Magnetism-weight-flotation combined technology for separating hematite iron ore containing iron carbonate

A combined process and iron carbonate technology, applied in the field of combined magnetic-gravity-floating process, can solve the problems of increasing the production cost of the dressing plant, unstable flotation operation, and high cost of flotation operation, and achieve stable production and reduced production cost. , the effect of reducing the amount of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

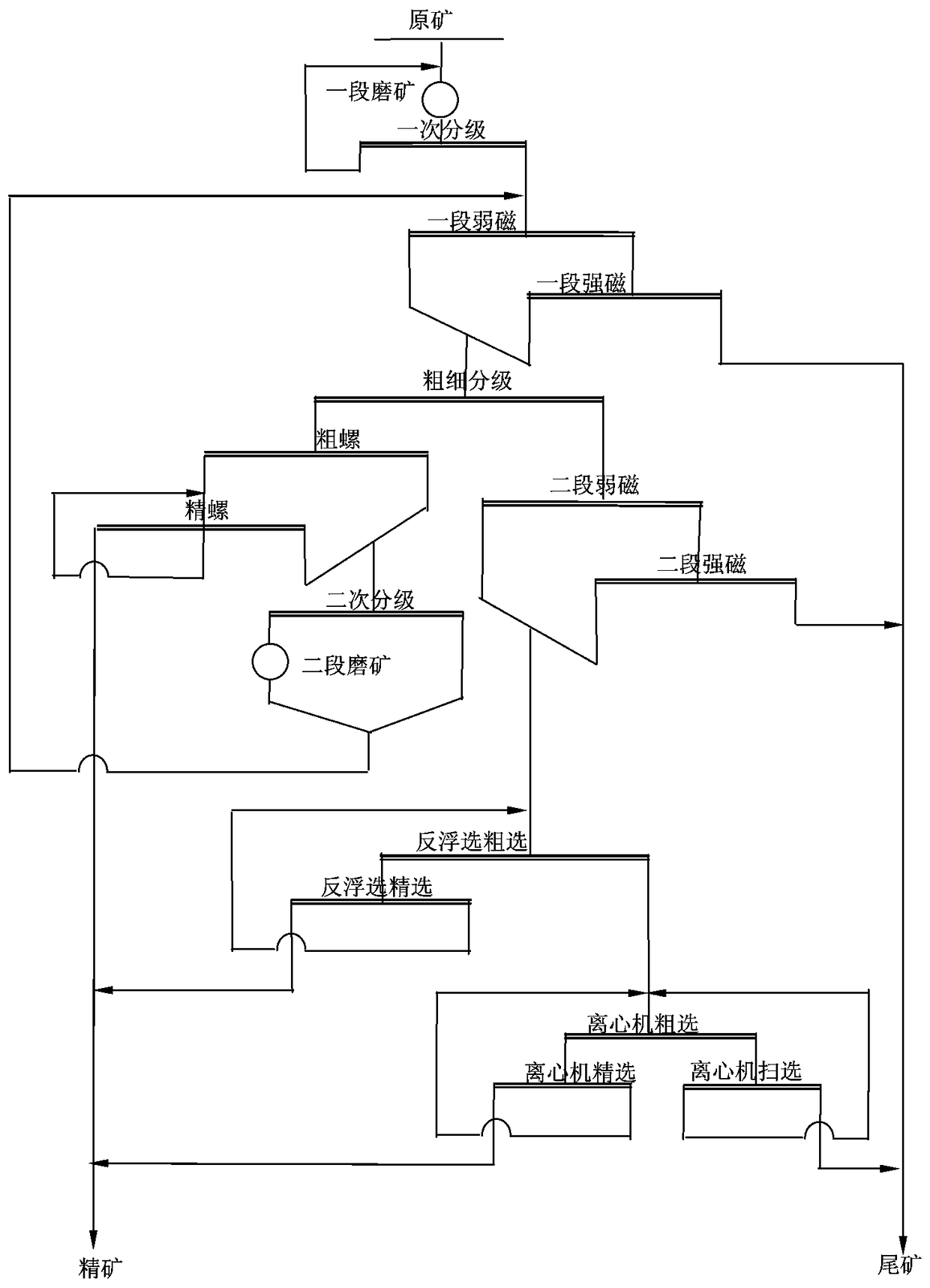

[0024] Such as figure 1 Shown, a kind of magnetic-gravity-flotation combined process of sorting iron carbonate-containing hematite ore of the present invention comprises will be based on hematite, the iron ore of hematite distribution rate 41.58%, grade 29.14% A section of closed-circuit grinding operation is given to obtain a primary classification overflow product with a particle size of -200 mesh and a content of 65.5%, which is characterized in that it also includes the following operations:

[0025] 1) A section of weak magnetic and strong magnetic operation: a section of weak magnetic and strong magnetic operation is composed of a section of weak magnetic and a section of strong magnetic. The primary graded overflow products and middling regrind products are fed into a section of weak magnetic, and a section of weak magnetic tailings is fed into a section Strong ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com