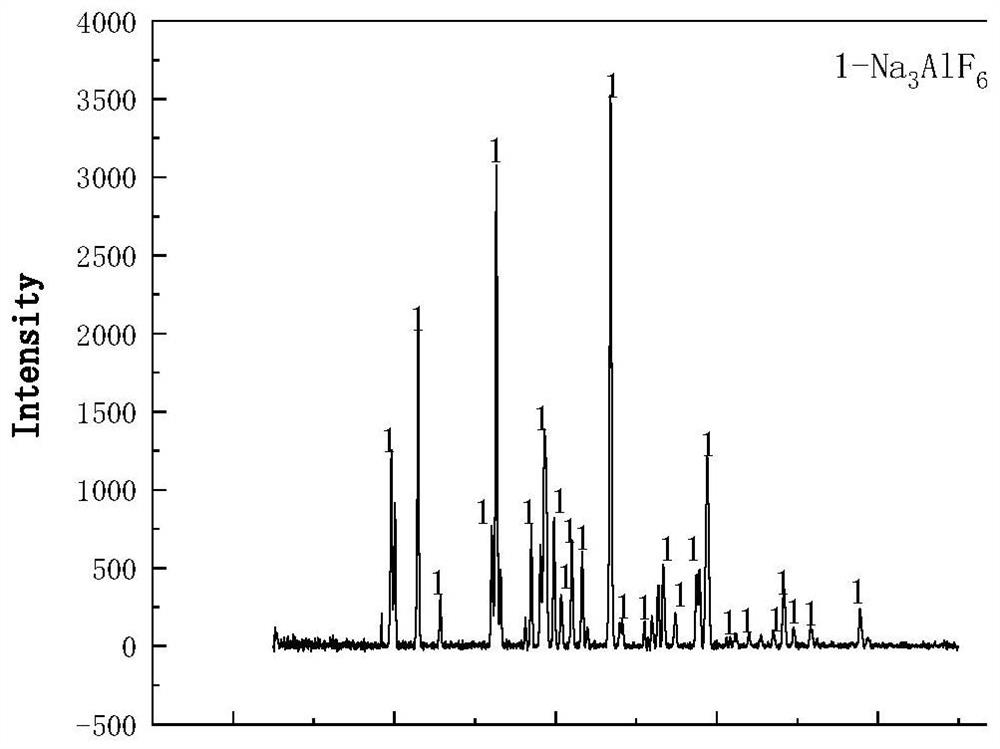

Method for recovering fluoride salt from complex aluminum electrolyte

ActiveCN114314625AConducive to stable productionThe process is simple and greenAlkali metal fluoridesAluminium fluoridesEngineeringWaste recycling

The invention belongs to the technical field of aluminum smelting solid waste recycling and reusing, and particularly relates to a method for recycling fluoride salt from complex aluminum electrolyte. According to the method for recovering the fluoride salt from the complex aluminum electrolyte, the complex aluminum electrolyte and the aluminum sulfate are used as raw materials, the processes of roasting, acid pickling dissolution, alkaline leaching, lithium removal, potassium removal, sodium removal and the like are sequentially carried out, a pure fluoride product (aluminum fluoride / sodium fluoride) is prepared, the whole process flow is simple and green, and the yield is high. According to the method, the fluorine element, the lithium element and the like in the complex aluminum electrolyte are recycled at the same time, HF is not generated, the resource utilization efficiency and economic benefits are improved, and stable production of electrolytic aluminum enterprises is promoted.

