Detection device for material blocking of charging bucket at top of blast furnace and detection method

A detection device and blast furnace technology, applied in the field of blast furnaces, can solve problems such as the lagging response of the radar probe of the material tank, the inability to quantify the material distribution process, and the poor use of the material tank radar, so as to increase production, optimize indicators, and improve failures. The effect of processing efficiency and short software development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

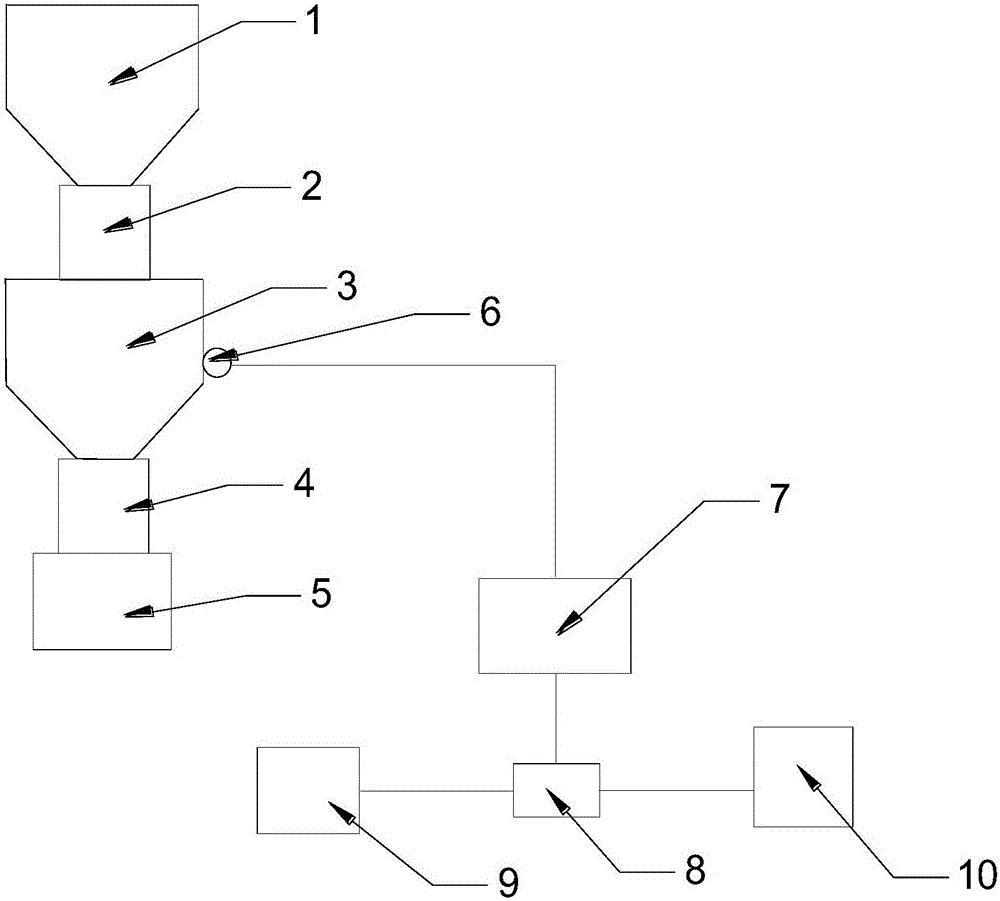

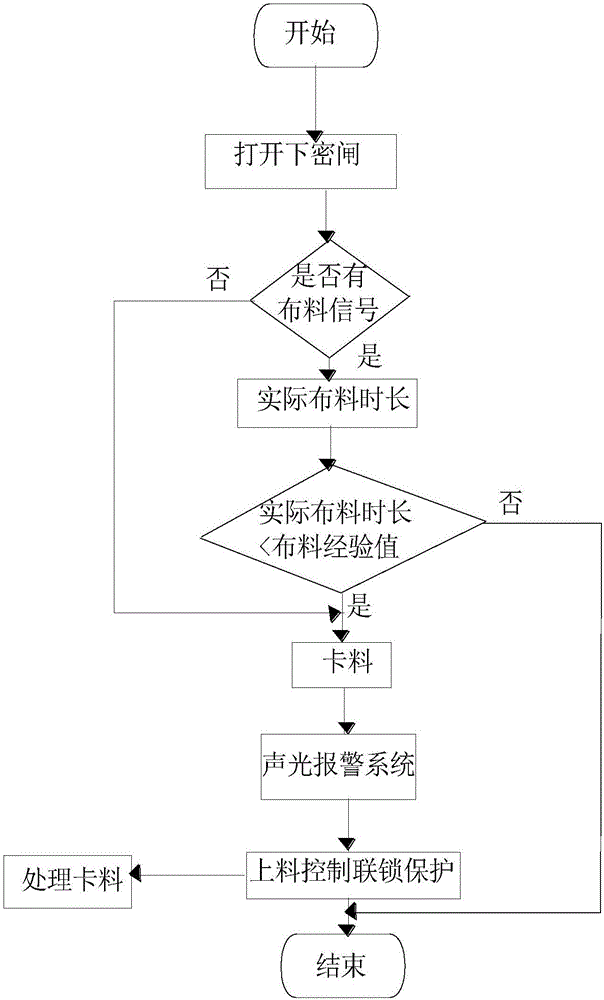

[0019] see Figure 1-2 , a blast furnace top material tank material jam detection device, including a hopper 1, an upper sealing valve 2, a material tank 3, a lower sealing valve 4, an airtight box 5, an acoustic sensor 6, a switch 8, an operating computer 9, and a server 10 and a blast furnace PLC control system 7; the receiving hopper 1 is installed on the upper side of the material tank 3, and the bottom end of the receiving hopper 1 is provided with an upper sealing valve 2, and the upper sealing valve 2 is used to control the feeding of the receiving hopper 1 speed; the airtight box 5 is installed on the lower side of the material tank 3, and a lower sealing valve 4 is arranged between the airtight box 5 and the material tank 3; an acoustic sensor 6 is installed on the outside of the material tank 3, so that The acoustic sensor 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com