Horizontal type corrective pinch device

A horizontal, pinch roll technology, applied in the field of metallurgical steel rolling machinery, can solve the problems of difficult automatic belt threading, high manufacturing cost, and large floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with specific embodiment, the present invention is further described:

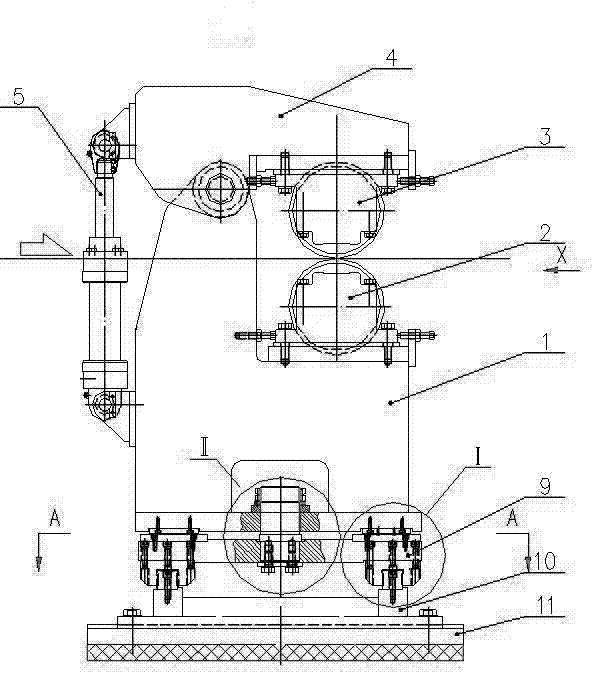

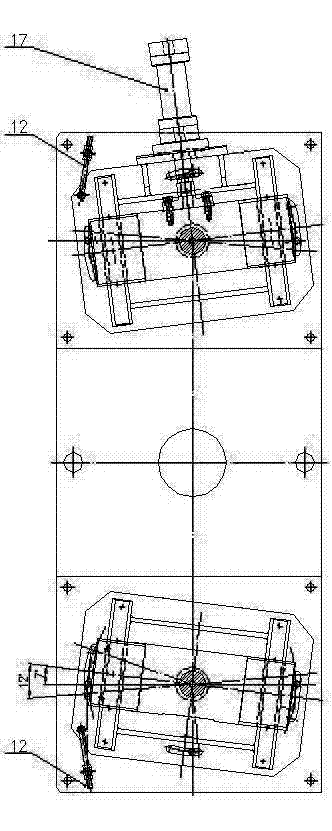

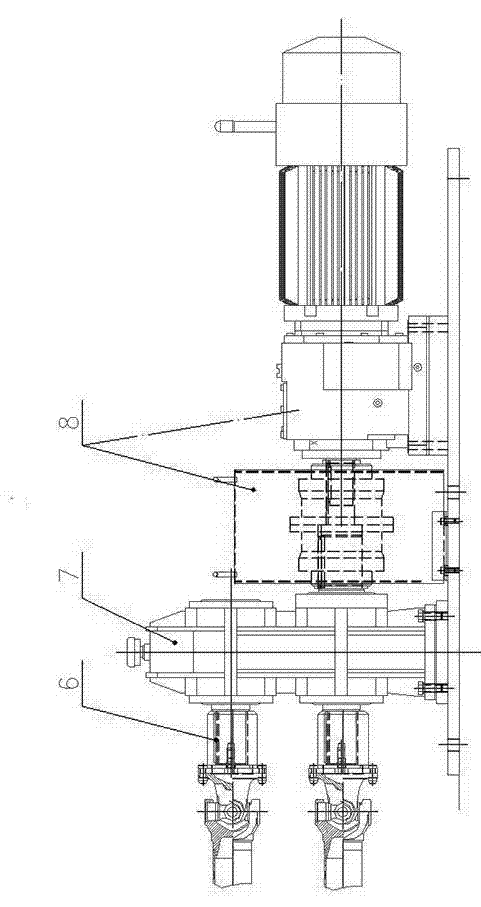

[0027] Such as Figure 1 to Figure 5 The horizontal correction and pinching device shown includes a base 11, a fixed frame 10, a motor and a coupling 8, a pressure roller frame 4, a pressure roller 3, a pinch roller 2, a detection element, and a hydraulic cylinder control system. The fixed frame 10 is connected with the base 11, and can be rotated to adjust the angle. The fixed frame 10 is equipped with a rolling guide rail pair 16, and a mobile frame 1 that can move on the rolling guide rail pair 16. The side of the mobile frame 1 is equipped with a pressure roller frame. Drive the hydraulic cylinder 5, the pressure roller frame 4 is hinged on the mobile frame 1, and is connected with the pressure roller frame drive hydraulic cylinder 5, and can be driven by the pressure roller frame drive hydraulic cylinder 5 to rotate around the hinge point, and the pinch Roller 2 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com