Owner:NORTHEASTERN UNIV

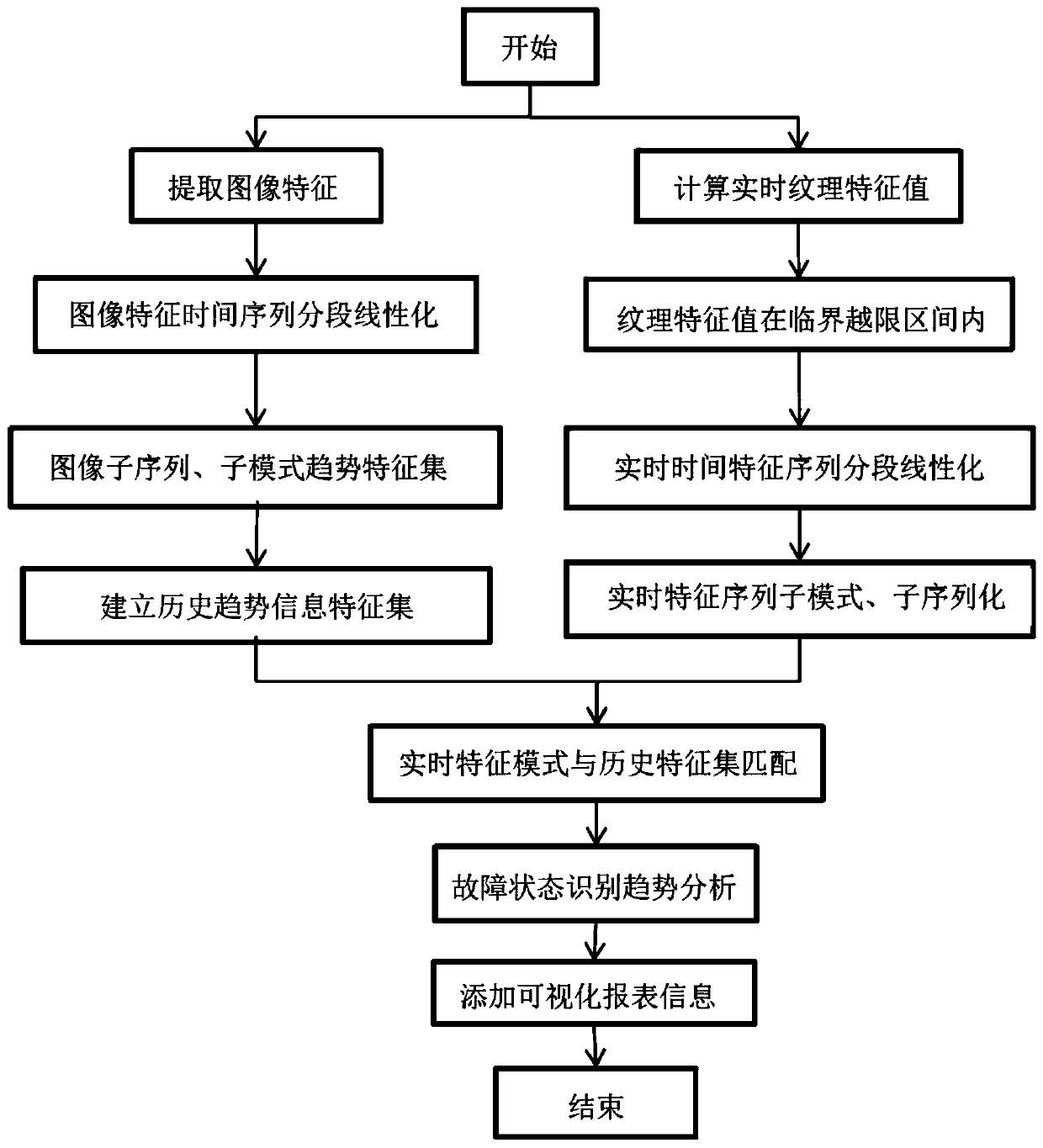

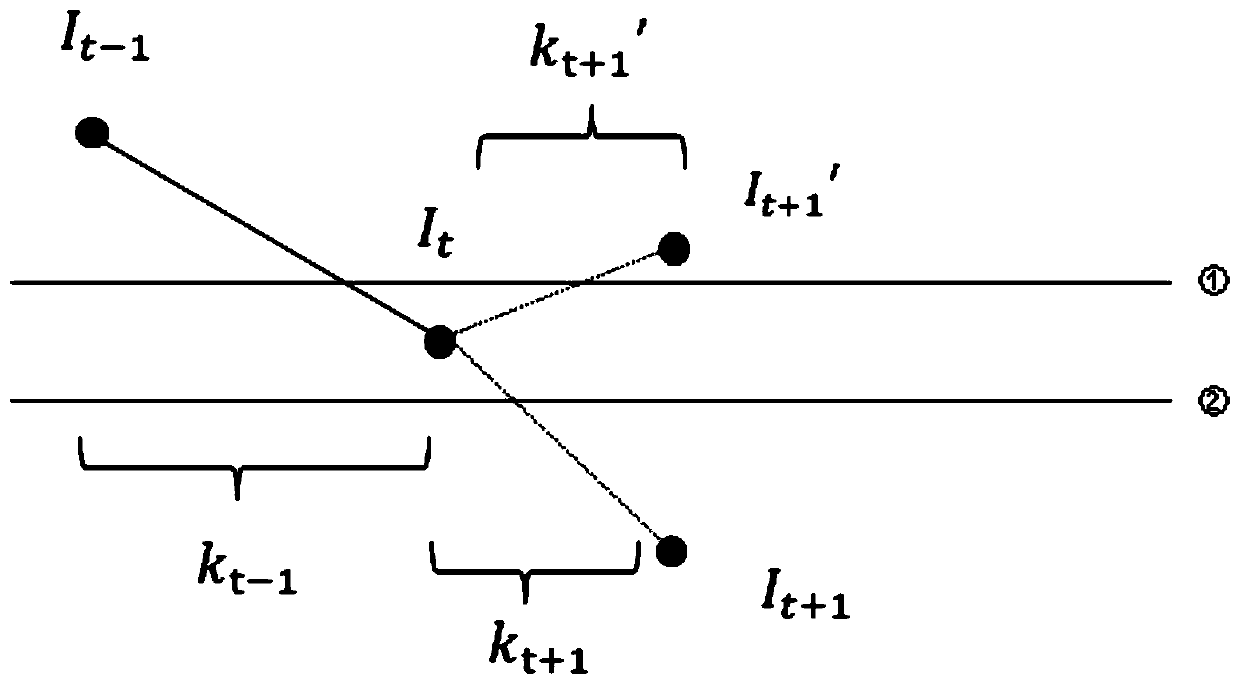

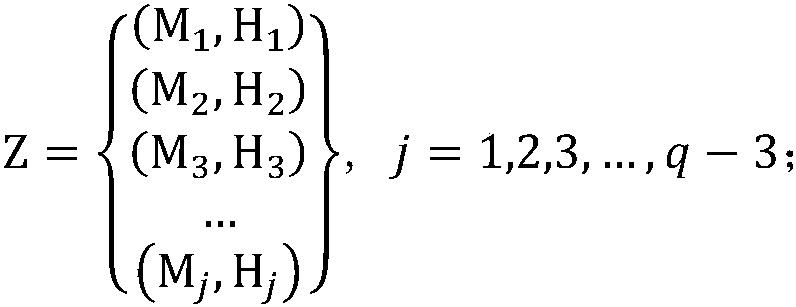

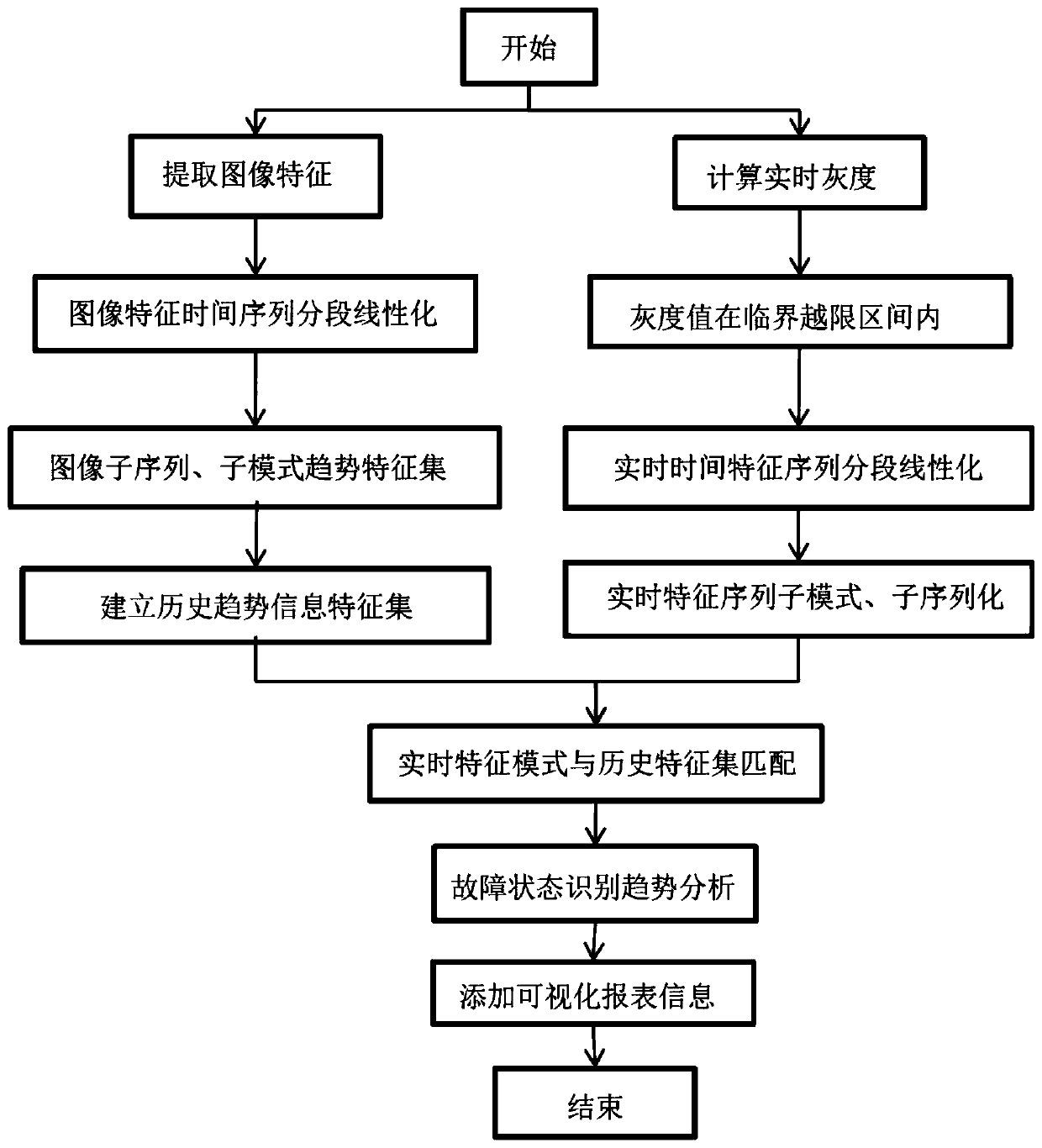

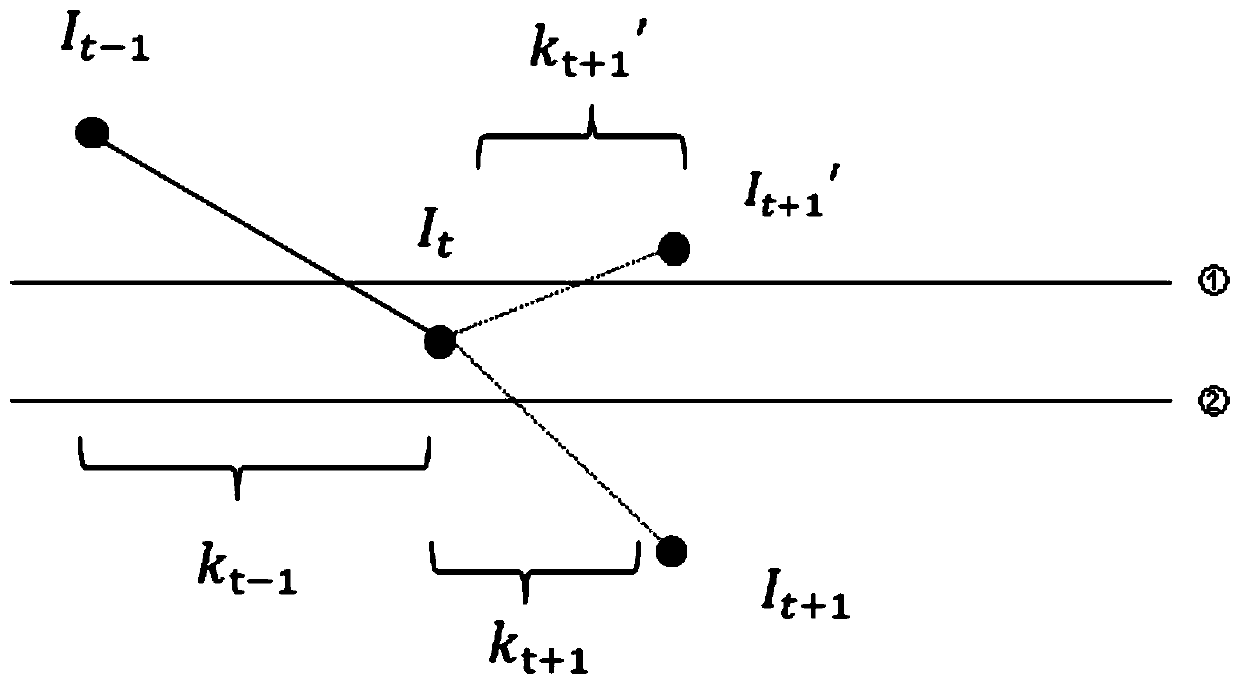

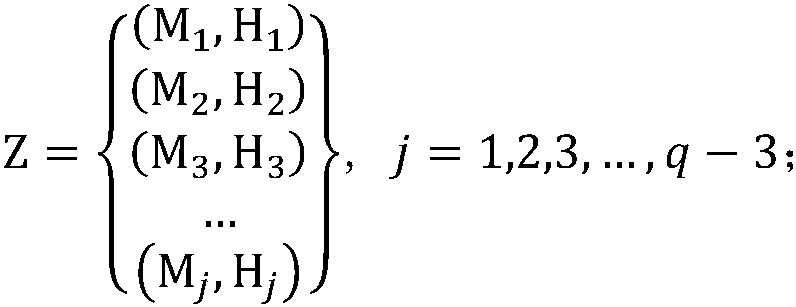

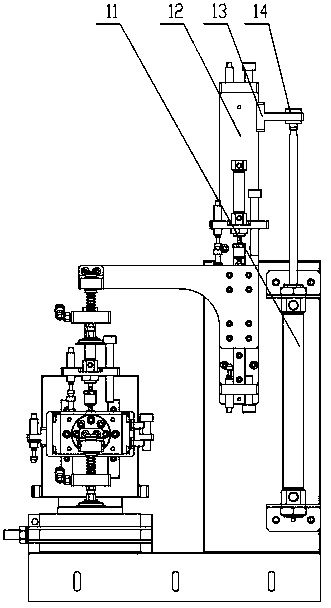

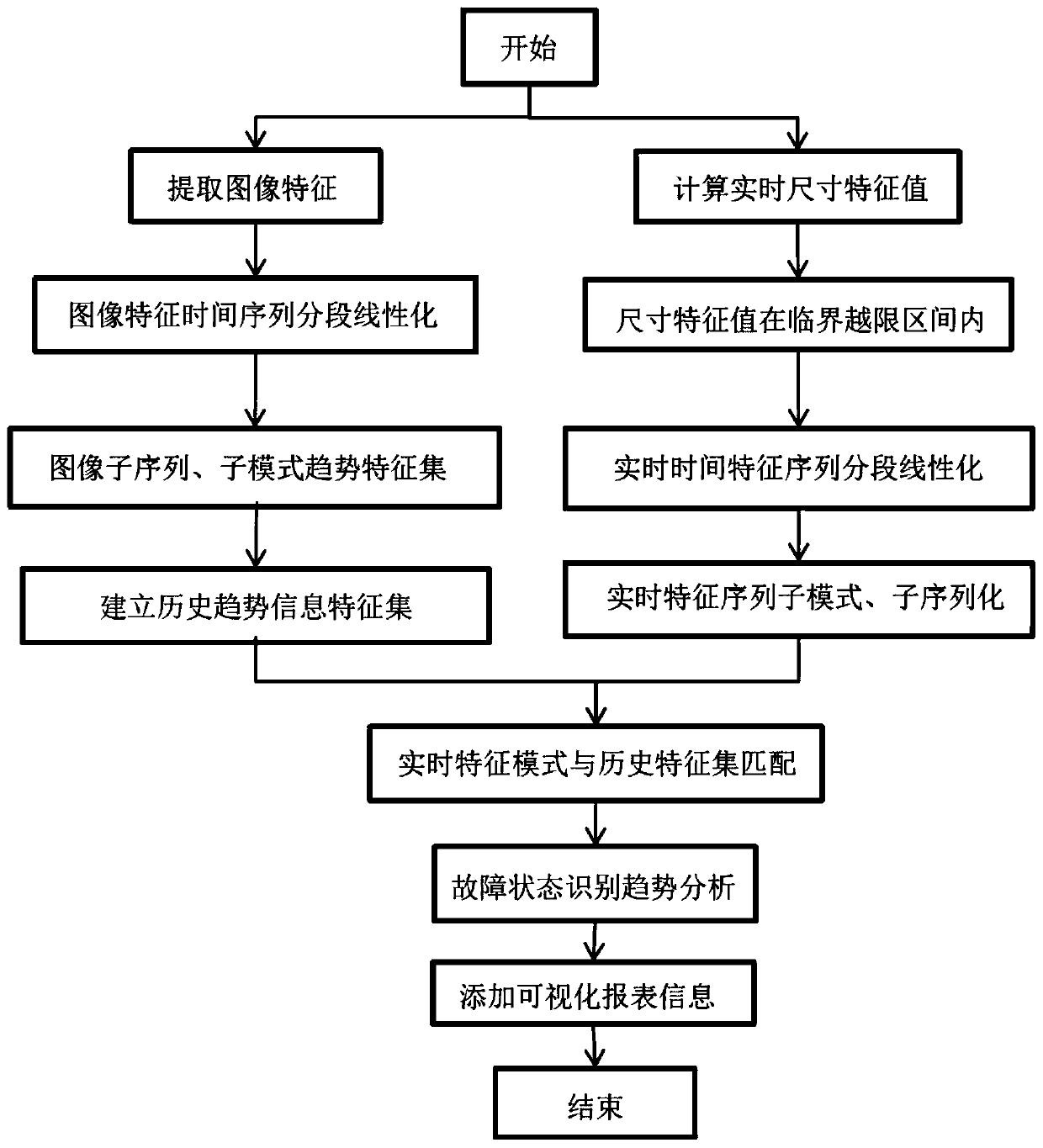

Flotation fuzzy fault diagnosis method based on texture time sequence trend feature matching

ActiveCN110175617AOvercome limitationsAdjust operations in timeCharacter and pattern recognitionState predictionFeature set

The invention discloses a flotation fuzzy fault diagnosis method based on texture time sequence trend feature matching. In the foam flotation field, the invention discloses a fuzzy fault diagnosis method for a flotation process, and the method is characterized in that based on the foam visual time sequence feature extraction, a sub-sequence and a sub-mode of a foam time sequence are defined, a historical feature trend information set is established by adopting historical data information, the similarity of real-time trend features and the historical trend feature set is measured, and the fuzzydiagnosis is performed on the fault occurrence probability by integrating the sequence trend information. According to the method, a concept of fuzzy fault diagnosis is provided, a flotation workingcondition state prediction representation model is established through the reliability sequence selection and the abnormal factor establishment, and a new solution is provided for the trend judgment and the numerical trend possibility. According to the method, the defect that the original foam characteristics statically describe the flotation process is overcome, the working condition abnormal symptoms are found in time, the fault possibility at the future moment is displayed in a numerical mode, the manual operation is facilitated, and the production is stably optimized.

Owner:CENT SOUTH UNIV

Culture medium for producing sodium hyaluronate and preparation method of culture medium

InactiveCN109161571AImprove stabilitySimplify complexityBacteriaMicroorganism based processesStreptococcus zooepidemicusArginine

The invention provides a culture medium for producing sodium hyaluronate and a preparation method of the culture medium. Each 100kg of culture medium comprises the following components: 28 to 35kg ofwhite granulated sugar, 8 to 12 kg of yeast extract powder, 0.8 to 1.1kg of MgSO4.7H2O, 1.2 to 1.4kg of NaH2PO4.2H2O, 0.5 to 1.0kg of K2SO4, 15 to 25kg of L-arginine and 15 to 30mL of a defoamer, andthe components are supplemented to be a total mass of 100kg with water. The culture medium provided by the invention simplifies the complexity of a formula, reduces impurities brought in, ensures thatthe yield of sodium hyaluronate can reach 7.5 to 8.5g / L when streptococcus zooepidemicus H23 is used for fermentation, and compared with the culture medium disclosed in the existing method, the culture medium provided by the invention is higher in fermentation yield in same conditions, facilitates industrial production, and improves the production efficiency.

