A cold-rolled hot-dip galvanized steel sheet with excellent bending properties and a manufacturing method thereof

A manufacturing method and hot-dip aluminum technology are applied to cold-rolled hot-dip aluminum-zinc steel sheets, hot-dip aluminum-zinc steel sheets, cold-rolled hot-dip aluminum-zinc steel sheets and their manufacturing fields, and can solve the bending of cold-rolled hot-dip aluminum-zinc steel sheets. The problems of poor performance and high manufacturing cost can achieve the effect of low switching difficulty, low implementation investment, and stable production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

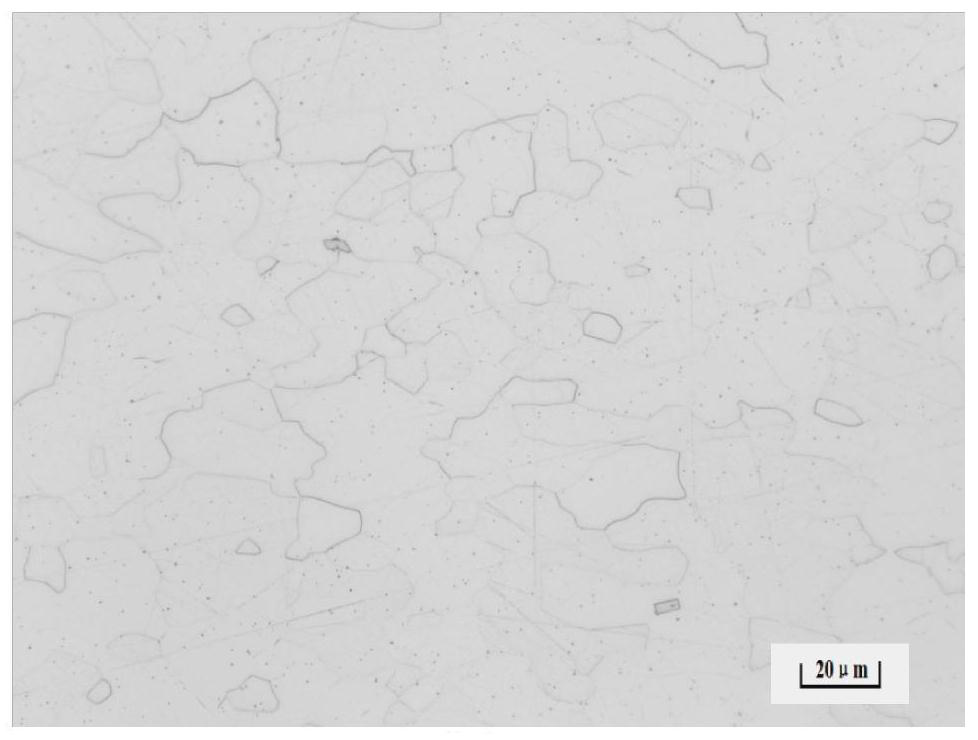

[0048] The present invention will be further described below in conjunction with Embodiments 1 to 6. .

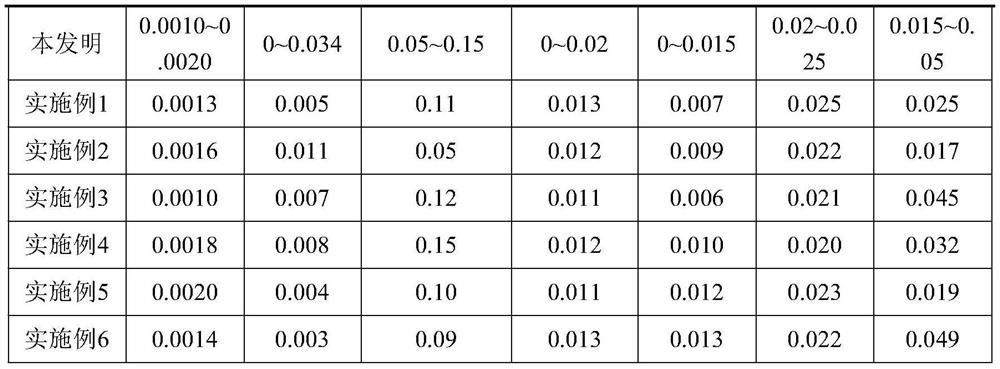

[0049] Table 1 is the chemical composition (by weight percent) of the cold-rolled hard steel sheet of the embodiment of the present invention, and the balance is Fe and inevitable impurities.

[0050] The chemical composition of table 1 embodiment steel of the present invention, unit: weight percentage

[0051]

[0052]

[0053] Through converter smelting, continuous casting slabs meeting the required chemical composition are obtained, with a thickness of 210 to 240 mm, a width of 800 to 1300 mm, and a length of 5000 to 10000 mm.

[0054] The continuous casting slab is heated to 1150-1200 ℃ by a heating furnace and then hot rolled. The hot rolling is a two-stage rolling process. The rough rolling is 5-pass continuous rolling, and the finishing rolling is 7-pass continuous rolling. The temperature at the end of rolling is 900°C to 920°C; the laminar cooling adopts po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com