Positive material of high-voltage lithium ion battery, lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, applied in the manufacture of electrolyte batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of poor high-rate discharge performance, oxygen defects in spinel structures, and difficulty in making single equivalence, achieving Effect of high thermal stability, good stability, good structural stability and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

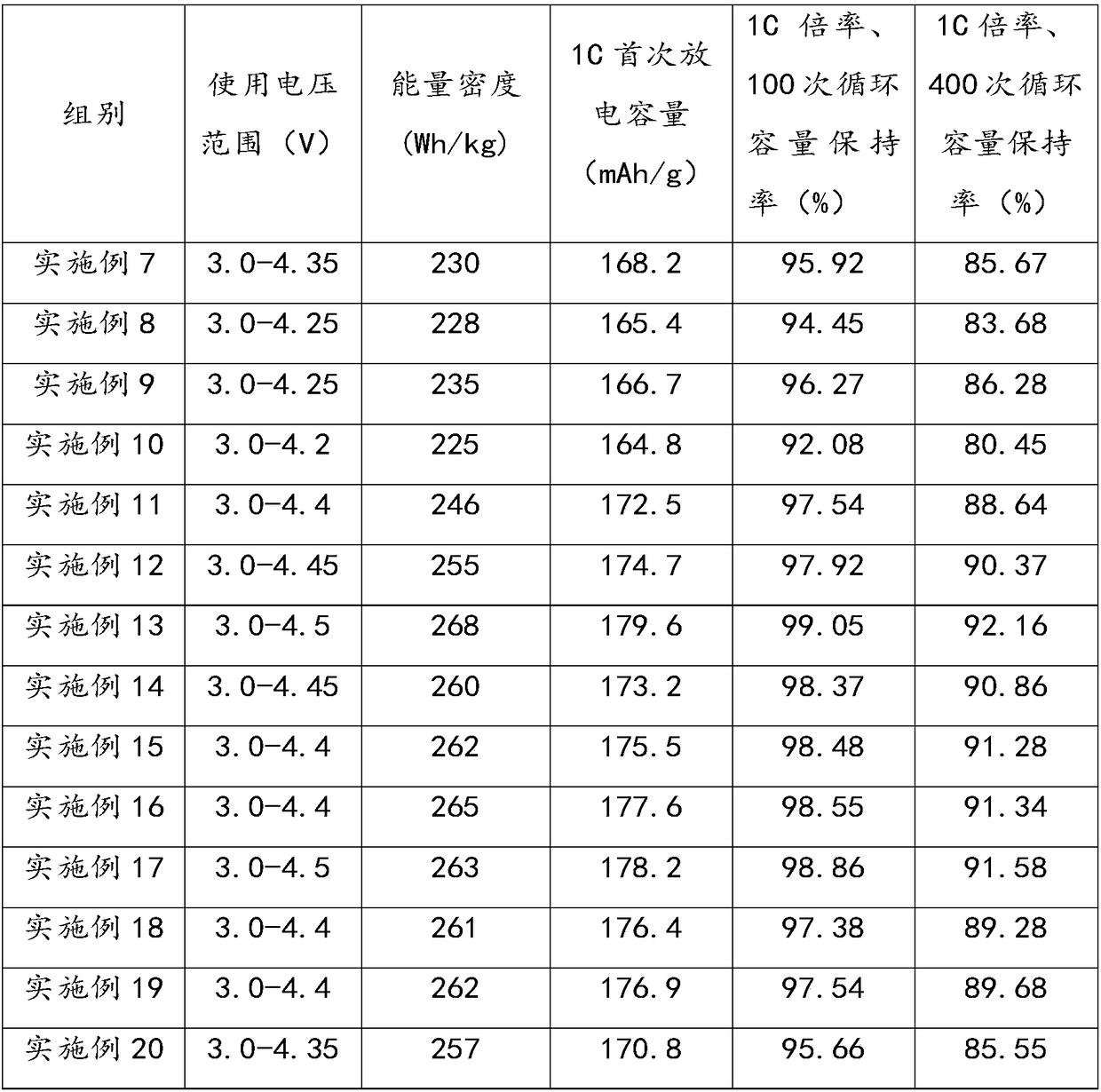

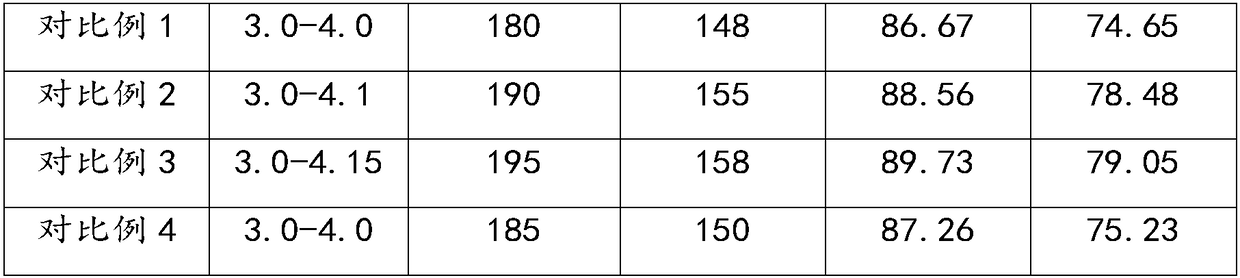

Examples

preparation example Construction

[0080] In a third aspect, a method for preparing the aforementioned lithium-ion battery is provided, comprising the following steps:

[0081] (a) fully mixing each raw material in the negative electrode material to obtain a negative electrode material slurry, uniformly coating the negative electrode material slurry on the surface of the negative electrode current collector, and then drying and compacting to form a negative electrode sheet;

[0082] (b) fully mixing each raw material in the positive electrode material to obtain a positive electrode material slurry, uniformly coating the positive electrode material slurry on the surface of the positive electrode current collector, and then drying and compacting to form a positive electrode sheet;

[0083] (c) Assemble the positive electrode sheet, negative electrode sheet, separator and electrolyte to obtain a lithium ion battery.

[0084] The above-mentioned lithium ion battery structurally includes a casing, a positive electro...

Embodiment 1

[0091] A high-voltage lithium battery positive electrode material, including the following raw materials in weight percentage: 92% of positive electrode active material with single crystal structure, 4% of conductive carbon black and 4% of PVDF;

[0092] The structural formula of the positive electrode active material with single crystal structure is LiNi 0.5 co 0.2 mn 0.3 o 2 .

Embodiment 2

[0094] A high-voltage lithium battery positive electrode material, including the following raw materials in weight percentage: 95% of positive electrode active material with single crystal structure, 2.5% of conductive carbon black and 2.5% of PVDF;

[0095] The structural formula of the positive electrode active material with single crystal structure is LiNi 0.5 co 0.2 mn 0.3 o 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com