Owner:SHANGHAI JINGFENG PHARMA

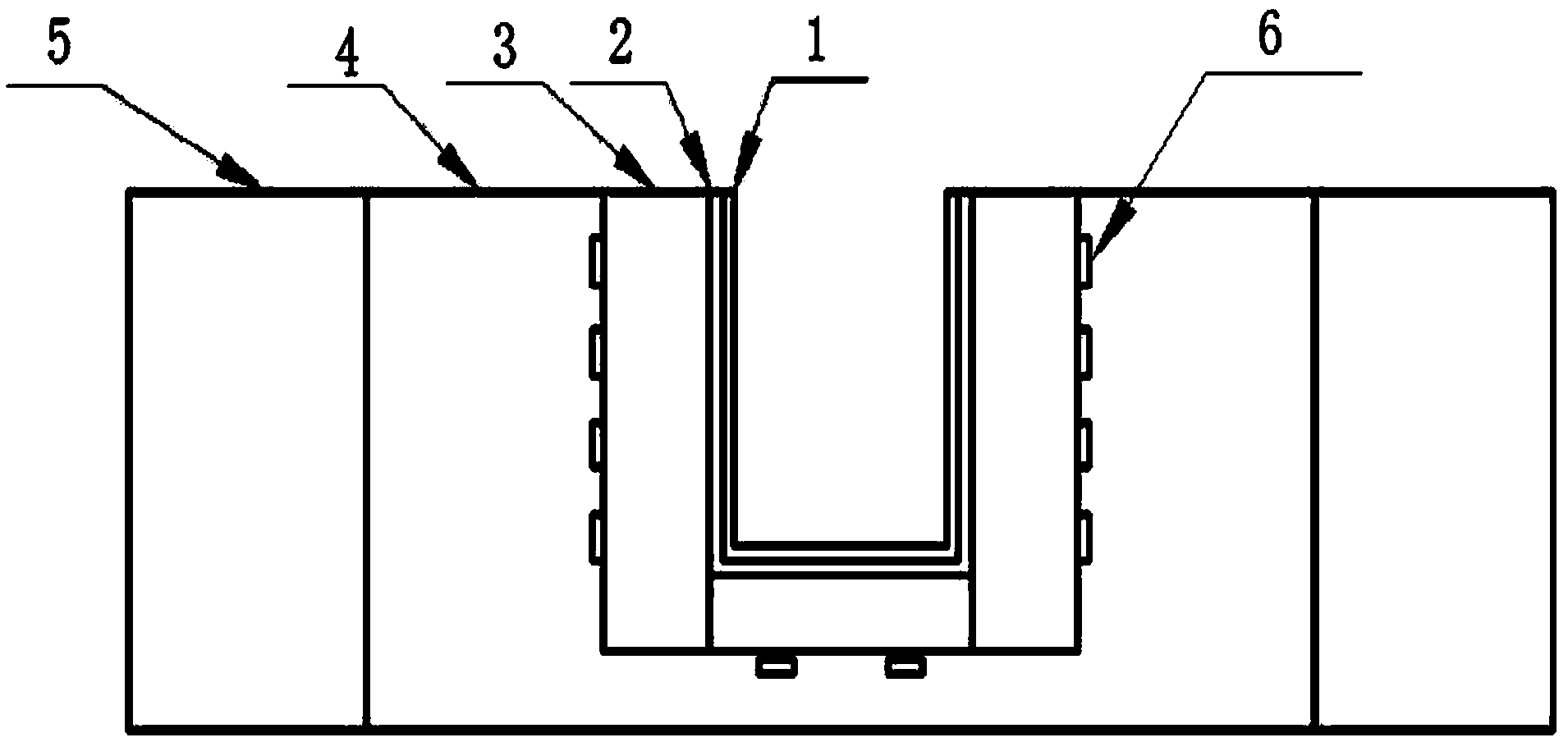

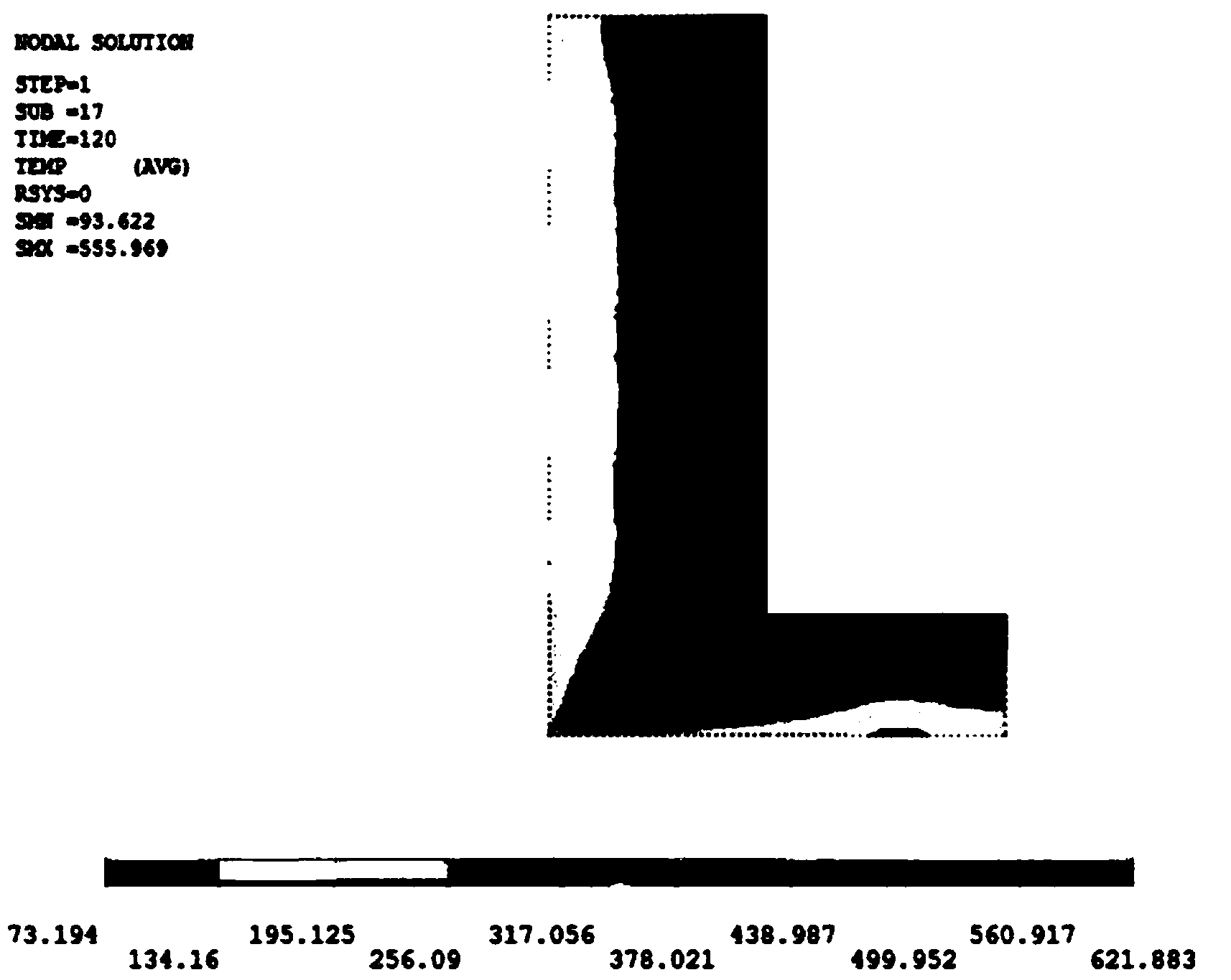

Ferrous metal liquid die forging mould and manufacturing method thereof

ActiveCN103706777AImprove working environmentAvoid Rapid Exception FailuresCoatingsThermal insulationCopper

The invention relates to a ferrous metal liquid die forging mould and a manufacturing method of the metal liquid die forging mould. A zirconium oxide or aluminum oxide coating is arranged on the inner surface of a mould cavity, diatomite thermal insulation coatings are arranged on the surface of the coating, the mould is sleeved with a copper sleeve, the copper sleeve is provided with a spiral cooling water channel which is arranged on the two sides and the bottom of the mould, and the copper sleeve is further sleeved with a supporting sleeve. The method comprises the following steps that (1), the mould is designed and manufactured according to a liquid die forge piece to be formed; (2), the zirconium oxide or aluminum oxide coating is sprayed on the inner surface of the mould cavity; (3), the mould is sleeved with the copper sleeve, the spiral cooling water channel is arranged on the copper sleeve, and the spiral cooling water channel is arranged on the two sides and the bottom of the mould; (4), the copper sleeve is sleeved with the supporting sleeve; (5), before each liquid die forge piece is forged, the diatomite thermal insulation coatings need to be sprayed on the surface of the coating of the mould. According to the ferrous metal liquid die forging mould and the manufacturing method of the metal liquid die forging mould, the temperature of the mould is decreased, and the service life of the ferrous metal liquid die forging mould is prolonged.

Owner:WUHAN UNIV OF TECH

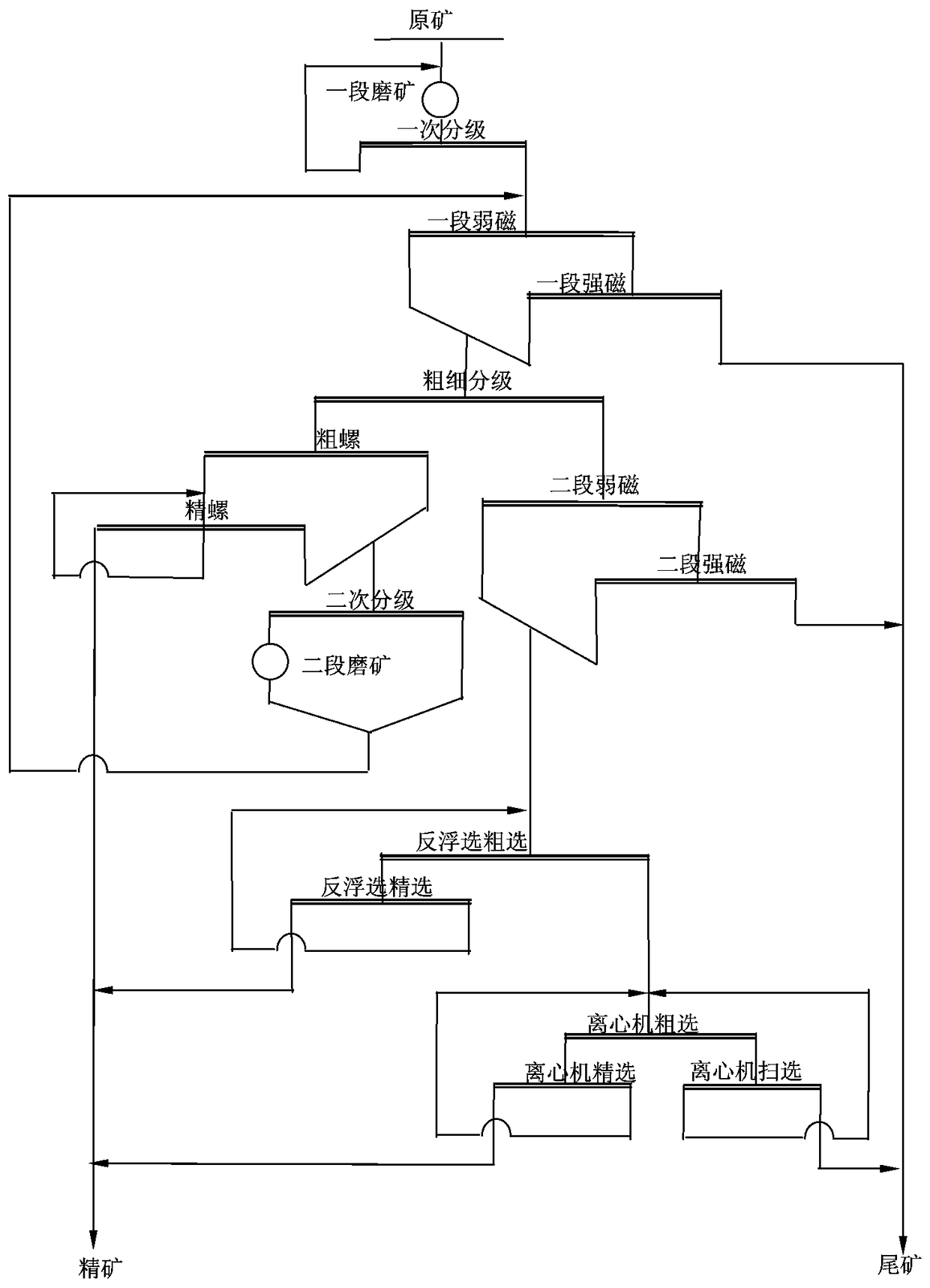

Magnetism-weight-flotation combined technology for separating hematite iron ore containing iron carbonate

InactiveCN108970803AConducive to stable productionReduce manufacturing costSolid separationGravity separationCoarse particle

The invention relates to a magnetism-weight-flotation combined technology for separating hematite iron ore containing iron carbonate. The magnetism-weight-flotation combined technology comprises the step that iron ore with the hematite distribution ratio being higher than 40% is fed in to be subjected to first-stage closed circuit grinding operation. The magnetism-weight-flotation combined technology is characterized in that the magnetism-weight-flotation combined technology further comprises the steps of first-stage weak magnet and strong magnet operation, thickness grading operation, gravityseparation operation, secondary staged ore grinding operation, second-stage weak magnet and strong magnet operation and reverse floatation operation; the first-stage weak magnet and strong magnet operation treats a primary grading overflow product and a middling ore re-grinding product; the thickness grading operation treats first-stage weak magnet and strong magnet mixed concentrate; the gravityseparation operation treats a coarse particle product after the thickness grading operation; the secondary staged ore grinding operation treats gravity separation operation tailings; the second-stageweak magnet and strong magnet operation treats a fine grain product after the thickness grading operation; the reverse floatation operation treats second-stage weak magnet and strong magnet mixed concentrate; and centrifuge separation operation treats middling ore after the reverse floatation operation. The magnetism-weight-flotation combined technology has the advantages that the middling circulation volume is reduced, a process flow is simplifies, and the manufacturing cost is reduced.

Owner:ANSTEEL GRP MINING CO LTD

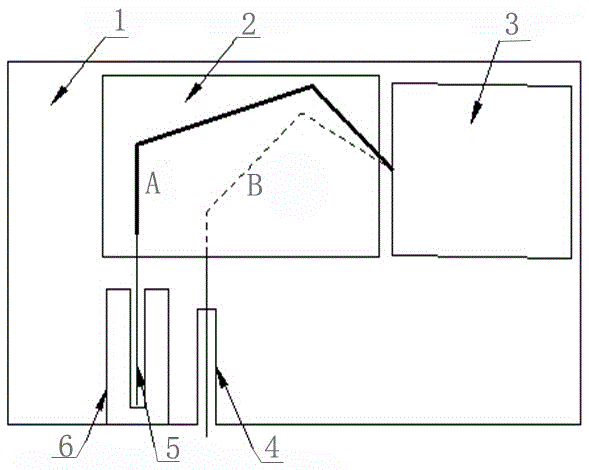

Device for monitoring PAG water base quenching medium cooling performance on line

InactiveCN106566919AOptimizing management methodsGuarantee normal continuous production and useHeat treatment process controlQuenching agentsWater basedControl manner

The invention provides a device for monitoring PAG water base quenching medium cooling performance on line. The device comprises an automatic cooling speed monitoring instrument, the automatic cooling speed monitoring instrument is connected with a control PC, the control PC is connected with a transmission device in a control manner, and a detecting sensor is then arranged on the transmission device; the detecting sensor is placed in a heating furnace for preheating; and a detecting opening of the detecting sensor is further arranged on the side edge of the heating furnace and corresponds to the portion above a PAG water base quenching medium. According to the device, the transmission device is used for placing the detecting sensor into the heating furnace for preheating, then the detecting sensor is placed into the PAG water base quenching medium to conduct on-line monitoring, the simulation effect is achieved by the device, and the truth of monitoring results is conveniently guaranteed.

