Control method of strip steel deviation correction based on finish rolling vertical rolls

A technology of strip deviation and control method, applied in rolling mill control device, metal rolling, metal rolling, etc., can solve the problems of simple control method, unable to adapt to the increasingly diverse product specifications and high quality requirements of products, etc. Product quality, conducive to stable production of hot rolling, and the effect of reducing centerline offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

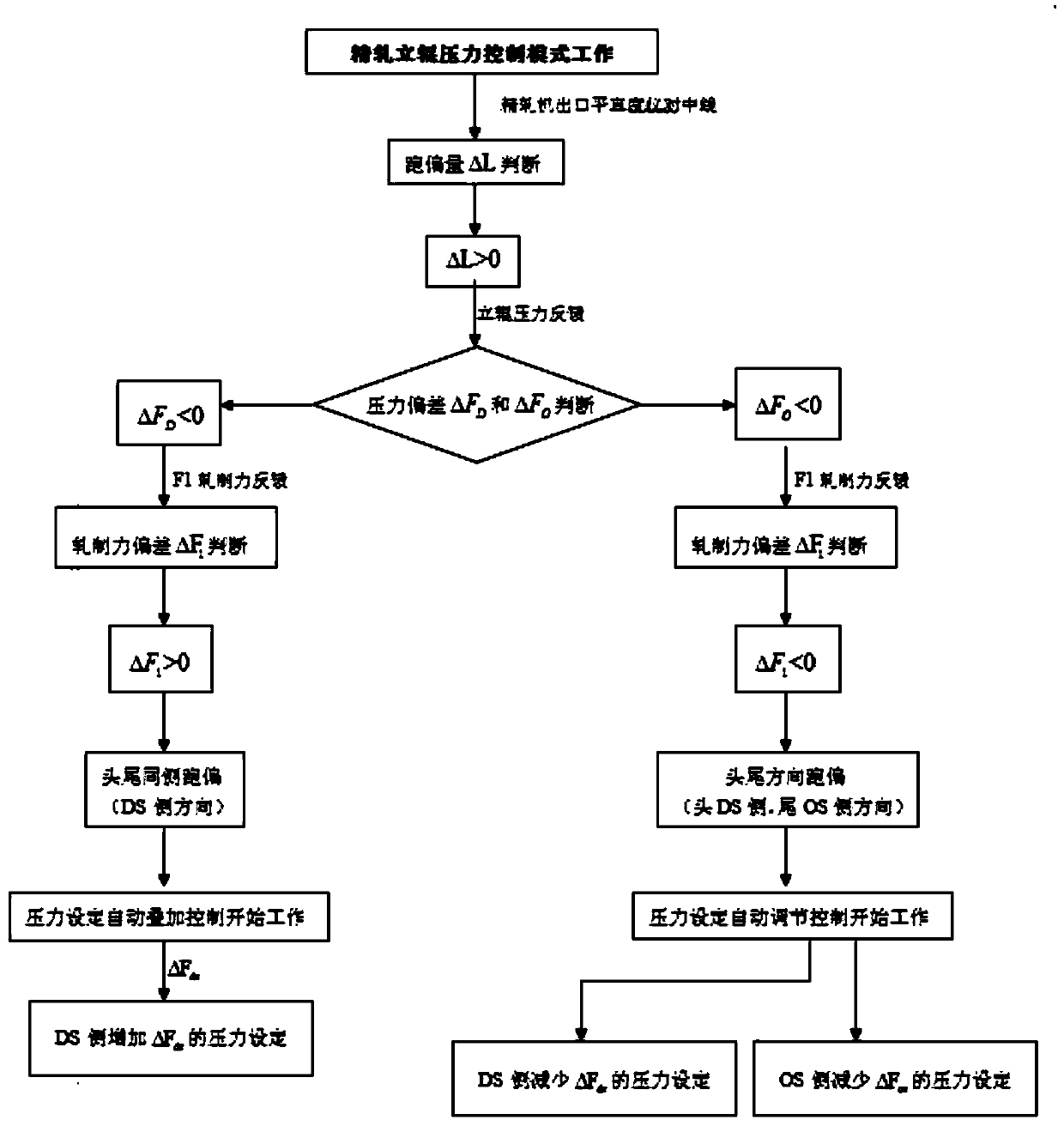

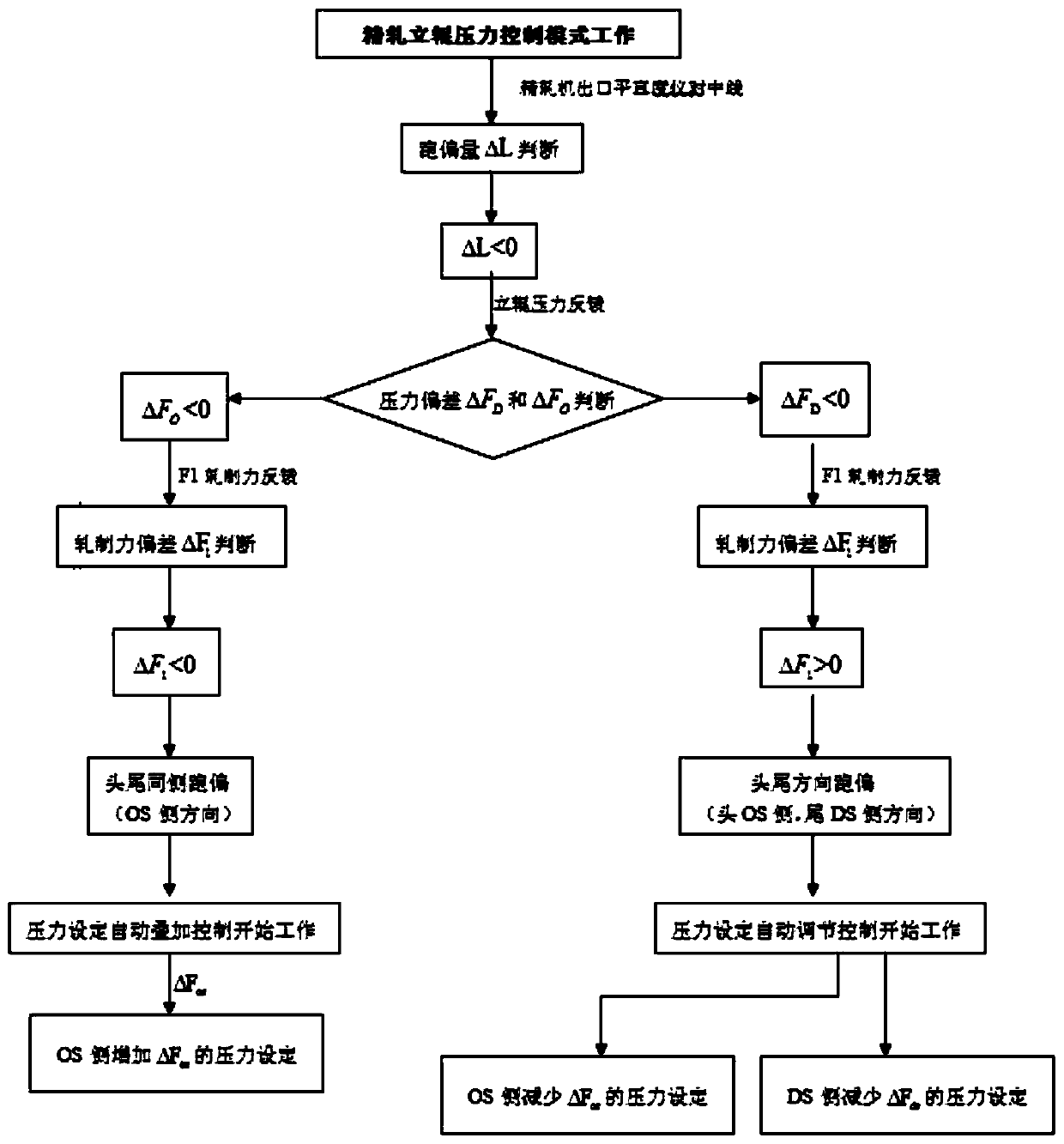

[0042] figure 1 and figure 2 The flow chart of the control method for correcting strip deviation based on the finishing vertical roll provided by the embodiment of the present invention, the method specifically includes the following steps:

[0043] S1. Based on the deviation of the strip rolling line detected at the exit of the finishing mill F7 and the rolling force of the F1 mill, the type of deviation of the strip is judged, including: the deviation of the same side of the head and the tail and the deviation of the head and tail in the opposite direction;

[0044] The deviation type of the strip is judged based on the head an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com