Automatic filling system and automatic filling method for low-temperature liquid storage tank

A low-temperature liquid and automatic technology, applied in gas/liquid distribution and storage, pipeline system, mechanical equipment, etc., can solve unfavorable factory manual arrangements and normal operation, risks to employees' personal safety, accidents in cold pumps and filling, etc. problem, to achieve the effect of improving product loading efficiency, alleviating the tension of on-duty personnel, and reducing labor pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

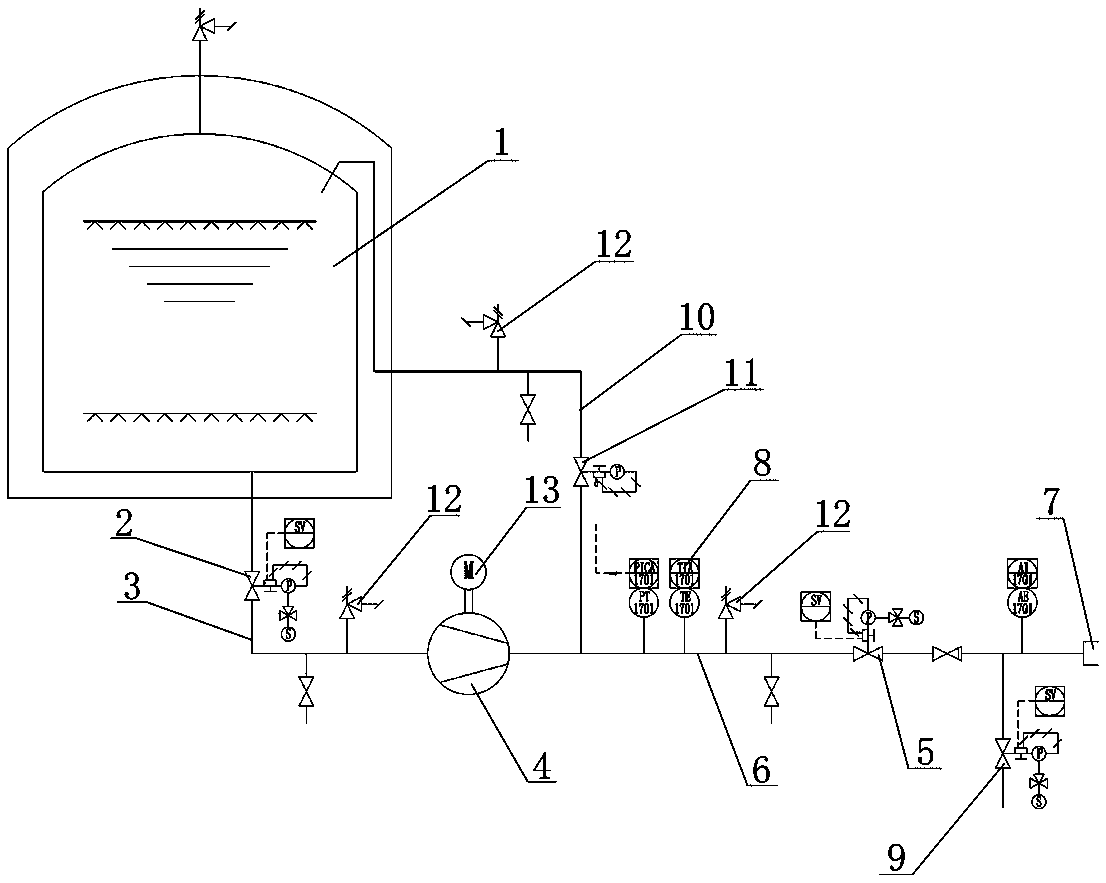

[0013] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, an automatic filling system for a low-temperature liquid storage tank according to the present invention, the low-temperature liquid storage tank 1 is connected to a liquid filling vehicle pump 4 through an automatic filling inlet valve 2 and a first connecting pipe 3, The liquid car filling pump 4 is connected to the filling port 7 through an automatic filling outlet valve 5 and a second connecting pipe 6; the automatic filling inlet valve 2, the liquid car filling pump 4 and the automatic filling outlet valve 5 are respectively It is connected and controlled with the center console of the peripheral equipment, and the center console is also connected with multiple on-site video monitors 8 and various instrument measuring points.

[0014] As shown in the figure, the first connecting pipe 3 and the second connecting pipe 6 between the automatic filling in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com