Owner:SHIYAN SHUANGQI TECH CO LTD

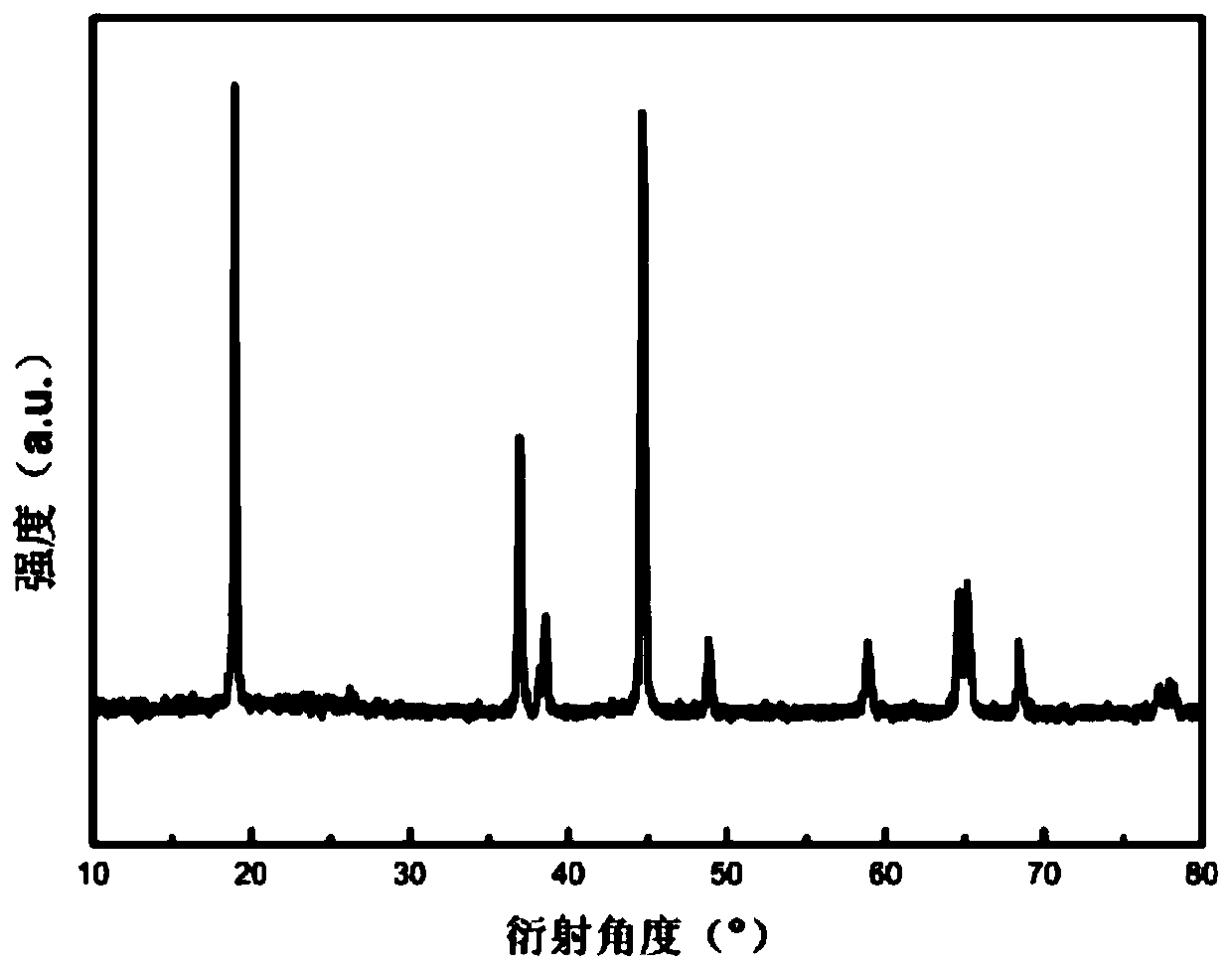

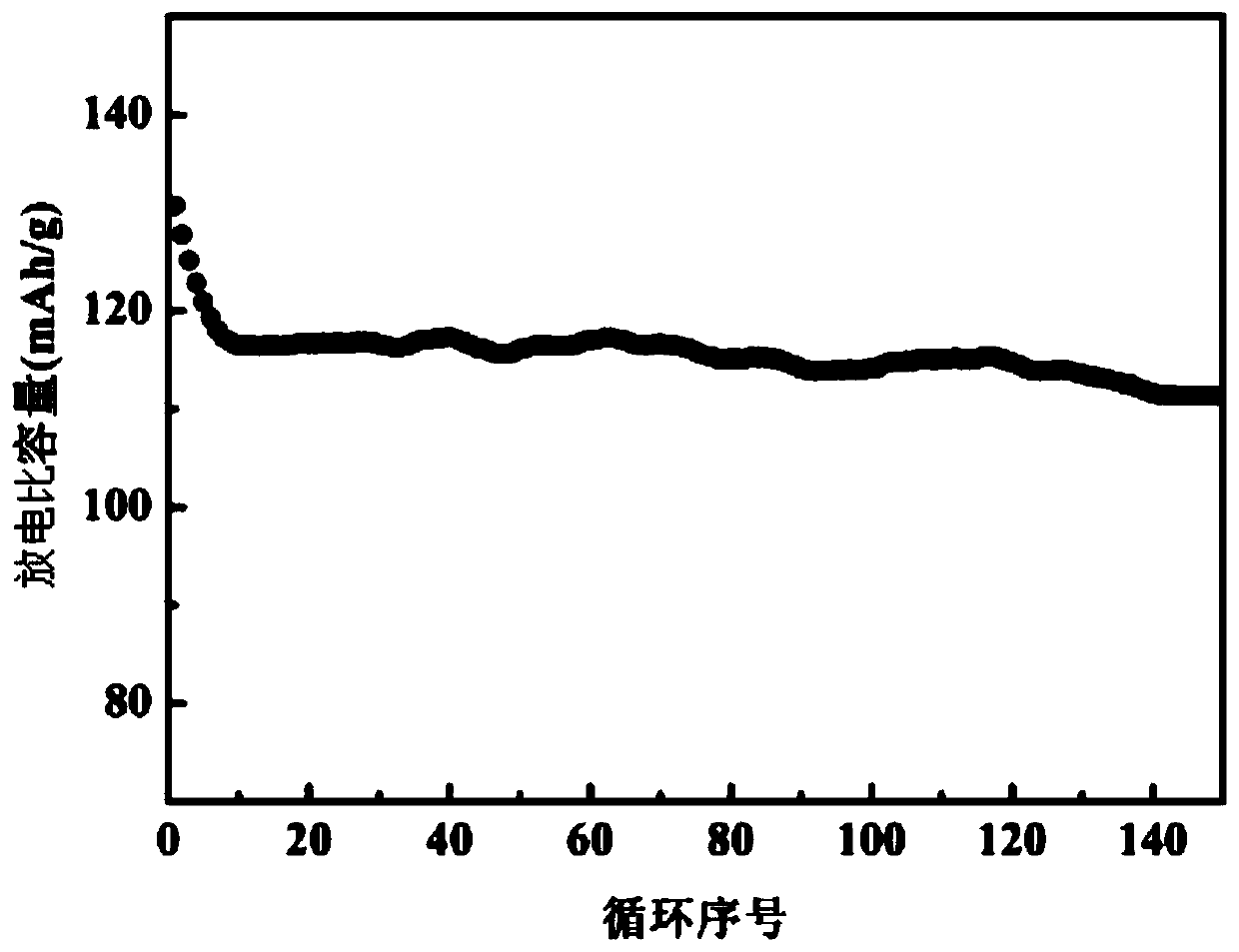

Ternary cathode material of lithium ion battery and preparation method thereof

InactiveCN111342041AImprove uniformityImproves stability and tightnessCell electrodesSecondary cellsCobalt oxideLithium electrode

The invention discloses a ternary positive electrode material of a lithium ion battery and a preparation method of the ternary positive electrode material. According to the ternary cathode material ofthe lithium ion battery, high-nickel lithium nickel cobalt oxide is used as a modified matrix, and precursor powder is pressed by external mechanical pressure for modification. The preparation methodcomprises the following steps: stirring and mixing indissolvable inorganic salts of nickel, cobalt and manganese elements and lithium salt in deionized water, and preparing precursor powder through ball milling and spray drying; pressing the precursor powder into a cake-shaped solid under the action of external mechanical pressure; grinding and sieving the cake-shaped solid, and performing heating and calcining to obtain powder, namely the ternary material of the lithium ion battery. According to the invention, the precursor of the high-nickel lithium nickel cobalt manganate material is pressed by external mechanical pressure; compared with the prior art, the method has the advantages of simple operation, low cost, and facilitation of realization of commercial production of the high-nickel lithium cobalt manganate ternary material by enterprises, and the tap density of the high-nickel lithium cobalt manganate ternary material is improved, and uniform active particles are obtained, sothe high-nickel lithium cobalt manganate ternary material has high specific capacity and good cycle performances under a large multiplying power.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

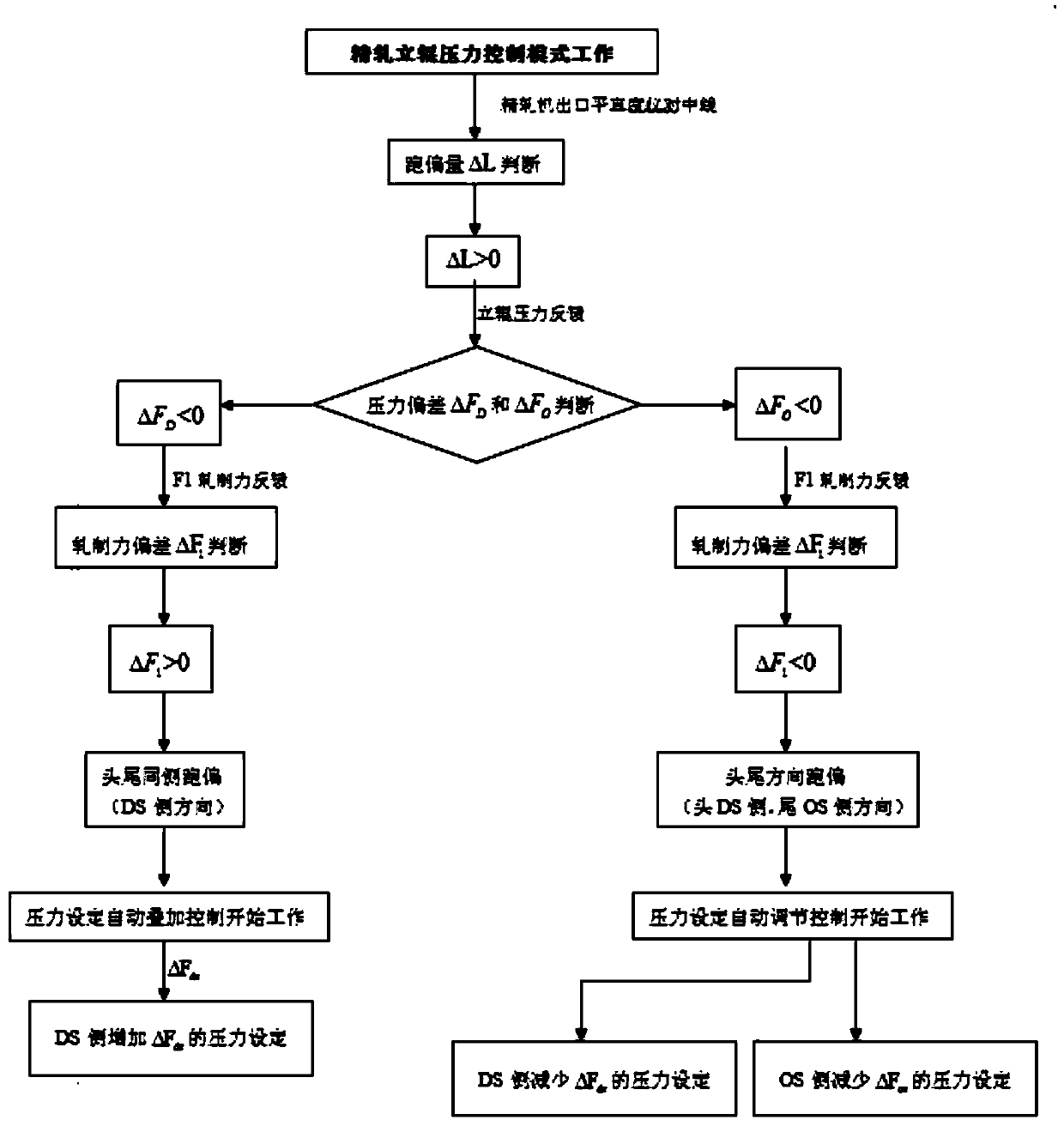

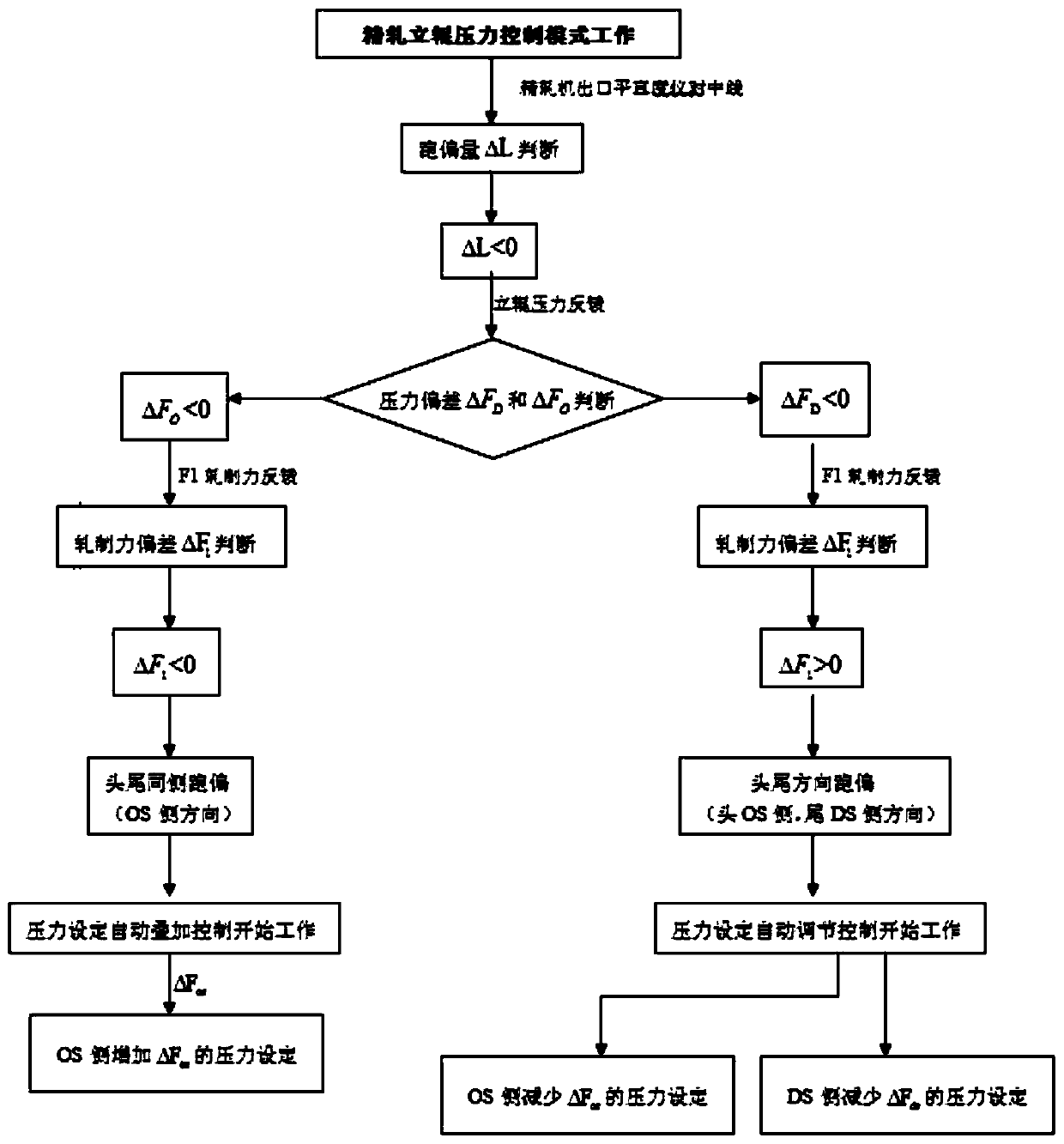

Control method of strip steel deviation correction based on finish rolling vertical rolls

ActiveCN110711771AImprove deviationReduce driftRoll mill control devicesMeasuring devicesStrip steelRolling mill

The invention discloses a control method of strip steel deviation correction based on finish rolling vertical rolls. The control method of the strip steel deviation correction based on the finish rolling vertical rolls specifically includes the following steps: S1, judging deviation types of strip steel based on deviation, detected on an exit of a finishing mill F7, of a strip steel rolling line and rolling force of an F1 rolling mill, wherein the deviation types include a head-tail ipsilateral deviation type and a head-tail reverse deviation type; and S2, regulating and controlling pressure of the vertical rolls on the DS (drive side) and / or the OS (operation side) according to the deviation types of the strip steel, and mitigating the deviation degree of the strip steel through the pressure of the vertical rolls on the DS and / or the OS. The control method of the strip steel deviation correction based on the finish rolling vertical rolls detects the deviation types of the strip steel,controls pressure output of the vertical rolls on the two sides based on the deviation types so as to improve the deviation degree of the strip steel, reduces occurrence frequency of the deviation situation of the center line in the finish mill in rolling of the strip steel, improves product quality, facilitates stable production of the hot rolling, and brings good benefit.

Owner:MAANSHAN IRON & STEEL CO LTD

Base material for artificial leather and process for producing the same

ActiveUS9752260B2Reducing friction and interactionIncrease volumeSynthetic resin layered productsFilament/thread formingFiber bundleVolumetric Mass Density

A substrate for artificial leather comprising a nonwoven fabric of bundles of microfine filaments. The substrate for artificial leather simultaneously satisfies the following requirements 1 to 4: (1) the bundle of microfine filaments comprises 8 to 70 microfine filaments having a cross-sectional shape of nearly circle; (2) the bundle of microfine filaments has a cross-sectional area of 170 to 700 μm2 and a flatness of 4.0 or less; (3) on a cross section parallel to a thickness direction of the nonwoven fabric body, cross sections of the microfine fiber bundles exist in a density of 1500 to 3000 / mm2; and (4) on a cross section parallel to a thickness direction of the nonwoven fabric body, gaps between the microfine fiber bundles have a size of 70 μm or less. By satisfying the requirements, the substrate for artificial leather combines high level of sensuous qualities and high level of physical properties which have been considered to be mutually exclusive.

Owner:KURARAY CO LTD

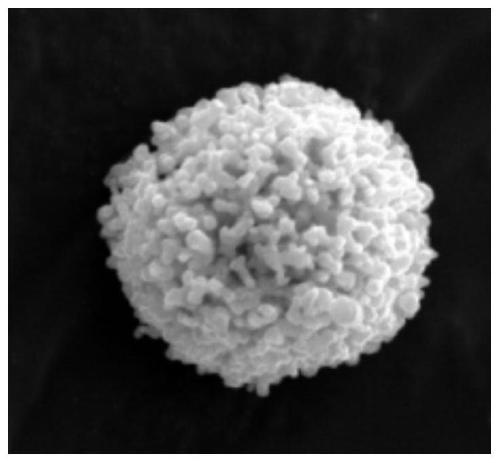

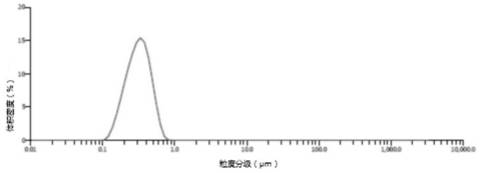

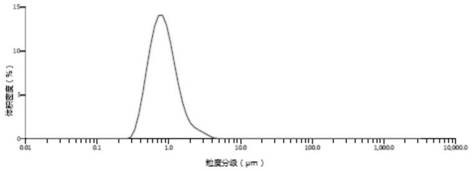

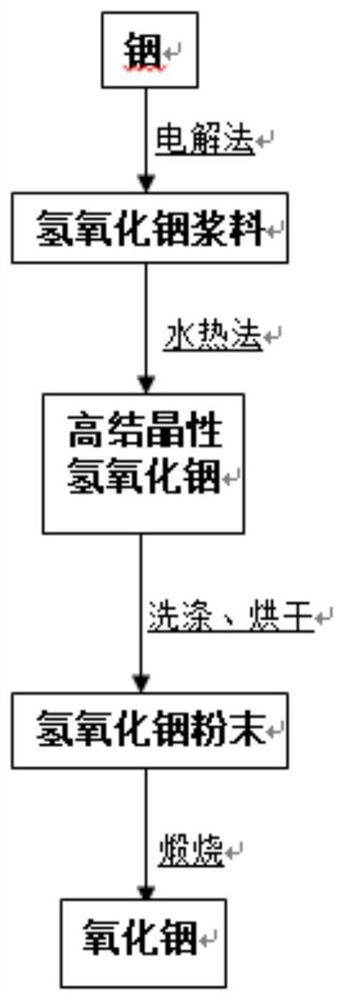

High-dispersity indium oxide and preparation method thereof

InactiveCN112645379AGood dispersionHigh crystallinityElectrolysis componentsGallium/indium/thallium compoundsElectrolytic agentCrystallinity

The invention provides high-dispersity indium oxide and a preparation method thereof. The preparation method comprises the following steps: a) taking metal indium as an anode, an inert electrode as a cathode and an ammonium nitrate aqueous solution as an electrolyte, and obtaining indium hydroxide slurry through an electrolytic method; b) adding an indium nitrate solution into the indium hydroxide slurry obtained in the step a) to enable the mass ratio of the added indium ions to indium hydroxide to be 0.01%-1%, adjusting the pH value to be 4-8, then carrying out hydrothermal reaction, and washing and drying a product to obtain indium hydroxide powder with high crystallinity and high dispersity; and c) calcining the high-crystallinity and high-dispersity indium hydroxide powder obtained in the step b) to obtain the high-dispersity indium oxide. According to the preparation method, indium hydroxide and indium oxide which are uniform in size distribution, high in dispersity and complete in crystal structure are successfully prepared in an electrolytic hydrothermal method combined mode, and the problem that indium oxide prepared from fine indium hydroxide powder synthesized through a common electrolytic method is prone to agglomeration in the calcining process is solved.

Owner:FIRST RARE MATERIALS CO LTD

Preparing method of high-strength copper-based composite toughened by boron carbide and silicon carbide crystal whiskers

The invention belongs to the field of nonferrous metal composites, in particular to a method for toughening a high-strength copper-based composite by nanometer boron carbide and silicon carbide crystal whiskers. An in-situ generated high-strength copper-based composite powder toughened by boron carbide and silicon carbide crystal whiskers consists of high-strength copper-based composite base material powder and nanometer boron carbide and silicon carbide crystal whisker powder. The high-strength copper-based composite base powder is uniformly mixed with the nanometer boron carbide and silicon carbide crystal whisker powder by a mechanical mixing process, a vacuum-sintered hot-pressed ingot is enabled to deform through extrusion, and the in-situ generated high-strength copper-based composite toughened by the nanometer boron carbide and silicon carbide crystal whiskers is obtained. As the in-situ generated copper-based composite toughened by the nanometer boron carbide and silicon carbide crystal whiskers has high tenacity, and at the same time, the wear resistance and the strength are greatly improved, the copper-based composite is particularly suitable for high-speed railway high-strength cables, high-end equipment manufacturing industry and the like and is particularly suitable for being used as a material for cutters, dies, aviation, aerospace and the like.

Owner:SHANDONG JIANZHU UNIV

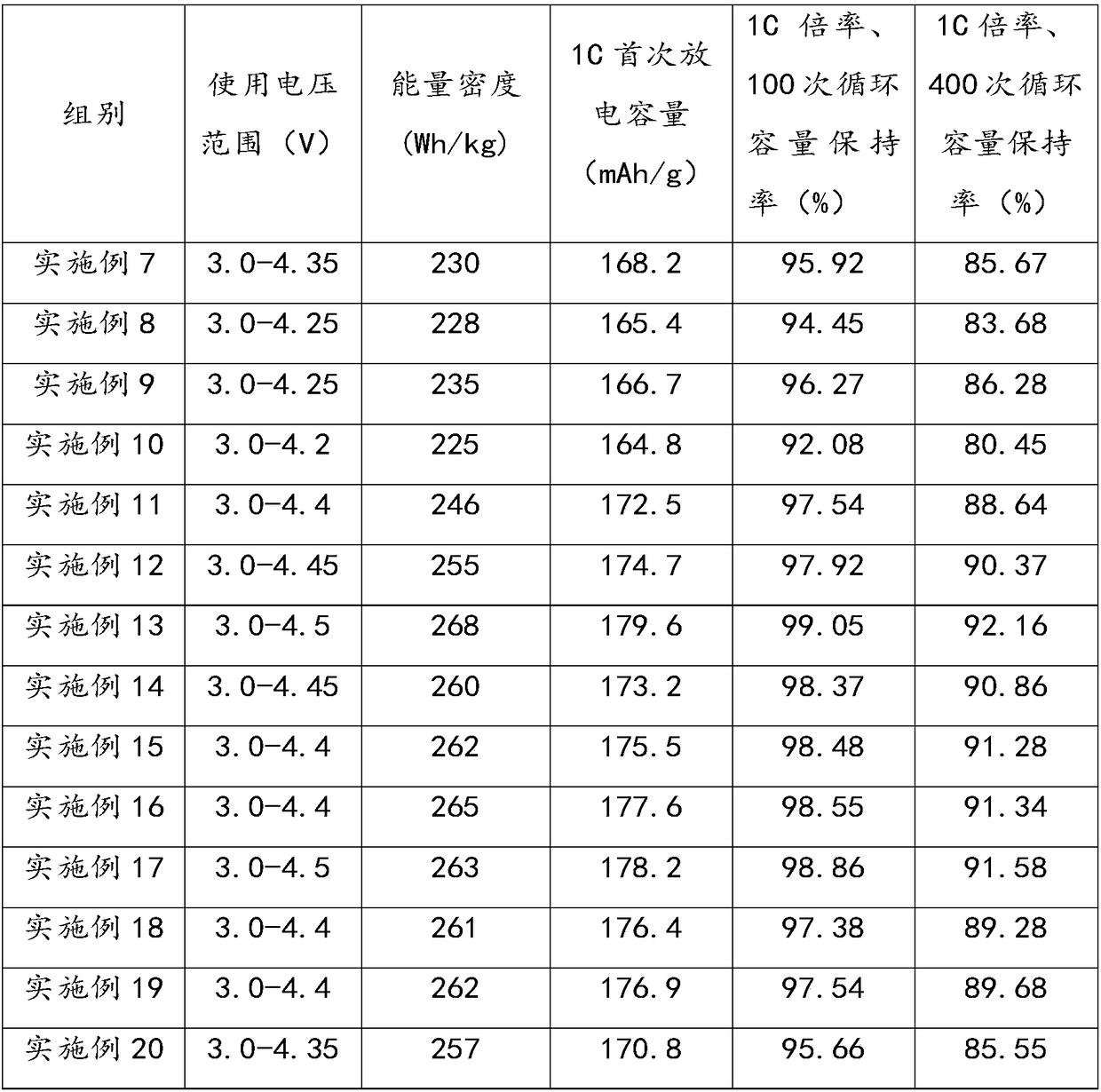

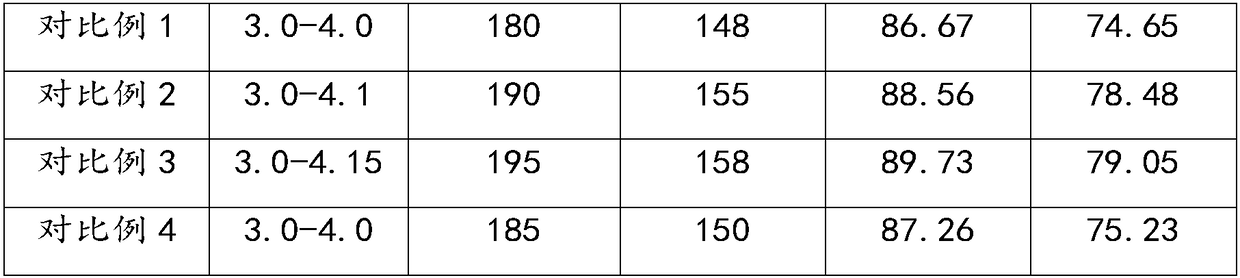

Positive material of high-voltage lithium ion battery, lithium ion battery and preparation method thereof

InactiveCN108155362AImprove thermal stabilityImprove structural stabilityCell electrodesFinal product manufactureHeat stabilityPhysical chemistry

The invention belongs to the technical field of lithium ion batteries and relates to a positive material of a high-voltage lithium ion battery, the lithium ion battery and a preparation method thereof. The positive material of the high-voltage lithium ion battery is prepared from the following raw materials in percent by weight: 92%-98% of positive active substance with a single-crystal structure,1%-4% of conductive agent and 1%-4% of binding agent, wherein the structural formula of the positive active substance with the single-crystal structure is LiNixCoyMn1-x-yO2; in the formula, x is morethan 0.4 and less than 0.9, y is more than 0 and less than 0.4, and 1-x-y is more than 0 and less than 1. The positive material has good structural stability and higher heat stability in the processof high-voltage circulation, so that the defects of easy structure change and the like of the existing positive material when in use under a high voltage due to poor heat stability are relieved.

Owner:BEIJING NAT BATTERY TECH

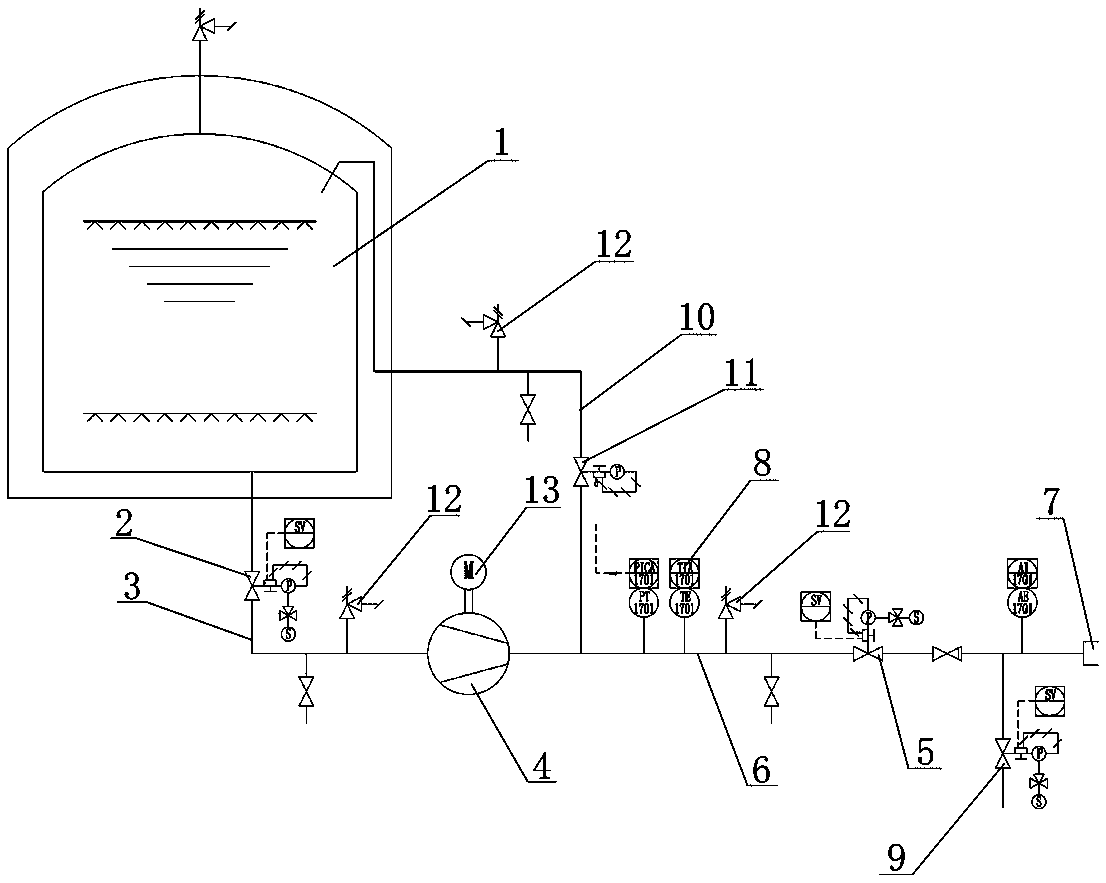

Automatic filling system and automatic filling method for low-temperature liquid storage tank

PendingCN108468946AImprove filling efficiencyConducive to stable productionPipeline systemsInlet valveSurveillance camera

The invention relates to an automatic filling system and automatic filling method for a low-temperature liquid storage tank. The low-temperature liquid storage tank is connected with a vehicle liquidfilling pump through an automatic filling inlet valve and a first connecting pipeline. The vehicle liquid filling pump is connected to a filling port through an automatic filling outlet valve and a second connecting pipe. The automatic filling inlet valve, the vehicle liquid filling pump and the automatic filling outlet valve are correspondingly connected with and controlled by a center console arranged outside, and the center console is further connected with a plurality of on-site video monitors and all instrument measuring points. The automatic filling system is controlled by the centre console through being equipped with monitoring cameras, voice intercom, lighting and other facilities on site, and the automatic filling system has the characteristics of simple structure, safety, reliability, rationality and high efficiency, reduction of labor cost, substantial improvement of labor productivity and replacement of manual operation in low-temperature dangerous environment.

Owner:盈德气体工程(浙江)有限公司

Method for extracting and separating high-purity yttrium from naphthenic acids in high stability

ActiveCN105200249AGuaranteed normal phase separationSimple processProcess efficiency improvementPhysical chemistryAnalytical chemistry

The invention relates to a method for extracting and separating high-purity yttrium from naphthenic acids in high stability, which still can guarantee a suitable phase ratio in a mixing chamber to guarantee the mixing chamber to be a sticky state when oil and water phases are extremely large or have severe fluctuation during the process that the high-purity yttrium is extracted and separated form the naphthenic acids, thereby enabling mixing phases to be rapidly clarified and separated in a clarifying chamber. The method for exacting and separating high-purity yttrium from naphthenic acids in high stability is simple in process, can rapidly and steadily adjust the phase radio of the naphthenic acids for extracting and separating the high-purity yttrium in the mixing chamber by adopting simple operation steps, rapidly builds a mixing chamber sticky system again, guarantees the clarifying chamber to normally separate phases, is simple in operation and excellent in stability, reduces technical requirements to operators, and is beneficial for stable production of enterprises.

Owner:CHALCO GUANGXI RARE EARTH DEV CO LTD

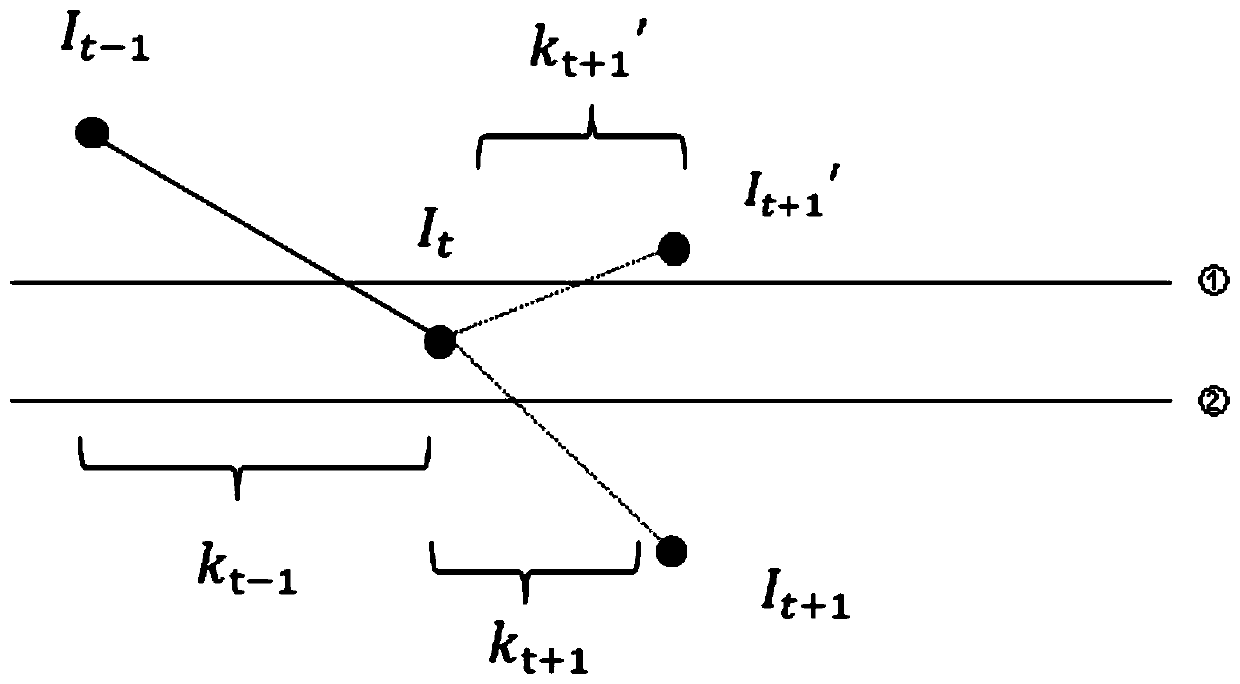

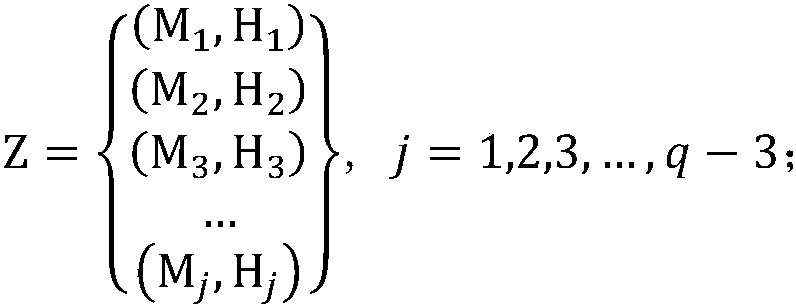

Fuzzy fault diagnosis method for zinc flotation process based on time series characteristics

ActiveCN110109446AOvercome limitationsAdjust operations in timeProgramme controlElectric testing/monitoringData informationTime trends

The invention relates to a fuzzy fault diagnosis method for a zinc flotation process based on time series characteristics, and belongs to the field of froth flotation. The invention discloses a fuzzyfault diagnosis mode in a flotation process, which is based on foam visual time sequence feature extraction, defines subsequences and submodes of a foam time sequence, establishes a historical featuretrend information set by adopting historical data information, measures the similarity of real-time trend features and the historical trend information set, and performs fuzzy diagnosis on the faultoccurrence probability by integrating sequence trend information. The invention provides a concept of fuzzy fault diagnosis, establishes a flotation condition state forecast representation model through reliability sequence selection and abnormal factor establishment, and provides a new solution for judgment of trend and possibility of numerical trend. The defect that the flotation process is statically described by the original foam characteristics is overcome, abnormal signs of the working conditions are found in time, the probability of faults at the future moment is displayed in a numerical mode, and the method is beneficial to workers to operate in time and stably optimize production.

Owner:CENT SOUTH UNIV

Turnover mechanism applied to automatic detection

Owner:DONGGUAN UNIV OF TECH +1

A titanium oxide-titanium carbide whisker toughened magnesium alloy biomedical material

ActiveCN106119742BImprove toughnessImprove corrosion resistanceProsthesisTitanium carbideTitanium oxide

The invention belongs to the field of biomedical materials and particularly relates to a titanium oxide-titanium carbide whisker toughened magnesium alloy biomedical material. The titanium oxide-titanium carbide whisker toughened magnesium alloy biomedical material is composed of magnesium alloy substrate material powder and titanium oxide-titanium carbide whisker powder; the magnesium alloy substrate material powder and the titanium oxide-titanium carbide whisker powder are uniformly mixed through a mechanical mixing method; the mixed powder is subjected to cold pressing, vacuum heating degassing and vacuum sintering; and a heat pressing ingot is subjected to equal channel deformation, so that the titanium oxide-titanium carbide whisker toughened magnesium alloy biomedical material is obtained. The toughness, the abrasion resistance and the strength of in-situ generated titanium oxide-titanium carbide whisker toughened magnesium alloy are remarkably improved, and the in-situ generated titanium oxide-titanium carbide whisker toughened magnesium alloy is especially suitable for the biomedical material and also can be applied to parts such as high-end sports car magnesium alloy hubs requiring for high strength and high abrasion resistance.

Owner:SHANDONG JIANZHU UNIV

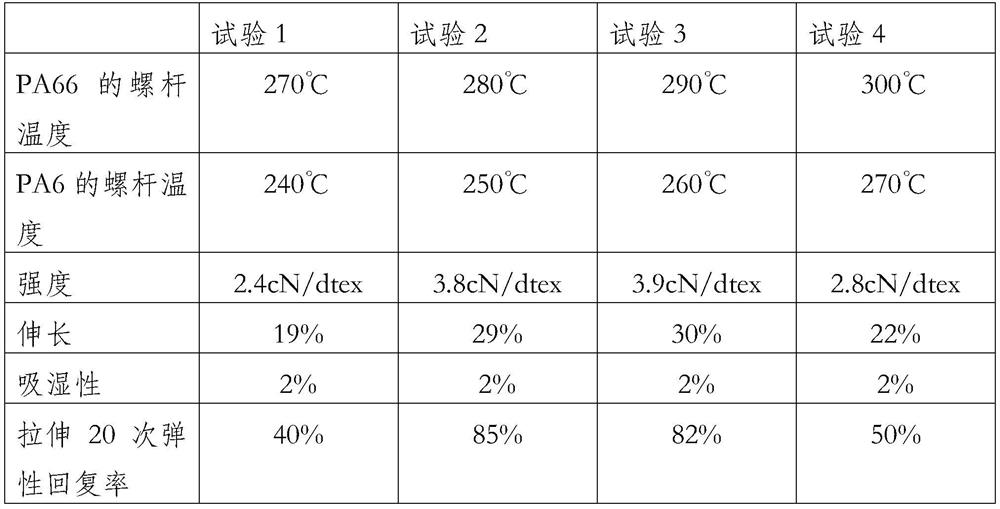

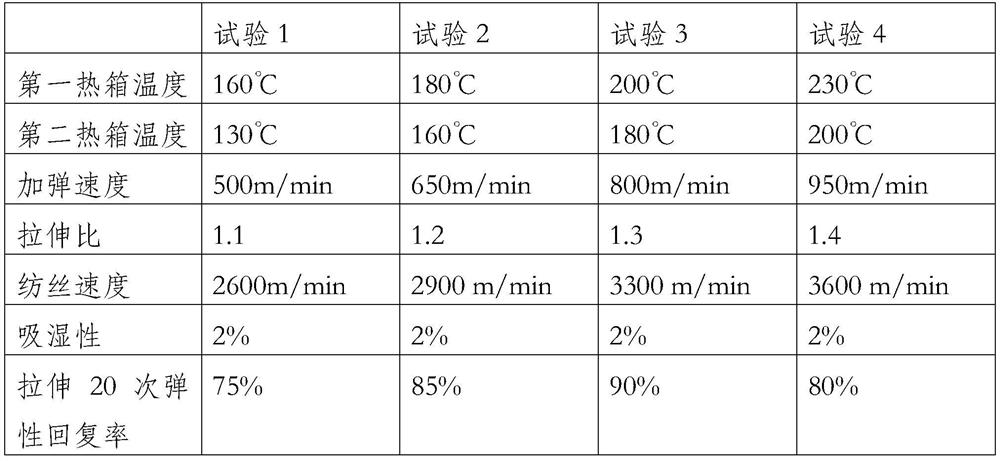

Preparation method of parallel 8-shaped multi-dimensional crimped PA6/PA66 double-component fibers and product thereof

ActiveCN112301458AGuaranteed shape stabilityComfortable wearing experienceArtificial filament heat treatmentMelt spinning methodsYarnFiber

The invention discloses a preparation method of parallel 8-shaped multi-dimensional crimped PA6 / PA66 double-component fibers and a product thereof. The preparation method comprises the following steps: PA6 slices are selected as one raw material, and PA66 is selected as the other raw material, wherein the mass ratio of the PA6 to the PA66 is 1: 2-2: 1; two-component spinning is carried out throughtwo screws, the screw temperature of the PA66 is set to be 270-300 DEG C, the screw temperature of the PA6 is set to be 240-270 DEG C, and POY pre-drawn yarn is prepared; and preparation of the PA6 / PA66 two-component composite DTY fiber is achieved: the prepared PA6 / PA66 two-component composite pre-drafted POY fiber is elasticized through an elasticizer to prepare the PA6 / PA66 two-component composite DTY fiber. The composite fiber is of a parallel 8-shaped multi-dimensional crimped structure, the hand feeling of the prepared yarn is cotton feeling and wool feeling, and the spun fabric has thestyle and comfort of a natural fabric and also has the characteristics of aging resistance and mildew resistance of chemical fibers.

Owner:ZHEJIANG YINYU NEW MATERIAL CO LTD

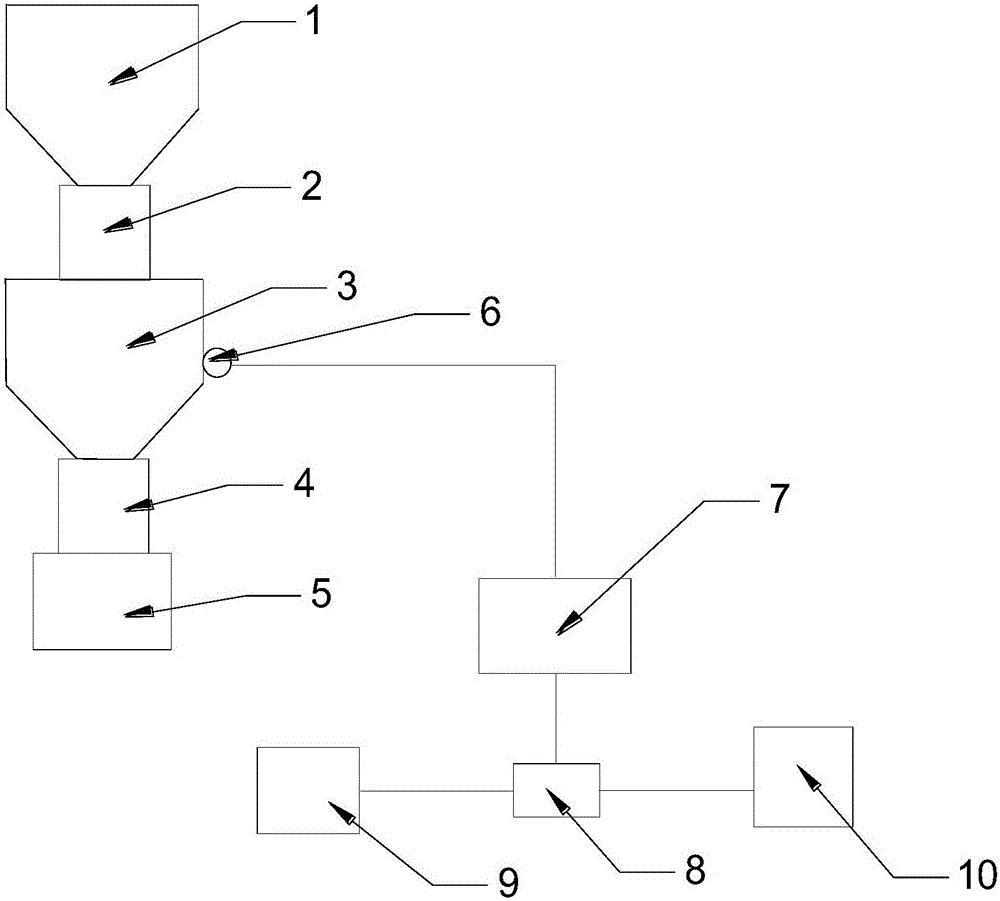

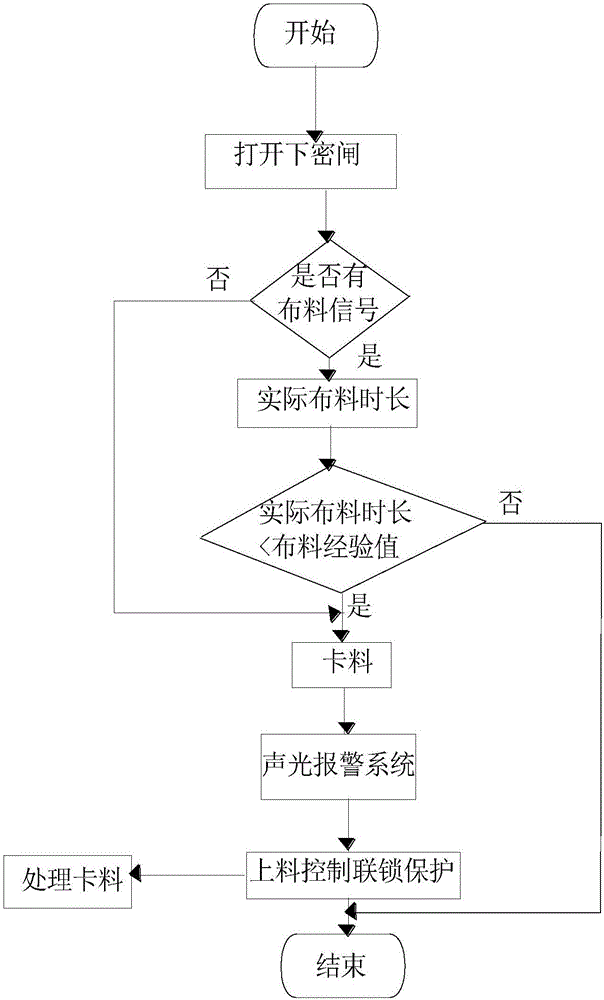

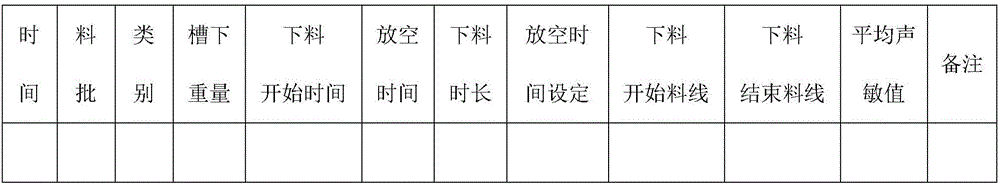

Detection device for material blocking of charging bucket at top of blast furnace and detection method

ActiveCN106350628AEasy to installShort software development cycleBlast furnace detailsChecking devicesProgrammable logic controllerEngineering

The invention discloses a detection device for material blocking of a charging bucket at the top of a blast furnace. The detection device comprises a material receiving hopper, the charging bucket, an airtight box, an acoustic sensor, a switch, an operation computer, a server and a blast furnace PLC (Programmable Logic Controller) control system, wherein the material receiving hopper is arranged at the upper side of the charging bucket; the acoustic sensor is arranged at the outer side of the charging bucket and is connected with the blast furnace PLC control system; the PLC control system is connected to the operation computer and the server through the switch; a material blocking detection system and a sound-light alarming system are developed and designed in the server; the material blocking detection system is connected to the sound-light alarming system. The invention discloses a detection method for the detection device. According to the detection device and the detection method disclosed by the invention, the acoustic sensor is arranged outside the blast furnace charging bucket and is convenient to mount; in addition, the acoustic sensor can work in a production state of the blast furnace. According to the detection device and the detection method disclosed by the invention, the processing efficiency of faults is improved, the downtime and under-blowing time of the blast furnace due to material blocking is shortened, the yield is increased, indexes are optimized, and stable production of the blast furnace is promoted.

Owner:上海宝宬冶金科技有限公司

Fuzzy fault diagnosis and prediction representation method based on size characteristic similarity measurement

ActiveCN110148132AOvercome limitationsAdjust operations in timeImage enhancementImage analysisFeature setState prediction

The invention discloses a fuzzy fault diagnosis and prediction representation method based on size characteristic similarity measurement, belongs to the foam flotation field. The invention discloses afuzzy fault diagnosis method for a flotation process. On the basis of foam visual time sequence feature extraction, a sub-sequence and a sub-mode of a foam time sequence are defined, a historical feature trend information set is established by adopting historical data information, the similarity of real-time trend features and the historical trend feature set is measured, and fuzzy diagnosis is performed on the fault occurrence probability by integrating sequence trend information. According to the method, the concept of fuzzy fault diagnosis is provided, a flotation working condition state prediction representation model is established through reliability sequence selection and abnormal factor establishment, and a new solution is provided for trend judgment and numerical trend possibility. The defect that original foam characteristics statically describe the flotation process is overcome, working condition abnormal symptoms are found in time, the fault possibility at the future moment is displayed in a numerical mode, manual operation is facilitated, and production is stably optimized.

Owner:CENT SOUTH UNIV

Planting method of selenium-enriched Bingtang oranges

InactiveCN109275481AWell developed root systemReduce incubation timeCalcareous fertilisersBio-organic fraction processingAdditive ingredientSweetness

The invention discloses a planting method of selenium-enriched Bingtang oranges. The method comprises the steps of seedling raising, soil preparation, transplanting, field management and picking. Through the adoption of the planting method disclosed by the invention, the planted Bingtang oranges are high in yield, high in sweetness and rich in nutritional ingredients, and the selenium element content is in a range of 54-65 [mu]g / kg. In addition, the planted Bingtang oranges are bright in color and rich in fragrance, and are popular with customers in the market.

Owner:DAXIN SCI & TECH INFORMATION RES INST

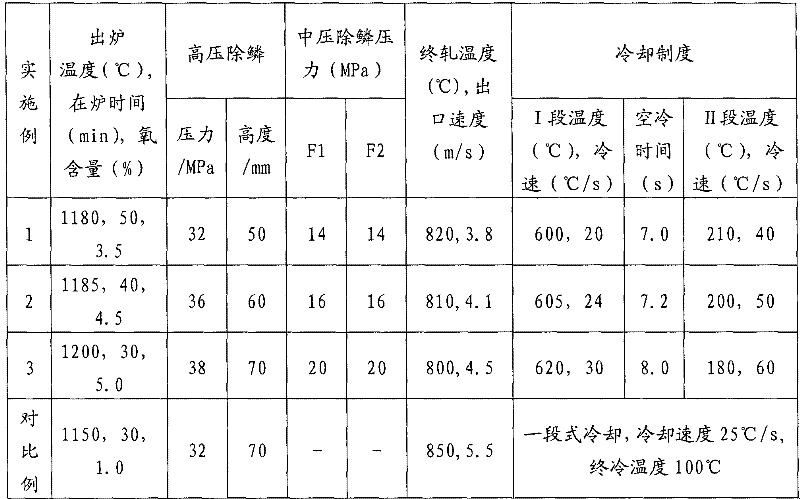

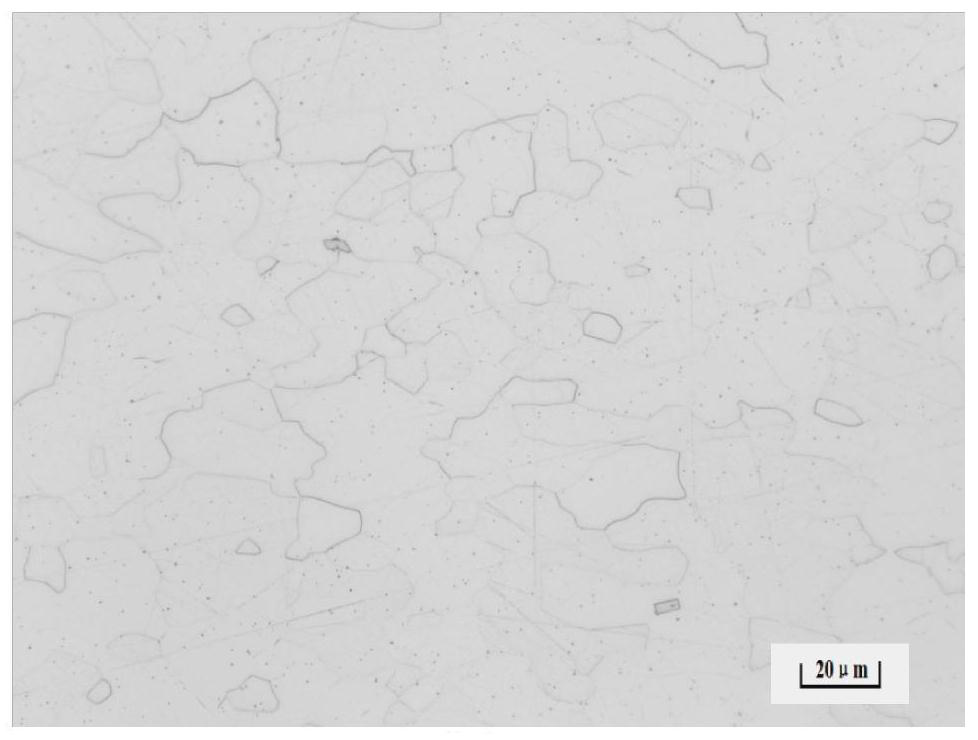

CSP process-based manufacturing method of economical hot-rolled dual-phase steel with high surface quality

ActiveCN101906571BEnough time to stayAvoid it happening againTemperature control deviceWork treatment devicesHigh surfaceHigh pressure water

The invention relates to a CSP process-based manufacturing method of economical hot-rolled dual-phase steel with high surface quality, which solves the problems that the existing economical hot-rolled dual-phase steel has serious surface iron scales and instable structure property control. The technical scheme comprises molten iron desulfurization, converter blowing, argon blowing, refining, continuous casting, soaking, finish rolling, cooling and coiling. The steel comprises the following chemical components in percentage by weight: 0.03 to 0.065 percent of C, 0.45 to 0.55 percent of Si, 1.20 to 1.55 percent of Mn, less than or equal to 0.012 percent of S, less than or equal to 0.020 percent of P, 0.015 to 0.060 percent of Als, and the balance of Fe and inevitable impurities. In the manufacturing method, the plate blank tapping temperature of a soaking furnace is controlled to be between 1,180 and 1,200 DEG C in the soaking step, the oxygen content volume percent in the furnace is 3.5 to 5.0 percent, the time inside the furnace is 30 to 50 minutes, and the plate blank after soaking is subjected to high-pressure water descaling and then is subjected to the finish rolling. The dual-phase steel produced by the manufacturing method has stable structure property control, no obvious iron scales on the surface, and excellent performance indexes.

Owner:武汉钢铁有限公司

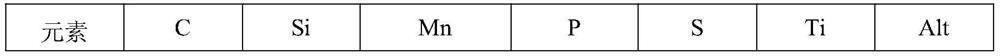

A cold-rolled hot-dip galvanized steel sheet with excellent bending properties and a manufacturing method thereof

ActiveCN112553522BEasy to cleanHigh yieldHot-dipping/immersion processesChemical compositionMetallurgy

The invention relates to a cold-rolled hot-dip galvanized steel sheet with excellent bending performance and a manufacturing method thereof, and mainly solves the problem that the thickness of the prior art is 1.0-1.2 mm and the weight of the single-sided zinc layer is 45-55 g / m 2 The technical problems of poor bending performance and high manufacturing cost of cold-rolled hot-dip galvanized steel sheet. The invention provides a cold-rolled hot-dip galvanized steel sheet with excellent bending performance and a manufacturing method thereof. The chemical composition weight percentages of the substrate are: C: 0.0010-0.0020%, Si: 0-0.034%, Mn: 0.05- 0.15%, P≤0.02%, S≤0.015%, Alt: 0.015~0.05%, Ti: 0.02%~0.025%, the balance is Fe and inevitable impurity elements; After 45°, reverse bending is performed for 180°, d=0a is qualified, and no zinc layer of the hot-dip galvanized steel sheet falls off.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

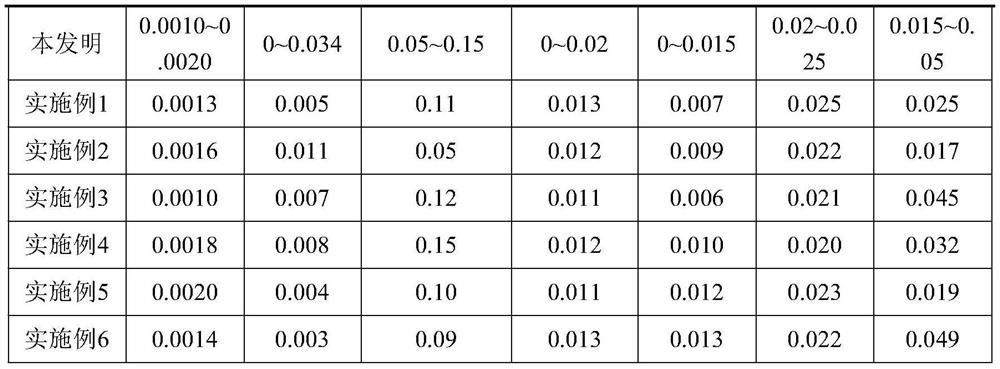

Dispersion assistant for suspension polymerization, method for producing vinyl-based polymer using the same, and vinyl chloride resin

Owner:JAPAN VAM & POVAL

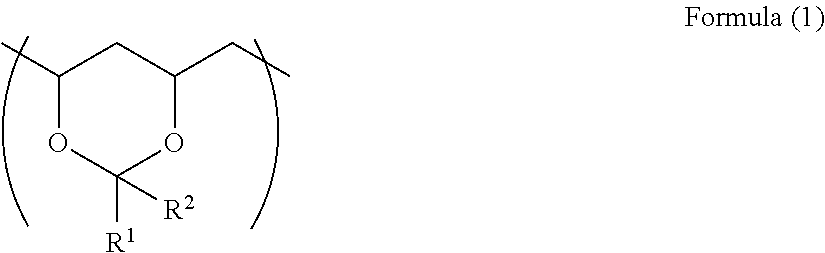

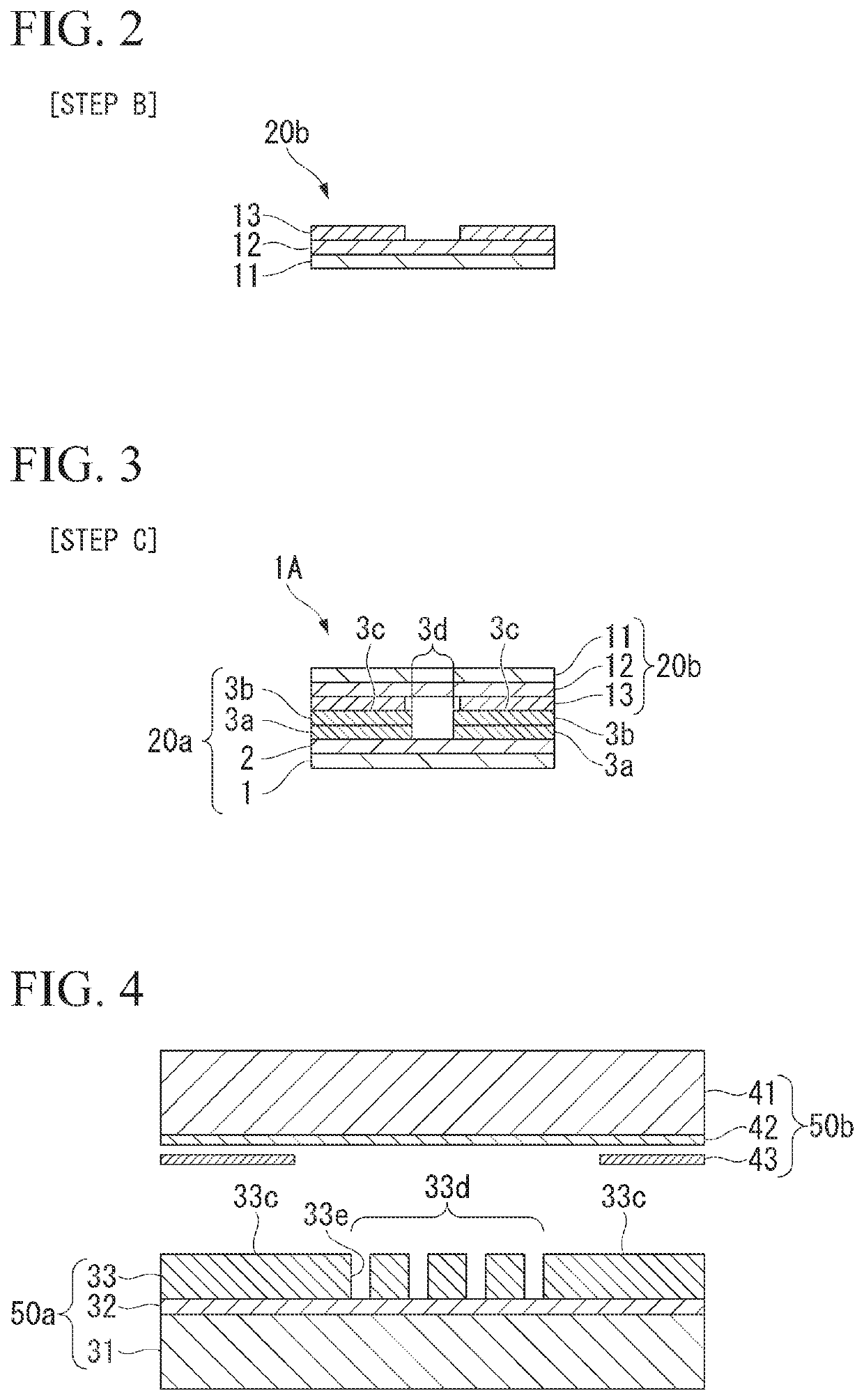

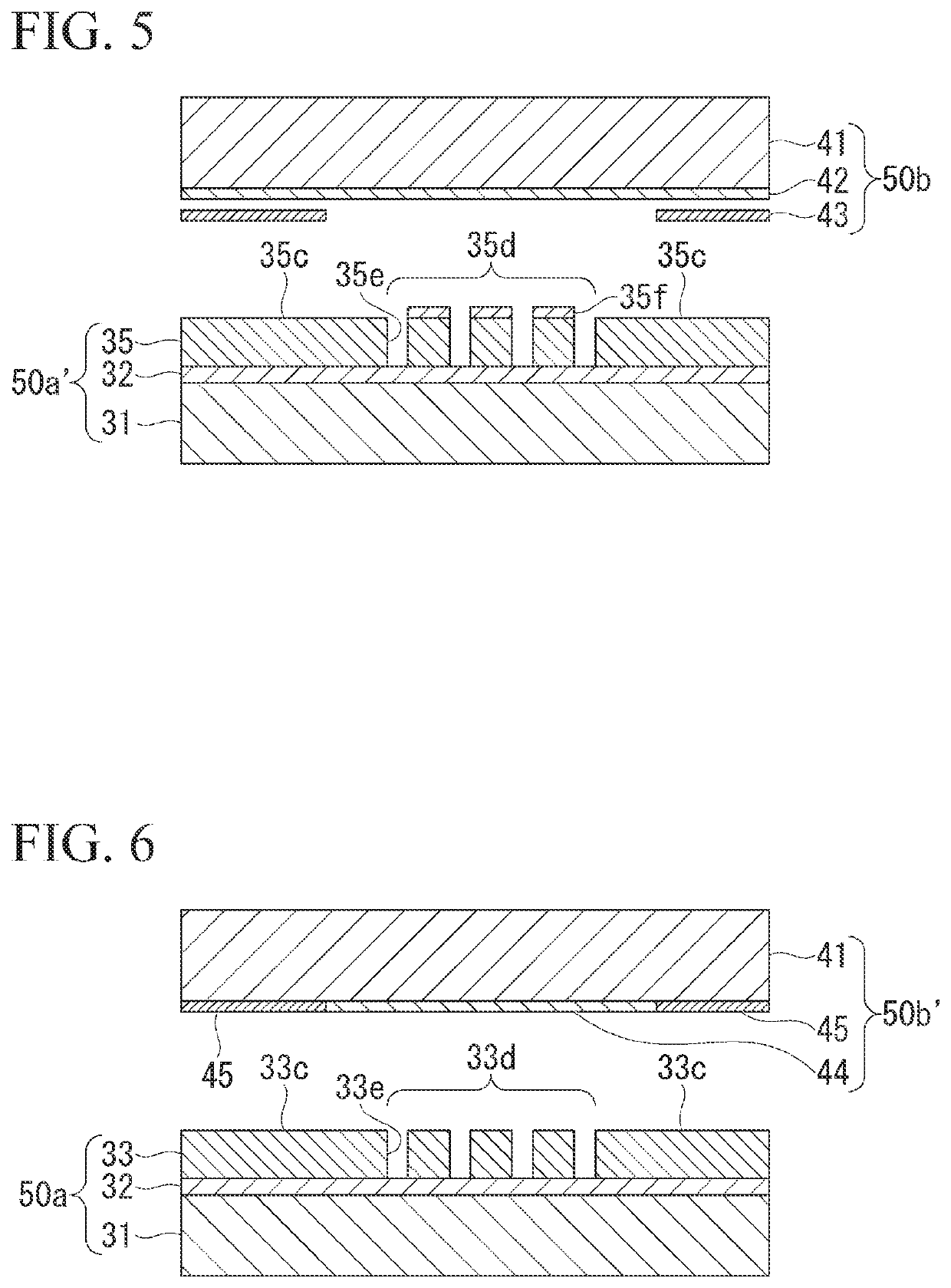

Method of producing cell culture chip

ActiveUS20210222106A1Conducive to stable productionLiquid leakage from the flow path is suppressedAdditive manufacturing apparatusLayered product treatmentPolyesterAdhesive

A method of producing a cell culture chip, in which a first adhesive is film-formed on a first substrate having transparency such that a first adhesive layer and a recessed portion on which one or more cell culture flow paths are formed face each other, and a second adhesive is film-formed on the first substrate such that a second adhesive layer and a flat portion around the recessed portion face each other, thereby obtaining a cell culture flow path substrate, the first adhesive containing a polyester-based resin having a glass transition temperature of 5° C. or higher, and the second adhesive containing a polyester-based resin having a glass transition temperature of lower than 5° C.

Owner:TOKYO OHKA KOGYO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com